- ASIC

- Battery management ICs

- Clocks and timing solutions

- ESD and surge protection devices

- Automotive Ethernet

- Evaluation Boards

- High reliability

- Isolation

- Memories

- Microcontroller

- Power

- RF

- Security and smart card solutions

- Sensor technology

- Small signal transistors and diodes

- Transceivers

- Universal Serial Bus (USB)

- Wireless connectivity

- Search Tools

- Technology

- Packages

- Product Information

- Ordering

- Overview

- Automotive Ethernet Bridges

- Automotive Ethernet PHY for in-vehicle networking

- Automotive Ethernet Switches for in-vehicle networking

- Overview

- Defense

- High-reliability custom services

- NewSpace

- Space

- Overview

- Embedded flash IP solutions

- Flash+RAM MCP solutions

- F-RAM (Ferroelectric RAM)

- NOR flash

- nvSRAM (non-volatile SRAM)

- PSRAM (Pseudostatic RAM)

- Radiation hardened and high-reliability memories

- SRAM (static RAM)

- Wafer and die memory solutions

- Overview

- 32-bit FM Arm® Cortex® Microcontroller

- 32-bit AURIX™ TriCore™ microcontroller

- 32-bit PSOC™ Arm® Cortex® microcontroller

- 32-bit TRAVEO™ T2G Arm® Cortex® microcontroller

- 32-bit XMC™ industrial microcontroller Arm® Cortex®-M

- Legacy microcontroller

- Motor control SoCs/SiPs

- Sensing controllers

- Overview

- AC-DC power conversion

- Automotive conventional powertrain ICs

- Class D audio amplifier ICs

- Contactless power and sensing ICs

- DC-DC converters

- Diodes and thyristors (Si/SiC)

- Gallium nitride (GaN)

- Gate driver ICs

- IGBTs – Insulated gate bipolar transistors

- Intelligent power modules (IPM)

- LED driver ICs

- Motor drivers

- Power MOSFETs

- Power modules

- Power supply ICs

- Protection and monitoring ICs

- Silicon carbide (SiC)

- Smart power switches

- Solid state relays

- Wireless charging ICs

- Overview

- Antenna cross switches

- Antenna tuners

- Bias and control

- Coupler

- Driver amplifiers

- High Reliability Discrete

- Low noise amplifiers (LNAs)

- RF diode

- RF switches

- RF transistors

- Wireless control receiver

- Overview

- Calypso® products

- CIPURSE™ products

- Contactless memories

- OPTIGA™ embedded security solutions

- SECORA™ security solutions

- Security controllers

- Smart card modules

- Smart solutions for government ID

- Overview

- ToF 3D image sensors

- Current sensors

- Gas sensors

- Inductive position sensors

- MEMS microphones

- Pressure sensors

- Radar sensors

- Magnetic position sensors

- Magnetic speed sensors

- Overview

- Bipolar transistors

- Diodes

- Small signal/small power MOSFET

- Overview

- Automotive transceivers

- Control communication

- Powerline communications

- Overview

- USB 2.0 peripheral controllers

- USB 3.2 peripheral controllers

- USB hub controllers

- USB PD high-voltage microcontrollers

- USB-C AC-DC and DC-DC charging solutions

- USB-C charging port controllers

- USB-C Power Delivery controllers

- Overview

- AIROC™ Automotive wireless

- AIROC™ Bluetooth® and multiprotocol

- AIROC™ connected MCU

- AIROC™ Wi-Fi + Bluetooth® combos

- Overview

- Commercial off-the-shelf (COTs) memory portfolio

- Defense memory portfolio

- High-reliability power conversion and management

- Overview

- Rad hard microwave and RF

- Radiation hardened power

- Space memory portfolio

- Overview

- Parallel NOR flash

- SEMPER™ NOR flash family

- SEMPER™ X1 LPDDR flash

- Serial NOR flash

- Overview

- FM0+ 32-bit Arm® Cortex®-M0+ microcontroller (MCU) families

-

FM3 32-bit Arm® Cortex®-M3 microcontroller (MCU) families

- Overview

- FM3 CY9AFx1xK series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx1xL/M/N series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx2xK/L series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx3xK/L series ultra-low leak Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx4xL/M/N series low power Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFx5xM/N/R series low power Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9AFxAxL/M/N series ultra-low leak Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx1xN/R high-performance series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx1xS/T high-performance series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xJ series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xK/L/M series Arm® Cortex®-M3 microcontroller (MCU)

