- ASIC

- Battery management ICs

- Clocks and timing solutions

- ESD and surge protection devices

- Automotive Ethernet

- Evaluation Boards

- High reliability

- Isolation

- Memories

- Microcontroller

- Power

- RF

- Security and smart card solutions

- Sensor technology

- Small signal transistors and diodes

- Transceivers

- Universal Serial Bus (USB)

- Wireless connectivity

- Search Tools

- Technology

- Packages

- Product Information

- Ordering

- Overview

- Automotive Ethernet Bridges

- Automotive Ethernet PHY for in-vehicle networking

- Automotive Ethernet Switches for in-vehicle networking

- Overview

- Defense

- High-reliability custom services

- NewSpace

- Space

- Overview

- Embedded flash IP solutions

- Flash+RAM MCP solutions

- F-RAM (Ferroelectric RAM)

- NOR flash

- nvSRAM (non-volatile SRAM)

- PSRAM (Pseudostatic RAM)

- Radiation hardened and high-reliability memories

- SRAM (static RAM)

- Wafer and die memory solutions

- Overview

- 32-bit FM Arm® Cortex® Microcontroller

- 32-bit AURIX™ TriCore™ microcontroller

- 32-bit PSOC™ Arm® Cortex® microcontroller

- 32-bit TRAVEO™ T2G Arm® Cortex® microcontroller

- 32-bit XMC™ industrial microcontroller Arm® Cortex®-M

- Legacy microcontroller

- Motor control SoCs/SiPs

- Sensing controllers

- Overview

- AC-DC power conversion

- Automotive conventional powertrain ICs

- Class D audio amplifier ICs

- Contactless power and sensing ICs

- DC-DC converters

- Diodes and thyristors (Si/SiC)

- Gallium nitride (GaN)

- Gate driver ICs

- IGBTs – Insulated gate bipolar transistors

- Intelligent power modules (IPM)

- LED driver ICs

- Motor drivers

- Power MOSFETs

- Power modules

- Power supply ICs

- Protection and monitoring ICs

- Silicon carbide (SiC)

- Smart power switches

- Solid state relays

- Wireless charging ICs

- Overview

- Antenna cross switches

- Antenna tuners

- Bias and control

- Coupler

- Driver amplifiers

- High Reliability Discrete

- Low noise amplifiers (LNAs)

- RF diode

- RF switches

- RF transistors

- Wireless control receiver

- Overview

- Calypso® products

- CIPURSE™ products

- Contactless memories

- OPTIGA™ embedded security solutions

- SECORA™ security solutions

- Security controllers

- Smart card modules

- Smart solutions for government ID

- Overview

- ToF 3D image sensors

- Current sensors

- Gas sensors

- Inductive position sensors

- MEMS microphones

- Pressure sensors

- Radar sensors

- Magnetic position sensors

- Magnetic speed sensors

- Overview

- Bipolar transistors

- Diodes

- Small signal/small power MOSFET

- Overview

- Automotive transceivers

- Control communication

- Powerline communications

- Overview

- USB 2.0 peripheral controllers

- USB 3.2 peripheral controllers

- USB hub controllers

- USB PD high-voltage microcontrollers

- USB-C AC-DC and DC-DC charging solutions

- USB-C charging port controllers

- USB-C Power Delivery controllers

- Overview

- AIROC™ Automotive wireless

- AIROC™ Bluetooth® and multiprotocol

- AIROC™ connected MCU

- AIROC™ Wi-Fi + Bluetooth® combos

- Overview

- Commercial off-the-shelf (COTs) memory portfolio

- Defense memory portfolio

- High-reliability power conversion and management

- Overview

- Rad hard microwave and RF

- Radiation hardened power

- Space memory portfolio

- Overview

- Parallel NOR flash

- SEMPER™ NOR flash family

- SEMPER™ X1 LPDDR flash

- Serial NOR flash

- Overview

- FM0+ 32-bit Arm® Cortex®-M0+ microcontroller (MCU) families

-

FM3 32-bit Arm® Cortex®-M3 microcontroller (MCU) families

- Overview

- FM3 CY9AFx1xK series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx1xL/M/N series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx2xK/L series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx3xK/L series ultra-low leak Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx4xL/M/N series low power Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx5xM/N/R series low power Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFxAxL/M/N series ultra-low leak Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx1xN/R high-performance series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx1xS/T high-performance series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xJ series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xK/L/M series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xS/T series Arm® Cortex®-M3 microcontroller (MCU)

