iMOTION™ Integrated Power Module (IPM) Fully integrated power modules for BLDC motor control

Motor controller IC and a three-phase inverter stage in a single package

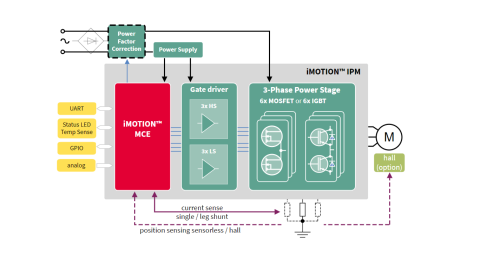

IPM is a family of fully integrated modules for the control of three-phase motors, optimized for low-power devices. Within the iMOTION™ IPM family, there are two different series: The IMM100 and IMI110, which combine the motor controller IC and a three-phase inverter stage in a single package, minimizing external components count and PCB area. The three-phase inverter stage is based either on six MOSFETs or six IGBTs. These iMOTION™ IPMs offer the highest integration level by making use of the field-proven iMOTION™.

Motion Control Engine (MCE) in combination with providing all required hardware functions: From single shunt current sensing to bootstrap capability, signal filtering and several hardware protections like dead-time insertion and shoot through prevention. An iMOTION™ IPM does not require a heatsink and addresses motor drives with a typical application input power between 70 W and 80W with 600 V maximum DC blocking voltage, depending on the chosen product variant.

All IMI110 and IMM100 devices support the functional safety requirements according to the IEC/UL 60730 ("class B").

Our Developer Community is available 24x7 for you to connect and network with engineers across the globe. Get help from our support engineers, and expert members to solve your design challenges anytime, from anywhere, in any topic, and in your preferred language.

iMOTION™ IPM

The block diagram illustrates the various options that the IPM family has to offer. The table of IMM100 and IMI110 Series, which combine the motor controller IC and a three-phase inverter stage in a single package, minimizing external components count and PCB area. The three-phase inverter stage is based either on six MOSFETs or on six IGBTs.

| IMI110 Series | IMM100 Series |

| Single shunts Sensorless - Typical application input power of ~70 W w/o heatsink HV outer pin clearance 1.3 mm DSO=-22 package IGBT switches 2 options: 2 A/600 V or 4 A/600 V

|

Single or three leg shunts Hall sensor or sensorless PFC Control Typical application input power of ~80 W w/o heatsink HV outer pin clearance 2.2 mm PQFN12x12 MOSFET 3 options: 600 V/1.4 Ω, 500 V/6 Ω, 600 V/0.95 Ω |

iMOTION™ IMI110 Series

The IMI110 series is integrating motor controller, three phase gate driver and 600 V/2 A IGBTs in a DSO-22 package.

| Features | Benefits | Applications |

| Controller, gate driver and power stage in one package Typical application input power of 70 W without heatsink DSO-22 package with single layer layout option Completely self-sustaining Motion Control Engine Support for IEC/UL 60730 ("class B") |

Unique combination of ready-2-use motor algorithms with market leading gate driver Reduced System Cost by reduced BOM count and PCB size Hall sensor based startup and sensorless high speed operation Fastest time to market by using iMOTION™ design kits No software development required No inverter hardware design needed Easy motor parametrization and tuning |

iMOTION™ IMM100 Series

The IMM100 series is the next generation of the highly-successful iMOTION™ motor control product line. It combines the motor controller IC and a 3-phase inverter stage in a single, highly compact 12 x 12 mm PQFN package.

| Features | Benefits | Applications |

| Motor Control Algorithm (FOC, sensorless or hall) Scripting engine Boost PFC control Dead time insertion & shoot-through prevention Over current / over voltage / under voltage lockout Single shunt, leg shunt, sensorless or Hall-sensor based operation Integrated power stage MOSFETs (600 V/1.4 Ω, 500 V/6 Ω, 600 V/0.95 Ω) Typical application input power of 30 W / 50 / 80 W (no heatsink) |

Full hardware and software integration for BLDC motor drives with typical application input power of 80 W Lower system cost by reducing BOM count and PCB size High-end sensorless FOC solution PFC control option IEC/UL 60730 ("class B") pre-certified software Smallest footprint for space constraint applications Reduced R&D cost and time-to-marke |

Fans for air conditioner and kitchen hood |

Find out what iMOTION™ Solution Designer offers you, how projects are created and the work flow in terms of configuration, tuning, dashboards and scripting. The tool guides you through the complete project workflow, achieving the shortest time to market with the lowest R&D efforts.

Infineon offers different solutions for low noise, small, and energy-efficient aircon fan units.

In this training you will get an overview of Infineon's iMOTION™ and CIPOS™ IPMs for both indoor and outdoor unit fans.

The latest software release of Infineon’s iMOTION™ Motion Control Engine (or MCE) supports two kinds of Universal Asynchronous Receiver Transmitter communication options. This training focuses on the Configurable UART communication protocol.

The iMOTION™ Solution Designer bundles all PC-based support functions related to setting up and running iMOTION™ products. This includes the configuration, programming and live tuning using configurable oscilloscopes as well as script editing and debugging. This training will help you get started with iMOTION™ Solution Designer.

Infineon's iMOTION™ family provides active power factor correction integrated digital motor control solutions for different product platforms, including iMOTION™ controllers, iMOTION™ drivers, and iMOTION™ IPMs.

The release of iMOTION™ 2.0 comes at an opportune time. Recent trends in the markets show that inverterization is taking hold at small as well as large companies, being applied across traditional applications, such as refrigerators, and for newer applications like hair dryers and water purifiers. To keep up with the trend, companies are required to convert outdated single speed motors to sophisticated variable speed motor drives. The latest iMOTION™ 2.0 is a close-knit turnkey solution consisting of advanced software, hardware, prototyping & evaluation boards, and support material that makes it easier than ever for customers to go to market cheaper and faster with an efficient, inverterized motor drive solution. Watch this video to get an overview of what is new with iMOTION™ 2.0. Keywords: Inverterization of motor drives

Learn more about the iMOTION™ IPM IMI110 series which is a highly integrated, feature-optimized motor control solution to easily design-in and with a ready-2-use Software, the iMOTION™ solution designer.