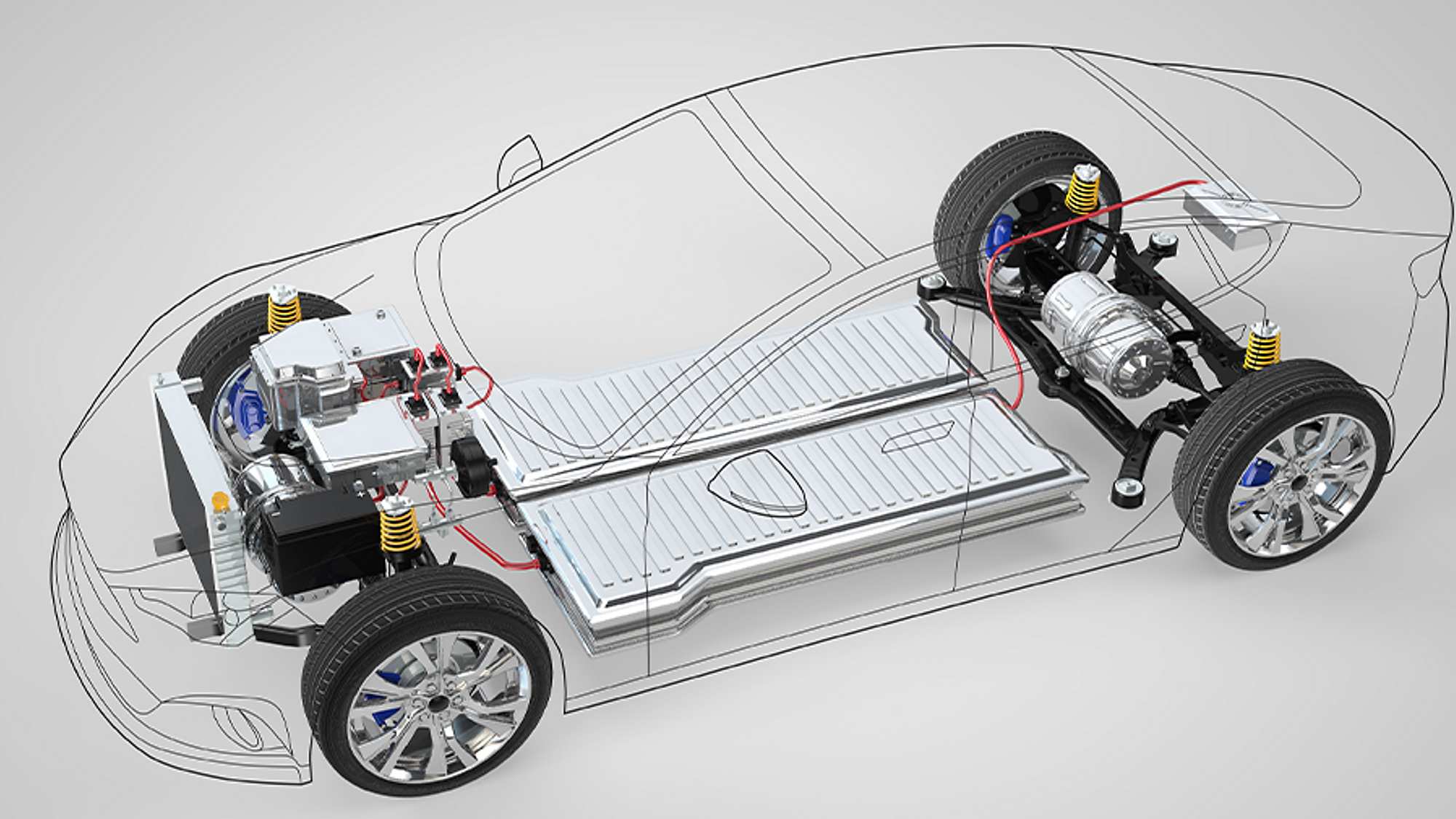

Faced with growing climate and regulatory pressures, the automotive industry is investing billions into advancing electromobility, launching an impressive number of new electric and hybrid cars every year. Moving forward, we can expect to see a rising number of electrified vehicles on the streets – ranging from mild and full hybrids through plug-in hybrids to fully electric cars. In this decade, we will reach the point where the majority of all newly produced cars worldwide have a partially or fully electric powertrain. Up to 50 percent of all vehicles are expected to be driven by a partially or fully electric powertrain by 20301.