-

FM4 32-bit Arm® Cortex®-M4 microcontroller (MCU) families

- Overview

- FM4 CY9BFx6xK/L high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 CY9BFx6xM/N/R high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2C high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2G series connectivity Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2H high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- Overview

-

32-bit TriCore™ AURIX™ – TC2x

- Overview

- AURIX™ family – TC21xL

- AURIX™ family – TC21xSC (wireless charging)

- AURIX™ family – TC22xL

- AURIX™ family – TC23xL

- AURIX™ family – TC23xLA (ADAS)

- AURIX™ family – TC23xLX

- AURIX™ family – TC264DA (ADAS)

- AURIX™ family – TC26xD

- AURIX™ family – TC27xT

- AURIX™ family – TC297TA (ADAS)

- AURIX™ family – TC29xT

- AURIX™ family – TC29xTT (ADAS)

- AURIX™ family – TC29xTX

- AURIX™ TC2x emulation devices

-

32-bit TriCore™ AURIX™ – TC3x

- Overview

- AURIX™ family - TC32xLP

- AURIX™ family – TC33xDA

- AURIX™ family - TC33xLP

- AURIX™ family – TC35xTA (ADAS)

- AURIX™ family – TC36xDP

- AURIX™ family – TC37xTP

- AURIX™ family – TC37xTX

- AURIX™ family – TC38xQP

- AURIX™ family – TC39xXA (ADAS)

- AURIX™ family – TC39xXX

- AURIX™ family – TC3Ex

- AURIX™ TC37xTE (emulation devices)

- AURIX™ TC39xXE (emulation devices)

- 32-bit TriCore™ AURIX™ – TC4x

- Overview

- PSOC™ 4 Arm® Cortex®-M0/M0+

- PSOC™ 4 HV Arm® Cortex®-M0+

- PSOC™ 5 LP Arm® Cortex®-M3

- PSOC™ 6 Arm® Cortex®-M4/M0+

- PSOC™ Multitouch Touchscreen Controller

- PSOC™ Control C3 Arm® Cortex®-M33

- PSOC™ Automotive 4: Arm® Cortex®-M0/M0+

- PSOC™ Edge Arm® Cortex® M55/M33

- Overview

- 32-bit TRAVEO™ T2G Arm® Cortex® for body

- 32-bit TRAVEO™ T2G Arm® Cortex® for cluster

- Overview

- 32-bit XMC1000 industrial microcontroller Arm® Cortex®-M0

- 32-bit XMC4000 industrial microcontroller Arm® Cortex®-M4

- XMC5000 Industrial Microcontroller Arm® Cortex®-M4F

- 32-bit XMC7000 Industrial Microcontroller Arm® Cortex®-M7

- Overview

- Legacy 32-bit MCU

- Legacy 8-bit/16-bit microcontroller

- Other legacy MCUs

- Overview

- AC-DC integrated power stage - CoolSET™

- AC-DC PWM-PFC controller

- Overview

- Bridge rectifiers & AC switches

- CoolSiC™ Schottky diodes

- Diode bare dies

- Silicon diodes

- Thyristor / Diode Power Modules

- Thyristor soft starter modules

- Thyristor/diode discs

- Overview

- Automotive gate driver ICs

- Isolated Gate Driver ICs

- Gate driver ICs for GaN HEMTs

- Level-Shift Gate Driver ICs

- Low-Side Drivers

- Transformer Driver ICs

- Overview

- AC-DC LED driver ICs

- Ballast IC

- DC-DC LED driver IC

- LED dimming interface IC

- Linear LED driver IC

- LITIX™ - Automotive LED Driver IC

- NFC wireless configuration IC with PWM output

- VCSEL driver

- Overview

- BLDC motor drivers

- BDC motor drivers

- Stepper & servo motor drivers

- Motor drivers with MCU

- Bridge drivers with MOSFETs

- Gate driver ICs

- Overview

- Automotive MOSFET

- Dual MOSFETs

- MOSFET (Si & SiC) Modules

- N-channel depletion mode MOSFET

- N-channel MOSFETs

- P-channel MOSFETs

- Silicon carbide CoolSiC™ MOSFETs

- Small signal/small power MOSFET

- Overview

- Automotive transceivers

- Linear Voltage Regulators for Automotive Applications

- OPTIREG™ PMIC

- OPTIREG™ switcher

- OPTIREG™ System Basis Chips (SBC)

- Overview

- eFuse

-

High-side switches

- Overview

- Classic PROFET™ 12V | Automotive smart high-side switch

- Classic PROFET™ 24V | Automotive smart high-side switch

- Power PROFET™ + 12/24/48V | Automotive smart high-side switch

- PROFET™ + 12V | Automotive smart high-side switch

- PROFET™ + 24V | Automotive smart high-side switch

- PROFET™ + 48V | Automotive smart high-side switch

- PROFET™ +2 12V | Automotive smart high-side switch

- PROFET™ Industrial | Smart high-side switch

- PROFET™ Wire Guard 12V | Automotive eFuse

- Low-side switches

- Multichannel SPI Switches & Controller

- Overview

- Radar sensors for automotive

- Radar sensors for IoT

- Overview

- EZ-USB™ CX3 MIPI CSI2 to USB 3.0 camera controller

- EZ-USB™ FX10 & FX5N USB 10Gbps peripheral controller

- EZ-USB™ FX20 USB 20 Gbps peripheral controller

- EZ-USB™ FX3 USB 5 Gbps peripheral controller

- EZ-USB™ FX3S USB 5 Gbps peripheral controller with storage interface

- EZ-USB™ FX5 USB 5 Gbps peripheral controller

- EZ-USB™ SD3 USB 5 Gbps storage controller

- EZ-USB™ SX3 FIFO to USB 5 Gbps peripheral controller

- Overview

- EZ-PD™ CCG3 USB type-C port controller PD

- EZ-PD™ CCG3PA USB-C and PD

- EZ-PD™ CCG3PA-NFET USB-C PD controller

- EZ-PD™ CCG7x consumer USB-C Power Delivery & DC-DC controller

- EZ-PD™ PAG1: power adapter generation 1

- EZ-PD™ PAG2: Power Adapter Generation 2

- EZ-PD™ PAG2-PD USB-C PD Controller

- Overview

- EZ-PD™ ACG1F one-port USB-C controller

- EZ-PD™ CCG2 USB Type-C port controller

- EZ-PD™ CCG3PA Automotive USB-C and Power Delivery controller

- EZ-PD™ CCG4 two-port USB-C and PD

- EZ-PD™ CCG5 dual-port and CCG5C single-port USB-C PD controllers

- EZ-PD™ CCG6 one-port USB-C & PD controller

- EZ-PD™ CCG6_CFP and EZ-PD™ CCG8_CFP Dual-Single-Port USB-C PD

- EZ-PD™ CCG6DF dual-port and CCG6SF single-port USB-C PD controllers

- EZ-PD™ CCG7D Automotive dual-port USB-C PD + DC-DC controller

- EZ-PD™ CCG7S Automotive single-port USB-C PD solution with a DC-DC controller + FETs

- EZ-PD™ CCG7SAF Automotive Single-port USB-C PD + DC-DC Controller + FETs

- EZ-PD™ CCG8 dual-single-port USB-C PD

- EZ-PD™ CMG1 USB-C EMCA controller

- EZ-PD™ CMG2 USB-C EMCA controller with EPR

- LATEST IN

- Aerospace and defense

- Automotive

- Consumer electronics

- Health and lifestyle

- Home appliances

- Industrial

- Information and Communication Technology

- Renewables

- Robotics

- Security solutions

- Smart home and building

- Solutions

- Overview

- Defense applications

- Space applications

- Overview

- ADAS & autonomous driving

- Automotive body electronics & power distribution

- Automotive LED lighting systems

- Chassis control & safety

- Electric vehicle drivetrain system

- EV thermal management system

- In-vehicle infotainment & HMI

- Light electric vehicle solutions

- Overview

- Power adapters and chargers

- Complete system solutions for smart TVs

- Mobile device and smartphone solutions

- Multicopters and drones

- Power tools

- Semiconductor solutions for home entertainment applications

- Smart conference systems

- Overview

- Adapters and chargers

- Asset Tracking

- Battery formation and testing

- Electric forklifts

- Battery energy storage (BESS)

- EV charging

- High voltage solid-state power distribution

- Industrial automation

- Industrial motor drives and controls

- Industrial robots system solutions for Industry 4.0

- LED lighting system design

- Light electric vehicle solutions

- Power tools

- Power transmission and distribution

- Traction

- Uninterruptible power supplies (UPS)