1 | Source: IHS

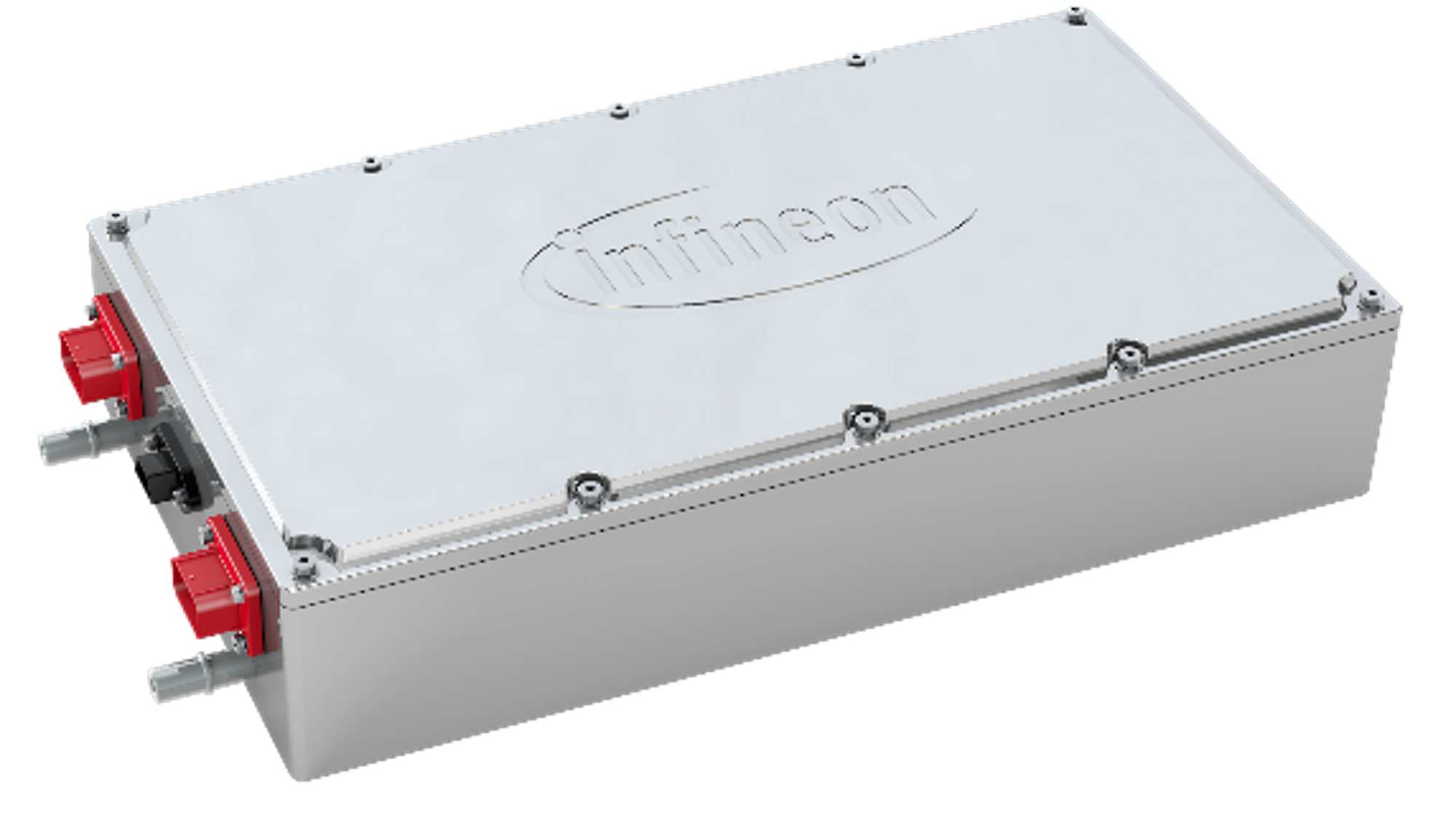

As a world leader in automotive electronics, Infineon’s semiconductors are at the heart of vehicle electrification and the enabling infrastructure. They are helping to build energy efficiency into all steps of the energy supply chain and thus support all electrification scenarios. Our innovative portfolio has the right fit for all design challenges, extending from individual chips through discrete components to complete modules in silicon and silicon carbide technologies.

With our proven system approach and rich offering, we give carmakers a valuable edge in such a dynamic and competitive marketplace. Our scalable electromobility chipsets, including sensors, microcontrollers, gate drivers and power semiconductors, help to reduce system costs across all performance classes.

Customers around the world can rely on our local support teams to simplify design efforts and accelerate time-to-market for their e-mobility solutions.

Building on decades of experience in automotive semiconductors, we also know exactly what our customers need to transition towards electric drivetrains. Designed to give our customers peace of mind, our solutions are developed, manufactured and qualified exclusively for the automotive market and reach beyond common automotive industry standards. Our proven track record demonstrates that we systematically exceed the current AEC qualification standard to achieve zero defects over a product lifetime of 15-plus years.

In addition, as the largest and most reliable supplier of electromobility chips, we recently invested in our 300 mm plant in Villach to increase our manufacturing capacity in alignment with our customers’ business growth plans. Our volume capabilities and flexibility mean that we are ideally placed to meet our customers’ current and future electromobility business development strategies.

Discover our broad semiconductor portfolio for electric vehicles, hybrid electric vehicles and plug-in hybrid electric vehicles (xEV) along with our application solutions for key components such as the main inverter, the battery management system and the on-board charger (OBC).

The on-board charger (OBC) – also known as an on-board battery charger – re-charges the high-voltage battery in a plug-in hybrid electric vehicle (PHEV) or a battery-powered electric vehicle (EV) directly from the grid while the car is parked and connected to a charging station/pile.

Typically, the power flow from the grid to the battery is unidirectional, but there are cases where bidirectionality is required (battery to load or battery to grid).

- Where: at home or at the office

- How often: everyday

- How long: more than 3h

- Main harbour charging is a must for battery electric vehicles (BEV) and plug-in hybrid electric vehicles (PHEV)

- Where: supermarket, cinema, restraurant, etc.

- How often: once-twice a week

- How long: less than 3h

- Destination charging is nice to have for BEV and PHEV

- Where: highway, travel routes

- How often: depending on driver

- How long: less than 30min

- Range extension charging is a must for BEV

Main harbor charging at home or at the office is the key use case for OBCs. Most EVs are charged slowly overnight at the driver’s home using a convenient power outlet in a garage or similar. Charging at home has the advantage of extending the battery life and availing of off-peak grid prices.

Main harbor charging at home or at the office is the key use case for OBCs. Most EVs are charged slowly overnight at the driver’s home using a convenient power outlet in a garage or similar. Charging at home has the advantage of extending the battery life and availing of off-peak grid prices.

In this video you will see, how charging works inside a car, you will get familiar with the concept of an on-board charger (OBC) and the different charging categories and you will recognize the requirements for on-board charging and identify different power topologies.

Infineon's new automotive CoolSiC™ 1200 V MOSFETs offer low electrical losses and exceptional robustness for automotive power conversion applications.

Infineon's Automotive CoolSiC™ 650 V Schottky diodes are ideal for the PFC stage in OBC and auxiliary systems, providing superior efficiency and robustness for automotive designs.

The new CoolMOS™ CFD7A SJ MOSFET family from Infineon elevates electric vehicle efficiency and reliability, making it well-suited for OBC and HV-LV DC-DC converters in automotive applications.

Infineon’s Automotive OptiMOS™ Portfolio offers low RDS(on) MOSFETs with optimized gate thresholds and a wide range of package variants, catering to xEV applications.

Infineon’s TRENCHSTOP™ 5 AUTO IGBT technology redefines “best-in-class” IGBT performance by providing unmatched efficiency for hard-switching applications.

Infineon's EasyPACK™ 1B modules provide benefits like easy mounting, PressFIT technology, reliable isolation, traceability, NTC sensing, and low stray inductance.

The EiceDRIVER™ galvanically isolated dual-channel IGBT driver IC (e.g. 2ED020I12FAXUMA2) from Infineon comes with embedded desaturation protection and embedded gate clamping for unipolar supply operations. It supports unipolar or bipolar supply modes.

OPTIREG™ Linear and Switcher

Infineon OPTIREG™ portfolio is specially designed to fit into harsh automotive requirements. Especially the new products such as Linear Voltage Regulators of new series TLS850 or the new OPTIREG™ Switcher are designed to support wider qualification profiles of new applications.

OPTIREG™ PMIC

Infineon’s TLF35584 is a multiple output system supply for safety-relevant applications supplying 3.3 V microcontrollers, transceivers and sensors based on an efficient and flexible pre-/post-regulator concept over a wide input voltage range. The wide switching frequency range optimizes efficiency and enables designers to use small filter components.

High Speed CAN transceiver

The TLE9251VSJ is the latest Infineon high-speed (HS) CAN transceiver generation, used inside HS CAN networks in automotive and industrial applications. It supports CAN FD data frames at 5 Mbits/s with wake-up capability and is fully compliant with ISO11898-2 (2016).

Lite SBC

The TLE9251VSJ is the latest Infineon high-speed (HS) CAN transceiver generation, used inside HS CAN networks in automotive and industrial applications. It supports CAN FD data frames at 5 Mbits/s with wake-up capability and is fully compliant with ISO11898-2 (2016).

Infineon’s AURIX™ 32-bit microcontroller family (SAK-TC275TP-64F200N DC, SAK-TC265D-40F200N BC, SAK-TC234LP-32F200N AC and SAK-TC224L-16F133N AC) provides a scalable portfolio that supports automotive safety standard ISO 26262. The embedded hardware security model (HSM) enables secure communications. AURIX™ highlights include an optimized peripheral set including ADC & timers for electromobility applications.

OPTIGA™ TPM SLI 9670 security controller comes flashed with securely coded firmware. This combined hardware/software turnkey solution offers a rich set of security features to save both design and testing effort. It is certified to Common Criteria EAL4+ and FIPS 140-2. Other highlights include an extended temperature range and AEC Q100 qualification.

Batteries are used to power everything from smartphones and power tools to electric vehicles. Depending on the required energy and associated dis-/charge currents, the battery pack is an assembly of individual li-ion cells connected in series and in parallel. A battery cell delivers approximately 4 V. A complete 400 V battery pack, for instance, features about 100 cells. As the cell chemistry is very sensitive to the exact dis-/charge current, voltage profile and temperature profile, the battery requires special monitoring and control capabilities. This is the role of the battery management system (BMS). The BMS monitors and balances each cell. It senses temperature, pressure, current and voltage, measures charge capacity (by counting coulombs) and tracks many other diagnostic metrics. Based on these parameters, it calculates – among other things - the state of charge (SoC), the state of health (SoH) and the precise consumption to predict how much energy is left for the application.

In addition, the BMS controls the main switch to protect the battery against critical overloads. In the event of thermal runaway, the BMS can derate or shut the battery down.

Charged for success

Charged for success

Discover how our semiconductor solutions for battery management systems can help you get the most out of your battery while achieving the highest quality and functional safety standards.

Cell Monitoring Controller

The controller performs cell-level monitoring according to pre-adjusted voltages and temperatures using parallel high-precision ADCs for each cell in order to guarantee synchronous measurements. It controls charge balancing across multiple cells and offers advanced housekeeping functionality for periodically scheduled cell measurements and state analysis as well as alarms required for functional safety. This includes protection against over-/undervoltage and thermal stress. The monitoring controller is designed for extreme low-power and can be supplied directly from the monitored cells.

Visit product pages:

Functionally Safe Battery Controller

Our AURIXTM microcontrollers enable functionally safe operation of the battery under all conditions and stress scenarios. They optimize the battery’s operational safety margins in order to withdraw maximum energy for longer rides and better cell lifetime. These controllers are available over a wide operating range, covering basic functions such as BMS calibration. They also support high-end functions such as SoC and SoH checks. Other highlights include special protective responses in the event of a crash or mechanical strain and a main protection switch to disconnect the battery in the event of an emergency. Furthermore, as the battery is an important and expensive asset of the vehicle, AURIX™ also includes the HSM for security to prevent illegal manipulation in situations such as tuning or to prevent billing fraud.

AURIX™ microcontrollers:

Visit the product family page:

Protection Switch

The protection switch is a key safety element, enabling the battery to be disconnected in a controlled manner in the event of an emergency (risk of over-charging, short circuit or thermal run-away). If the switching characteristic of the relay is fast enough, it could also be used in traction applications to enable pre-charging of the main inverter DC bus without additional components. Our TLE9104SH relay driver is a smart 4-channel low-side switch in smart power technology with an 16-bit SPI for control and diagnosis. All channels are protected against overcurrent/overtemperature and have active clamping circuitry.