- Overview

- Data center and AI data center solutions

- Edge computing

- Telecommunications infrastructure

- Machine Learning Edge AI

- Overview

- Battery formation and testing

- EV charging

- Hydrogen

- Photovoltaic

- Wind power

- Solid-state circuit breaker

- Battery energy storage (BESS)

- Overview

- Device authentication and brand protection

- Embedded security for the Internet of Things (IoT)

- eSIM applications

- Government identification

- Mobile security

- Payment solutions

- Access control and ticketing

- Overview

- Domestic robots

- Heating ventilation and air conditioning (HVAC)

- Home and building automation

- PC accessories

- Semiconductor solutions for home entertainment applications

- Overview

- Battery management systems (BMS)

- Connectivity

- Human Machine Interface

- Machine Learning Edge AI

- Motor control

- Power conversion

- Security

- Sensor solutions

- System diagnostics and analytics

- Overview

- Automotive auxiliary systems

- Automotive gateway

- Automotive power distribution

- Body control modules (BCM)

- Comfort & convenience electronics

- Zonal DC-DC converter 48 V-12 V

- Zone control unit

- Overview

- Automotive animated LED lighting system

- Automotive LED front single light functions

- Automotive LED rear single light functions

- Full LED headlight system - multi-channel LED driver

- LED drivers (electric two- & three-wheelers)

- LED pixel light controller - supply & communication

- Static interior ambient LED light

- Overview

- Active suspension control

- Automotive braking solutions

- Automotive steering solutions

- Chassis domain control

- Overview

-

Automotive BMS

- Overview

- Automotive battery cell monitoring & balancing

- Automotive battery control unit (BCU)

- Automotive battery isolated communication

- Automotive battery management system (BMS) - 12 V to 24 V

- Automotive battery management system (BMS) - 48 V

- Automotive battery management system (BMS) - high-voltage

- Automotive battery pack monitoring

- Automotive battery passport & event logging

- Automotive battery protection & disconnection

- Automotive current sensing & coulomb counting

- BMS (electric two- & three-wheelers)

- EV charging

- EV inverters

- EV power conversion & OBC

- FCEV powertrain system

- Overview

- E-bike solutions

- Two- & three-wheeler solutions

- Overview

- Audio amplifier solutions

- Complete system solutions for smart TVs

- Distribution audio amplifier unit solutions

- Home theater installation speaker system solutions

- Party speaker solutions

- PoE audio amplifier unit solutions

- Portable speaker solutions

- Powered active speaker systems

- Remote control

- Smart speaker designs

- Soundbar solutions

- Overview

- Data center and AI data center solutions

- Digital input/output (I/O) modules

- DIN rail power supply solutions

- Home and building automation

- Industrial HMI Monitors and Panels

- Industrial motor drives and controls

- Industrial PC

- Industrial robots system solutions for Industry 4.0

- Machine vision

- Mobile robots (AGV, AMR)

- Programmable logic controller (PLC)

- Solid-state circuit breaker

- Uninterruptible power supplies (UPS)

- Overview

- 48 V intermediate bus converter (IBC)

- AI accelerator cards

- AMD server CPUs

- Ampere CPUs

- FPGAs in datacenter applications

- Intel server CPUs

- Networking and switch platforms

- Power path protection

- Power system reliability modeling

- RAID storage

- Server battery backup units (BBU)

- Server power supply

- SmartNIC cards

- Overview

- AC-DC power conversion for telecommunications infrastructure

- DC-DC power conversion for telecommunications infrastructure

- FPGA in wired and wireless telecommunications applications

- Satellite communications

- Power system reliability modeling

- RF front end components for telecommunications infrastructure

- Overview

-

AC-DC power conversion

- Overview

- AC-DC auxiliary power supplies

- AC-DC power conversion for telecommunications infrastructure

- Adapters and chargers

- Automotive LED lighting systems

- Complete system solutions for smart TVs

- Desktop power supplies

- EV charging

- Industrial power supplies

- PoE power sourcing equipment (PSE)

- Server power supply units (PSU)

- Uninterruptible power supplies (UPS)