Visit product page:

Current & Isolation Monitoring

Isolation monitoring is a key functional safety feature for high-voltage batteries. Alongside short circuit and overload current measurements, the voltage of the high-voltage DC+/- lines is continuously measured against the pack’s mechanical housing and the surrounding chassis. High-performance current sensors enable the current measurements captured to be also used for other battery monitoring and advanced battery diagnostics functions such as state-of-charge and depth-of-discharge calculations.

(commercial/industrial qualified version only)

Condition Sensing

Advanced analytics are also performed at pack level with respect to thermal, electrical and mechanical strain. Highly accurate pressure sensing can detect extensions to the cell housing as a result of overload/overcharge conditions as well as mechanical impacts on the pack‘s mechanical structure. Sensing of evaporated CO2 from the cell’s electrolyte as a result of cell aging or overstress could be a vital indicator of battery health. Finally a combination of pressure and position sensors allows unauthorized pack manipulations to be detected.

Visit Product Page:

- Pressure

- 3D Position

- CO2 (commercial/industrial qualified version only)

Electronic Power Supply

BMS electronic components such as controllers, sensors and gate drivers rely on integrated smart power supplies to operate the digital/analog/power ICs. Our auxiliary power supply components are available with full ISO26262 compliance for ASIL applications. They provide multiple voltage levels to supply the full system. In addition, they supply a dedicated reference voltage for highly accurate and load-independent ADC supplies. Our OPTIREG™ automotive power supply ICs, the TLF35584 for functional safe supplies or OPTIREG™ switcher with 1 – 6 channel buck-boost DCDC supplies give designers maximum flexibility.

Visit product families:

OPTIREG™ automotive power supply ICs for linear, switcher and PMIC devices:

- OPTIREG™ PMIC

- OPTIREG™ Switcher

- S6BP20x (1-Ch Buck-Boost DC/DC), S6BP50x (3-Ch Buck-Boost DC/DC), S6BP40x (6-Ch Buck-Boost DC/DC)

Communication Transceiver

Standard network protocols like CAN (Controller Area Network) and FlexRay are used for data exchange between the battery and external applications. Especially in vehicle battery applications, safety-related self-testing and monitoring functions increase the amount of time-critical data exchanged between the BMS and the ECUs. The automotive industry established the CAN FD (Flexible Data rate) protocol to accelerate CAN communications up to 5 Mbit/s, and the CAN PN (Partial Networking) method to improve energy efficiency. Our broad portfolio of automotive transceivers supports these protocols and methods while meeting and even exceeding the latest ESD and EMC requirements.

Thermal Management

Active thermal control is essential with high-voltage li-Ion batteries to avoid accelerated aging, reduced capacity even damage to the battery.

We offer various embedded motor controllers with in-built diagnostic functions supporting active thermal control solutions at pack level. These motor controls come in the smallest form factors with a minimum number of external components so they can be integrated close to the motor. They are based on our 32-bit microcontroller with embedded non-volatile memory, analog/digital peripherals, communication interfaces and integrated current-controlled bridge drivers.

Identification and Security

Cryptographic measures such as secured storage of certificates and keys help ensure that the battery management system “is only doing what it is supposed to do”. Cryptographic technologies can securely encrypt over-the-wire/-air software updates, store BMS-related sensitive data such as usage profiles, identify genuine or authenticated parts and components, and verify that a battery configuration remains within its intended design and operational limits. In addition, they can contribute to business success by protecting the IP of core BMS operation software.

For more technical information, please visit our battery management system application page.

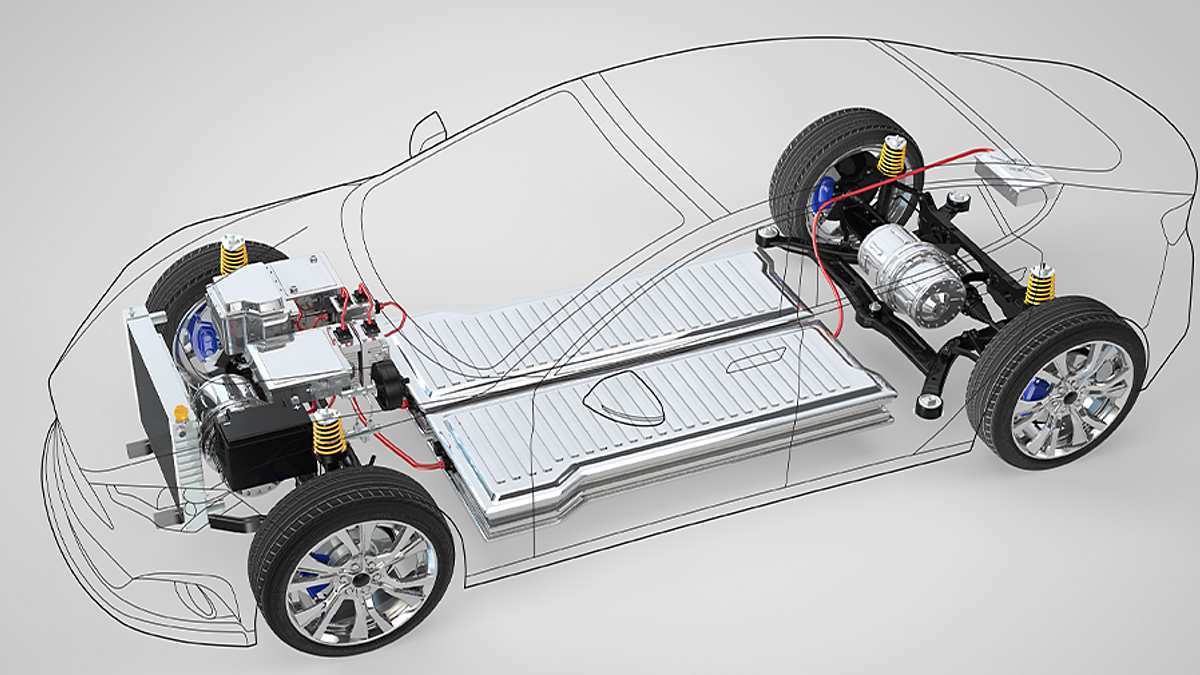

A main inverter – also known as traction inverter –controls the electric motor, converting DC to the AC needed to power the engine. The inverter can change the speed at which the motor rotates by adjusting the AC frequency.

We have an extensive, cost-effective offering of automotive-qualified silicon and silicon-carbide (SiC) discrete semiconductors and solutions supporting a wide range of motors, generators and power classes – all designed to increase inverter energy efficiency (through lower power losses) while shrinking size and weight. This scalable, highly reliable portfolio includes everything from IGBTs, MOSFETs and diodes through IGBT and MOSFET gate drivers to AURIX™ automotive microcontrollers.

See how we are increasing the cost and power efficiency of main inverter designs. Discover our end-to-end Si and SiC offering, including IGBTs, high-voltage drivers, microcontrollers and sensors.

IGBT Modules

Our portfolio comprises cutting-edge IGBT power modules in different product families, configurations, current ratings as well as IGBT chip generations for an almost infinite number of applications. The well-known 62 mm, Easy and Econo families, IHM / IHV B-series, PrimePACK™ and XHP™ power modules are all equipped with the latest IGBT technologies. They come in chopper, dual, PIM, four-pack, six-pack, twelve-pack, 3-level, booster and single switch configurations with a current rating between 6 A and 3600 A. IGBT modules cover a range from only hundreds of watts to several megawatts.

IGBT Module HybridPack™ Drive - NEW

Our HybridPACK™ Drive family allows designers to scale hybrid and electric inverters across different segments and performance classes in an easy and cost-efficient way. The portfolio consists of five different products (380 A/1200 V, 660 A/750 V, 770 A/750 V, 820 A/750 V, 950 A/750 V) – all with the same footprint. Our EDT2 IGBT technology offers best-in-class efficiency and robustness. Recently, we extended this product family with the following new devices: FS820R08A6P2BBPSA1, FS950R08A6P2BBPSA1, FS380R12A6T4BBPSA1, FS770R08A6P2BBPSA1 and FS660R08A6P2BBPSA1.

IGBT Discretes

Striving for the highest standards in performance and quality, Infineon offers a comprehensive discrete IGBT portfolio that is second to none. New products are application-specific developed to achieve the highest value. They cover voltage classes from 600V up to 1200V, cover a wide range of current ratings as well as different packages.

Discrete-based inverters are known for being flexible, scalable, and cost-efficient systems. Due to their adaptable form factor, discrete devices provide a significant advantage for system integration. Parallelizing devices to reach different power classes enables a scalable inverter platform.

The new automotive IGBT discrete AIKQ200N75CP2 & AIKQ120N75CP2 are super efficient EDT2 IGBTs with co-packed diodes, designed for main inverter systems. The AIKQ200N75CP2 sets a new benchmark for component power density in a TO-247PLUS package.

Our comprehensive portfolio of automotive-qualified gate driver ICs (EiceDRIVER™) helps simplify design and optimize performance in all FET and IGBT driving stages. Available also in SiC technology, our drivers support power ranges from 12 V up to 1200 V, extending from plug-and-play solutions to SPI devices offering full configuration flexibility.

The 1EDI2004AS device offers galvanic isolation up to 1200 V using our proven coreless transformer technology. It also comes with protective and diagnostic features for ISO26262 functional safety compliance. Other family members: 1EDI2002AS, 1EDI2010AS, 1EBN1001AE, 1ED020I12FA2, 1ED020I12FTA and 2ED020I12FA.

PMIC / OPTIREG™

Our OPTIREG™ PMIC products are designed for integrated, multi-rail power supply in harsh automotive environments, especially in electrical drivetrains. OPTIREG™ PMICs offer highly efficient voltage regulation across pre- and post-regulator architectures featuring DCDC, linear and tracking regulators. Integrated monitoring and supervision features support compliance with functional safety standard ISO26262 up to ASIL-D at system level (as a SEooC). The TLF35584 is the device of choice for main inverters.

CAN Transceiver

CAN (Control Area Network) serial bus with multi-master capabilities was originally developed for use in automobiles with data rates of up to 1 Mbps as defined by the ISO 11898 international standard. Because of its ability to function in harsh automotive environments, CAN has found its way into different applications in modern vehicles. These include body, safety, powertrain and infotainment systems.

2G AURIX™ microcontroller

The AURIX™ TC2xx family is based on single- and multicore 32-bit TriCore™ CPUs, all designed to meet the highest safety standards while also increasing performance.

AURIX™ gives developers one single platform for powertrain and safety applications, significantly reducing effort to achieve the ASIL-D standard than with classical lockstep architectures. Thanks to its unique features, AURIX™ is the perfect match for powertrain applications (including electrical and hybrid vehicles). The devices of choice for high-performance main inverter applications are the TC38x.

1G AURIX™ microcontroller

The AURIX™ TC3xx combines performance with a powerful safety architecture, making this family the ideal fit for automotive applications. The family concept includes scalable feature sets and pin-outs for optimal flexibility. Highlights include a multicore architecture and medium EVITA support.