- DC-DC power conversion

- Overview

- Power supply health monitoring

- LATEST IN

- Digital documentation

- Evaluation boards

- Finder & selection tools

- Platforms

- Services

- Simulation & Modeling

- Software

- Tools

- Partners

- Infineon for Makers

- University Alliance Program

- Overview

- Bipolar Discs Finder

- Bipolar Module Finder

- Connected Secure Systems Finder

- Diode Rectifier Finder

- ESD Protection Finder

- Evaluation Board Finder

- Gate Driver Finder

- IGBT Discrete Finder

- IGBT Module Finder

- IPM Finder

- Microcontroller Finder

- MOSFET Finder

- PMIC Finder

- Product Finder

- PSOC™ and FMx MCU Board & Kit Finder

- Radar Finder

- Reference Design Finder

- Simulation Model Finder

- Smart Power Switch Finder

- Transceiver Finder

- Voltage Regulator Finder

- Wireless Connectivity Board & Kit Finder

- Overview

- AIROC™ software & tools

- AURIX™ software & tools

- DRIVECORE for automotive software development

- iMOTION™ software & tools

- Infineon Smart Power Switches & Gate Driver Tool Suite

- MOTIX™ software & tools

- OPTIGA™ software & tools

- PSOC™ software & tools

- TRAVEO™ software & tools

- XENSIV™ software & tools

- XMC™ software & tools

- Overview

- CoolGaN™ Simulation Tool (PLECS)

- HiRel Fit Rate Tool

- Infineon Designer

- Interactive product sheet

- IPOSIM Online Power Simulation Platform

- InfineonSpice Offline Simulation Tool

- OPTIREG™ automotive power supply ICs Simulation Tool (PLECS)

- Power MOSFET Simulation Models

- PowerEsim Switch Mode Power Supply Design Tool

- Solution Finder

- XENSIV™ Magnetic Sensor Simulation Tool

- Overview

- AURIX™ certifications

- AURIX™ development tools

-

AURIX™ Embedded Software

- Overview

- AURIX™ Applications software

- AURIX™ Artificial Intelligence

- AURIX™ Gateway

- AURIX™ iLLD Drivers

- Infineon safety

- AURIX™ Security

- AURIX™ TC3xx Motor Control Application Kit

- AURIX™ TC4x SW application architecture

- Infineon AUTOSAR

- Communication and Connectivity

- Middleware

- Non AUTOSAR OS/RTOS

- OTA

- AURIX™ Microcontroller Kits

- Overview

- TRAVEO™ Development Tools

- TRAVEO™ Embedded Software

- Overview

- XENSIV™ Development Tools

- XENSIV™ Embedded Software

- XENSIV™ evaluation boards

- Overview

- CAPSENSE™ Controllers Code Examples

- Memories for Embedded Systems Code Examples

- PSOC™ 1 Code Examples for PSOC™ Designer

- PSOC™ 3 Code Examples for PSOC™ Creator

- PSOC™ 3/4/5 Code Examples

- PSOC™ 4 Code Examples for PSOC™ Creator

- PSOC™ 6 Code Examples for PSOC™ Creator

- PSOC™ 63 Code Examples

- USB Controllers Code Examples

- Overview

- DEEPCRAFT™ AI Hub

- DEEPCRAFT™ Audio Enhancement

- DEEPCRAFT™ Model Converter

-

DEEPCRAFT™ Ready Models

- Overview

- DEEPCRAFT™ Ready Model for Baby Cry Detection

- DEEPCRAFT™ Ready Model for Cough Detection

- DEEPCRAFT™ Ready Model for Direction of Arrival (Sound)

- DEEPCRAFT™ Ready Model for Factory Alarm Detection

- DEEPCRAFT™ Ready Model for Fall Detection

- DEEPCRAFT™ Ready Model for Gesture Classification

- DEEPCRAFT™ Ready Model for Siren Detection

- DEEPCRAFT™ Ready Model for Snore Detection

- DEEPCRAFT™ Studio

- DEEPCRAFT™ Voice Assistant

- Overview

- AIROC™ Wi-Fi & Bluetooth EZ-Serial Module Firmware Platform

- AIROC™ Wi-Fi & Bluetooth Linux and Android Drivers

- emWin Graphics Library and GUI for PSOC™

- Infineon Complex Device Driver for Battery Management Systems

- Memory Solutions Hub

- PSOC™ 6 Peripheral Driver Library (PDL) for PSOC™ Creator

- USB Controllers EZ-USB™ GX3 Software and Drivers

- Overview

- CAPSENSE™ Controllers Configuration Tools EZ-Click

- DC-DC Integrated POL Voltage Regulators Configuration Tool – PowIRCenter

- EZ-USB™ SX3 Configuration Utility

- FM+ Configuration Tools

- FMx Configuration Tools

- Tranceiver IC Configuration Tool

- USB EZ-PD™ Configuration Utility

- USB EZ-PD™ Dock Configuration Utility

- USB EZ-USB™ HX3C Blaster Plus Configuration Utility

- USB UART Config Utility

- XENSIV™ Tire Pressure Sensor Programming

- Overview

- EZ-PD™ CCGx Dock Software Development Kit

-

FMx Softune IDE

- Overview

- RealOS™ Real-Time Operating System

- Softune IDE Language tools

- Softune Workbench

- Tool Lineup for F2MC-16 Family SOFTUNE V3

- Tool Lineup for F2MC-8FX Family SOFTUNE V3

- Tool Lineup for FR Family SOFTUNE V6

- Virtual Starter Kit

- Windows 10 operation of released SOFTUNE product

- Windows 7 operation of released SOFTUNE product

- Windows 8 operation of released SOFTUNE product

- ModusToolbox™ Software

- PSOC™ Creator Software

- Radar Development Kit

- RUST

- USB Controllers SDK

- Wireless Connectivity Bluetooth Mesh Helper Applications

- XMC™ DAVE™ Software

- Overview

- AIROC™ Bluetooth® Connect App Archive

- Cypress™ Programmer Archive

- EZ-PD™ CCGx Power Software Development Kit Archive

- ModusToolbox™ Software Archive

- PSOC™ Creator Archive

- PSOC™ Designer Archive

- PSOC™ Programmer Archive

- USB EZ-PD™ Configuration Utility Archives

- USB EZ-PD™ Host SDK Archives

- USB EZ-USB™ FX3 Archive

- USB EZ-USB™ HX3PD Configuration Utility Archive

- WICED™ Smart SDK Archive

- WICED™ Studio Archive

- Overview

- Infineon Developer Center Launcher

- Infineon Register Viewer

- Pin and Code Wizard

- Timing Solutions

- Wireless Connectivity

- LATEST IN

- Support

- Training

- Developer Community

- News

Business & Financial Press

Feb 23, 2026

Business & Financial Press

Feb 19, 2026

Business & Financial Press

Feb 19, 2026

Business & Financial Press

Feb 19, 2026

- Company

- Our stories

- Events

- Press

- Investor

- Careers

- Quality

- Latest news

Business & Financial Press

Feb 23, 2026

Business & Financial Press

Feb 19, 2026

Business & Financial Press

Feb 19, 2026

Business & Financial Press

Feb 19, 2026

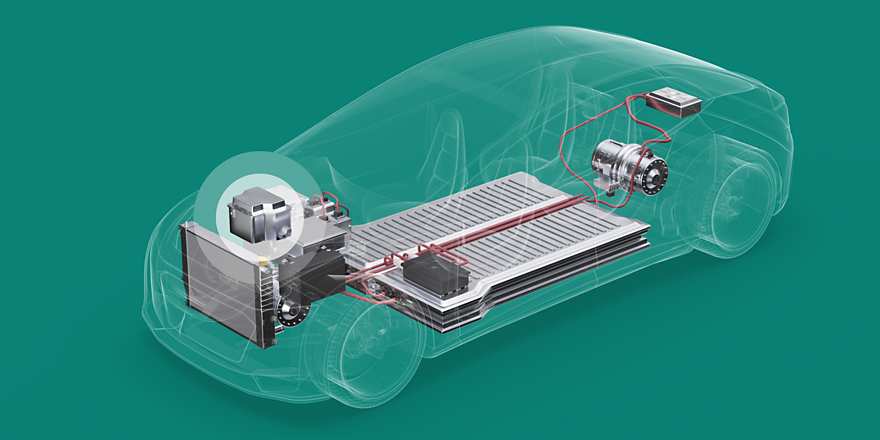

EV traction inverter

Accelerate vehicle performance with automotive-qualified and highly efficient solutions supporting a scalable range of motors and power classes

-

On this page

Overview

Enhance traction inverter designs and achieve the highest efficiency, optimized performance, and fastest time-to-market with Infineon's complete system solution. As an essential component for electric vehicle (EV) drivetrains, traction inverters control the motor and determine driving behavior. Our commitment to quality ensures minimal switching losses, maximum thermal efficiency, and enables regenerative braking to recharge the battery.