Available in single or dual sensor versions with AMR or GMR technology, this XENSIV™ position sensor is automotive qualified (Q100, Grade 1: -40°C to 125°C ambient temperature) and is a green product (RoHS compliant). It offers low current consumption and quick start-up and features separate supply pins for the top and bottom sensor. Inverter design highlights include 180°(AMR) and 360°(GMR) contactless angle measurement, a high-speed analog sensor, high angular accuracy, low delay, stray field robustness and suitability for iEoS (integrated end of shaft) designs.

For more technical information, please visit our Main Inverter application page.

The on-board charger (OBC) – also known as an on-board battery charger – re-charges the high-voltage battery in a plug-in hybrid electric vehicle (PHEV) or a battery-powered electric vehicle (EV) directly from the grid while the car is parked and connected to a charging station/pile.

Typically, the power flow from the grid to the battery is unidirectional, but there are cases where bidirectionality is required (battery to load or battery to grid).

- Where: at home or at the office

- How often: everyday

- How long: more than 3h

- Main harbour charging is a must for battery electric vehicles (BEV) and plug-in hybrid electric vehicles (PHEV)

- Where: supermarket, cinema, restraurant, etc.

- How often: once-twice a week

- How long: less than 3h

- Destination charging is nice to have for BEV and PHEV

- Where: highway, travel routes

- How often: depending on driver

- How long: less than 30min

- Range extension charging is a must for BEV

Main harbor charging at home or at the office is the key use case for OBCs. Most EVs are charged slowly overnight at the driver’s home using a convenient power outlet in a garage or similar. Charging at home has the advantage of extending the battery life and availing of off-peak grid prices.

Main harbor charging at home or at the office is the key use case for OBCs. Most EVs are charged slowly overnight at the driver’s home using a convenient power outlet in a garage or similar. Charging at home has the advantage of extending the battery life and availing of off-peak grid prices.

In this video you will see, how charging works inside a car, you will get familiar with the concept of an on-board charger (OBC) and the different charging categories and you will recognize the requirements for on-board charging and identify different power topologies.

Infineon's new automotive CoolSiC™ 1200 V MOSFETs offer low electrical losses and exceptional robustness for automotive power conversion applications.

Infineon's Automotive CoolSiC™ 650 V Schottky diodes are ideal for the PFC stage in OBC and auxiliary systems, providing superior efficiency and robustness for automotive designs.

The new CoolMOS™ CFD7A SJ MOSFET family from Infineon elevates electric vehicle efficiency and reliability, making it well-suited for OBC and HV-LV DC-DC converters in automotive applications.

Infineon’s Automotive OptiMOS™ Portfolio offers low RDS(on) MOSFETs with optimized gate thresholds and a wide range of package variants, catering to xEV applications.

Infineon’s TRENCHSTOP™ 5 AUTO IGBT technology redefines “best-in-class” IGBT performance by providing unmatched efficiency for hard-switching applications.

Infineon's EasyPACK™ 1B modules provide benefits like easy mounting, PressFIT technology, reliable isolation, traceability, NTC sensing, and low stray inductance.

The EiceDRIVER™ galvanically isolated dual-channel IGBT driver IC (e.g. 2ED020I12FAXUMA2) from Infineon comes with embedded desaturation protection and embedded gate clamping for unipolar supply operations. It supports unipolar or bipolar supply modes.

OPTIREG™ Linear and Switcher

Infineon OPTIREG™ portfolio is specially designed to fit into harsh automotive requirements. Especially the new products such as Linear Voltage Regulators of new series TLS850 or the new OPTIREG™ Switcher are designed to support wider qualification profiles of new applications.

OPTIREG™ PMIC

Infineon’s TLF35584 is a multiple output system supply for safety-relevant applications supplying 3.3 V microcontrollers, transceivers and sensors based on an efficient and flexible pre-/post-regulator concept over a wide input voltage range. The wide switching frequency range optimizes efficiency and enables designers to use small filter components.

High Speed CAN transceiver

The TLE9251VSJ is the latest Infineon high-speed (HS) CAN transceiver generation, used inside HS CAN networks in automotive and industrial applications. It supports CAN FD data frames at 5 Mbits/s with wake-up capability and is fully compliant with ISO11898-2 (2016).

Lite SBC

The TLE9251VSJ is the latest Infineon high-speed (HS) CAN transceiver generation, used inside HS CAN networks in automotive and industrial applications. It supports CAN FD data frames at 5 Mbits/s with wake-up capability and is fully compliant with ISO11898-2 (2016).

Infineon’s AURIX™ 32-bit microcontroller family (SAK-TC275TP-64F200N DC, SAK-TC265D-40F200N BC, SAK-TC234LP-32F200N AC and SAK-TC224L-16F133N AC) provides a scalable portfolio that supports automotive safety standard ISO 26262. The embedded hardware security model (HSM) enables secure communications. AURIX™ highlights include an optimized peripheral set including ADC & timers for electromobility applications.

OPTIGA™ TPM SLI 9670 security controller comes flashed with securely coded firmware. This combined hardware/software turnkey solution offers a rich set of security features to save both design and testing effort. It is certified to Common Criteria EAL4+ and FIPS 140-2. Other highlights include an extended temperature range and AEC Q100 qualification.

Batteries are used to power everything from smartphones and power tools to electric vehicles. Depending on the required energy and associated dis-/charge currents, the battery pack is an assembly of individual li-ion cells connected in series and in parallel. A battery cell delivers approximately 4 V. A complete 400 V battery pack, for instance, features about 100 cells. As the cell chemistry is very sensitive to the exact dis-/charge current, voltage profile and temperature profile, the battery requires special monitoring and control capabilities. This is the role of the battery management system (BMS). The BMS monitors and balances each cell. It senses temperature, pressure, current and voltage, measures charge capacity (by counting coulombs) and tracks many other diagnostic metrics. Based on these parameters, it calculates – among other things - the state of charge (SoC), the state of health (SoH) and the precise consumption to predict how much energy is left for the application.

In addition, the BMS controls the main switch to protect the battery against critical overloads. In the event of thermal runaway, the BMS can derate or shut the battery down.

Charged for success

Charged for success

Discover how our semiconductor solutions for battery management systems can help you get the most out of your battery while achieving the highest quality and functional safety standards.

Cell Monitoring Controller

The controller performs cell-level monitoring according to pre-adjusted voltages and temperatures using parallel high-precision ADCs for each cell in order to guarantee synchronous measurements. It controls charge balancing across multiple cells and offers advanced housekeeping functionality for periodically scheduled cell measurements and state analysis as well as alarms required for functional safety. This includes protection against over-/undervoltage and thermal stress. The monitoring controller is designed for extreme low-power and can be supplied directly from the monitored cells.

Visit product pages:

Functionally Safe Battery Controller

Our AURIXTM microcontrollers enable functionally safe operation of the battery under all conditions and stress scenarios. They optimize the battery’s operational safety margins in order to withdraw maximum energy for longer rides and better cell lifetime. These controllers are available over a wide operating range, covering basic functions such as BMS calibration. They also support high-end functions such as SoC and SoH checks. Other highlights include special protective responses in the event of a crash or mechanical strain and a main protection switch to disconnect the battery in the event of an emergency. Furthermore, as the battery is an important and expensive asset of the vehicle, AURIX™ also includes the HSM for security to prevent illegal manipulation in situations such as tuning or to prevent billing fraud.

AURIX™ microcontrollers:

Visit the product family page:

Protection Switch

The protection switch is a key safety element, enabling the battery to be disconnected in a controlled manner in the event of an emergency (risk of over-charging, short circuit or thermal run-away). If the switching characteristic of the relay is fast enough, it could also be used in traction applications to enable pre-charging of the main inverter DC bus without additional components. Our TLE9104SH relay driver is a smart 4-channel low-side switch in smart power technology with an 16-bit SPI for control and diagnosis. All channels are protected against overcurrent/overtemperature and have active clamping circuitry.

Visit product page:

Current & Isolation Monitoring

Isolation monitoring is a key functional safety feature for high-voltage batteries. Alongside short circuit and overload current measurements, the voltage of the high-voltage DC+/- lines is continuously measured against the pack’s mechanical housing and the surrounding chassis. High-performance current sensors enable the current measurements captured to be also used for other battery monitoring and advanced battery diagnostics functions such as state-of-charge and depth-of-discharge calculations.

(commercial/industrial qualified version only)

Condition Sensing

Advanced analytics are also performed at pack level with respect to thermal, electrical and mechanical strain. Highly accurate pressure sensing can detect extensions to the cell housing as a result of overload/overcharge conditions as well as mechanical impacts on the pack‘s mechanical structure. Sensing of evaporated CO2 from the cell’s electrolyte as a result of cell aging or overstress could be a vital indicator of battery health. Finally a combination of pressure and position sensors allows unauthorized pack manipulations to be detected.

Visit Product Page:

- Pressure

- 3D Position

- CO2 (commercial/industrial qualified version only)

Electronic Power Supply

BMS electronic components such as controllers, sensors and gate drivers rely on integrated smart power supplies to operate the digital/analog/power ICs. Our auxiliary power supply components are available with full ISO26262 compliance for ASIL applications. They provide multiple voltage levels to supply the full system. In addition, they supply a dedicated reference voltage for highly accurate and load-independent ADC supplies. Our OPTIREG™ automotive power supply ICs, the TLF35584 for functional safe supplies or OPTIREG™ switcher with 1 – 6 channel buck-boost DCDC supplies give designers maximum flexibility.

Visit product families:

OPTIREG™ automotive power supply ICs for linear, switcher and PMIC devices:

- OPTIREG™ PMIC

- OPTIREG™ Switcher

- S6BP20x (1-Ch Buck-Boost DC/DC), S6BP50x (3-Ch Buck-Boost DC/DC), S6BP40x (6-Ch Buck-Boost DC/DC)

Communication Transceiver

Standard network protocols like CAN (Controller Area Network) and FlexRay are used for data exchange between the battery and external applications. Especially in vehicle battery applications, safety-related self-testing and monitoring functions increase the amount of time-critical data exchanged between the BMS and the ECUs. The automotive industry established the CAN FD (Flexible Data rate) protocol to accelerate CAN communications up to 5 Mbit/s, and the CAN PN (Partial Networking) method to improve energy efficiency. Our broad portfolio of automotive transceivers supports these protocols and methods while meeting and even exceeding the latest ESD and EMC requirements.

Thermal Management

Active thermal control is essential with high-voltage li-Ion batteries to avoid accelerated aging, reduced capacity even damage to the battery.

We offer various embedded motor controllers with in-built diagnostic functions supporting active thermal control solutions at pack level. These motor controls come in the smallest form factors with a minimum number of external components so they can be integrated close to the motor. They are based on our 32-bit microcontroller with embedded non-volatile memory, analog/digital peripherals, communication interfaces and integrated current-controlled bridge drivers.

Identification and Security

Cryptographic measures such as secured storage of certificates and keys help ensure that the battery management system “is only doing what it is supposed to do”. Cryptographic technologies can securely encrypt over-the-wire/-air software updates, store BMS-related sensitive data such as usage profiles, identify genuine or authenticated parts and components, and verify that a battery configuration remains within its intended design and operational limits. In addition, they can contribute to business success by protecting the IP of core BMS operation software.