Benefits

- Complete system solution

- Fast time-to-market

- Most scalable power portfolio

- Reduce design-in effort

- Gate driver up to ASIL-D

- AURIX™ MCU: Resolver interface

Block diagram

About

Enhance vehicle performance with state-of-the-art traction inverter technology. These inverters manage motor speed and torque, enable regenerative braking, and ensure optimal power delivery. Infineon’s rigorously tested components offer high efficiency, minimal switching losses, and robust thermal management to boost system performance and extend driving range. Our scalable, automotive-qualified solutions accelerate market entry while optimizing EV performance.

Learn more about the benefits of Infineon’s EV traction inverter devices.

- Automotive-qualified portfolio for various motors, generators, and power classes.

- Highly scalable automotive power solution (frame, molded, discrete, bare die) that simplifies platform migration and reduces design work.

- Gate drivers with slew rate control for efficient performance.

- 32-bit microcontrollers with features like resolver interface and AI predictive maintenance.

- Coreless current sensor scalable for the 2nd-generation HybridPACK™ Drive™ power module.

- Evaluation kit with 30+ Infineon components to shorten development time.

SiC-based power electronics for EV inverters are advancing quickly. Under the WLTP profile, characterized by partial current loads, SiC offers about a significant 6% range gain in 800V systems compared to silicon. Both materials are expected to coexist — SiC in rear-wheel inverters for range extension and silicon in front-wheel systems for cost savings. Additionally, innovative fusion technology combining Si and SiC delivers significant cost benefits, though with a slight range reduction. Infineon leads this innovation, partnering with top automotive Tier 1 suppliers to enable the most cost-efficient EV inverters.

Evaluation kit for fast design-in, including:

- HybridPACK™ Drive CoolSiC™ G2, sintered, ceramic, direct cooling and on-chip temperature sensing

- Gate driver board with EiceDRIVER™ G3

- Logic board with AURIX™ MCU

- Communication and development interface: CAN, USB, DAP

- Software supports flexible operational modes

- One-eye GUI interface enabling full customization

- Current sensor vertically integrated into the busbar for optimized space and cost

- Aluminum cooler in reference design, plastic cooler as optional

- DC link capacitor

Enhance vehicle performance with state-of-the-art traction inverter technology. These inverters manage motor speed and torque, enable regenerative braking, and ensure optimal power delivery. Infineon’s rigorously tested components offer high efficiency, minimal switching losses, and robust thermal management to boost system performance and extend driving range. Our scalable, automotive-qualified solutions accelerate market entry while optimizing EV performance.

Learn more about the benefits of Infineon’s EV traction inverter devices.

- Automotive-qualified portfolio for various motors, generators, and power classes.

- Highly scalable automotive power solution (frame, molded, discrete, bare die) that simplifies platform migration and reduces design work.

- Gate drivers with slew rate control for efficient performance.

- 32-bit microcontrollers with features like resolver interface and AI predictive maintenance.

- Coreless current sensor scalable for the 2nd-generation HybridPACK™ Drive™ power module.

- Evaluation kit with 30+ Infineon components to shorten development time.

SiC-based power electronics for EV inverters are advancing quickly. Under the WLTP profile, characterized by partial current loads, SiC offers about a significant 6% range gain in 800V systems compared to silicon. Both materials are expected to coexist — SiC in rear-wheel inverters for range extension and silicon in front-wheel systems for cost savings. Additionally, innovative fusion technology combining Si and SiC delivers significant cost benefits, though with a slight range reduction. Infineon leads this innovation, partnering with top automotive Tier 1 suppliers to enable the most cost-efficient EV inverters.

Evaluation kit for fast design-in, including:

- HybridPACK™ Drive CoolSiC™ G2, sintered, ceramic, direct cooling and on-chip temperature sensing

- Gate driver board with EiceDRIVER™ G3

- Logic board with AURIX™ MCU

- Communication and development interface: CAN, USB, DAP

- Software supports flexible operational modes

- One-eye GUI interface enabling full customization

- Current sensor vertically integrated into the busbar for optimized space and cost

- Aluminum cooler in reference design, plastic cooler as optional

- DC link capacitor