For more technical information, please visit our battery management system application page.

A main inverter – also known as traction inverter –controls the electric motor, converting DC to the AC needed to power the engine. The inverter can change the speed at which the motor rotates by adjusting the AC frequency.

We have an extensive, cost-effective offering of automotive-qualified silicon and silicon-carbide (SiC) discrete semiconductors and solutions supporting a wide range of motors, generators and power classes – all designed to increase inverter energy efficiency (through lower power losses) while shrinking size and weight. This scalable, highly reliable portfolio includes everything from IGBTs, MOSFETs and diodes through IGBT and MOSFET gate drivers to AURIX™ automotive microcontrollers.

See how we are increasing the cost and power efficiency of main inverter designs. Discover our end-to-end Si and SiC offering, including IGBTs, high-voltage drivers, microcontrollers and sensors.

IGBT Modules

Our portfolio comprises cutting-edge IGBT power modules in different product families, configurations, current ratings as well as IGBT chip generations for an almost infinite number of applications. The well-known 62 mm, Easy and Econo families, IHM / IHV B-series, PrimePACK™ and XHP™ power modules are all equipped with the latest IGBT technologies. They come in chopper, dual, PIM, four-pack, six-pack, twelve-pack, 3-level, booster and single switch configurations with a current rating between 6 A and 3600 A. IGBT modules cover a range from only hundreds of watts to several megawatts.

IGBT Module HybridPack™ Drive - NEW

Our HybridPACK™ Drive family allows designers to scale hybrid and electric inverters across different segments and performance classes in an easy and cost-efficient way. The portfolio consists of five different products (380 A/1200 V, 660 A/750 V, 770 A/750 V, 820 A/750 V, 950 A/750 V) – all with the same footprint. Our EDT2 IGBT technology offers best-in-class efficiency and robustness. Recently, we extended this product family with the following new devices: FS820R08A6P2BBPSA1, FS950R08A6P2BBPSA1, FS380R12A6T4BBPSA1, FS770R08A6P2BBPSA1 and FS660R08A6P2BBPSA1.

IGBT Discretes

Striving for the highest standards in performance and quality, Infineon offers a comprehensive discrete IGBT portfolio that is second to none. New products are application-specific developed to achieve the highest value. They cover voltage classes from 600V up to 1200V, cover a wide range of current ratings as well as different packages.

Discrete-based inverters are known for being flexible, scalable, and cost-efficient systems. Due to their adaptable form factor, discrete devices provide a significant advantage for system integration. Parallelizing devices to reach different power classes enables a scalable inverter platform.

The new automotive IGBT discrete AIKQ200N75CP2 & AIKQ120N75CP2 are super efficient EDT2 IGBTs with co-packed diodes, designed for main inverter systems. The AIKQ200N75CP2 sets a new benchmark for component power density in a TO-247PLUS package.

Our comprehensive portfolio of automotive-qualified gate driver ICs (EiceDRIVER™) helps simplify design and optimize performance in all FET and IGBT driving stages. Available also in SiC technology, our drivers support power ranges from 12 V up to 1200 V, extending from plug-and-play solutions to SPI devices offering full configuration flexibility.

The 1EDI2004AS device offers galvanic isolation up to 1200 V using our proven coreless transformer technology. It also comes with protective and diagnostic features for ISO26262 functional safety compliance. Other family members: 1EDI2002AS, 1EDI2010AS, 1EBN1001AE, 1ED020I12FA2, 1ED020I12FTA and 2ED020I12FA.

PMIC / OPTIREG™

Our OPTIREG™ PMIC products are designed for integrated, multi-rail power supply in harsh automotive environments, especially in electrical drivetrains. OPTIREG™ PMICs offer highly efficient voltage regulation across pre- and post-regulator architectures featuring DCDC, linear and tracking regulators. Integrated monitoring and supervision features support compliance with functional safety standard ISO26262 up to ASIL-D at system level (as a SEooC). The TLF35584 is the device of choice for main inverters.

CAN Transceiver

CAN (Control Area Network) serial bus with multi-master capabilities was originally developed for use in automobiles with data rates of up to 1 Mbps as defined by the ISO 11898 international standard. Because of its ability to function in harsh automotive environments, CAN has found its way into different applications in modern vehicles. These include body, safety, powertrain and infotainment systems.

2G AURIX™ microcontroller

The AURIX™ TC2xx family is based on single- and multicore 32-bit TriCore™ CPUs, all designed to meet the highest safety standards while also increasing performance.

AURIX™ gives developers one single platform for powertrain and safety applications, significantly reducing effort to achieve the ASIL-D standard than with classical lockstep architectures. Thanks to its unique features, AURIX™ is the perfect match for powertrain applications (including electrical and hybrid vehicles). The devices of choice for high-performance main inverter applications are the TC38x.

1G AURIX™ microcontroller

The AURIX™ TC3xx combines performance with a powerful safety architecture, making this family the ideal fit for automotive applications. The family concept includes scalable feature sets and pin-outs for optimal flexibility. Highlights include a multicore architecture and medium EVITA support.

Available in single or dual sensor versions with AMR or GMR technology, this XENSIV™ position sensor is automotive qualified (Q100, Grade 1: -40°C to 125°C ambient temperature) and is a green product (RoHS compliant). It offers low current consumption and quick start-up and features separate supply pins for the top and bottom sensor. Inverter design highlights include 180°(AMR) and 360°(GMR) contactless angle measurement, a high-speed analog sensor, high angular accuracy, low delay, stray field robustness and suitability for iEoS (integrated end of shaft) designs.

For more technical information, please visit our Main Inverter application page.