- FM3 CY9BFx2xS/T series Arm® Cortex®-M3 microcontroller (MCU)

-

FM4 32-bit Arm® Cortex®-M4 microcontroller (MCU) families

- Overview

- FM4 CY9BFx6xK/L high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 CY9BFx6xM/N/R high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2C high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2G series connectivity Arm® Cortex®-M4F microcontroller (MCU)

- FM4 S6E2H high-performance series Arm® Cortex®-M4F microcontroller (MCU)

- Overview

-

32-bit TriCore™ AURIX™ – TC2x

- Overview

- AURIX™ family – TC21xL

- AURIX™ family – TC21xSC (wireless charging)

- AURIX™ family – TC22xL

- AURIX™ family – TC23xL

- AURIX™ family – TC23xLA (ADAS)

- AURIX™ family – TC23xLX

- AURIX™ family – TC264DA (ADAS)

- AURIX™ family – TC26xD

- AURIX™ family – TC27xT

- AURIX™ family – TC297TA (ADAS)

- AURIX™ family – TC29xT

- AURIX™ family – TC29xTT (ADAS)

- AURIX™ family – TC29xTX

- AURIX™ TC2x emulation devices

-

32-bit TriCore™ AURIX™ – TC3x

- Overview

- AURIX™ family - TC32xLP

- AURIX™ family – TC33xDA

- AURIX™ family - TC33xLP

- AURIX™ family – TC35xTA (ADAS)

- AURIX™ family – TC36xDP

- AURIX™ family – TC37xTP

- AURIX™ family – TC37xTX

- AURIX™ family – TC38xQP

- AURIX™ family – TC39xXA (ADAS)

- AURIX™ family – TC39xXX

- AURIX™ family – TC3Ex

- AURIX™ TC37xTE (emulation devices)

- AURIX™ TC39xXE (emulation devices)

- 32-bit TriCore™ AURIX™ – TC4x

- Overview

- PSOC™ 4 Arm® Cortex®-M0/M0+

- PSOC™ 4 HV Arm® Cortex®-M0+

- PSOC™ 5 LP Arm® Cortex®-M3

- PSOC™ 6 Arm® Cortex®-M4/M0+

- PSOC™ Multitouch Arm® Cortex®-M0

- PSOC™ Control Arm® Cortex®-M33

- PSOC™ Automotive 4: Arm® Cortex®-M0/M0+

- PSOC™ Edge Arm® Cortex® M55/M33

- Overview

- 32-bit TRAVEO™ T2G Arm® Cortex® for body

- 32-bit TRAVEO™ T2G Arm® Cortex® for cluster

- Overview

- 32-bit XMC1000 industrial microcontroller Arm® Cortex®-M0

- 32-bit XMC4000 industrial microcontroller Arm® Cortex®-M4

- XMC5000 Industrial Microcontroller Arm® Cortex®-M4F

- 32-bit XMC7000 Industrial Microcontroller Arm® Cortex®-M7

- Overview

- Legacy 32-bit MCU

- Legacy 8-bit/16-bit microcontroller

- Other legacy MCUs

- Overview

- AC-DC integrated power stage - CoolSET™

- AC-DC PWM-PFC controller

- Overview

- Bridge rectifiers & AC switches

- CoolSiC™ Schottky diodes

- Diode bare dies

- Silicon diodes

- Thyristor / Diode Power Modules

- Thyristor soft starter modules

- Thyristor/diode discs

- Overview

- Automotive gate driver ICs

- Isolated Gate Driver ICs

- Gate driver ICs for GaN HEMTs

- Level-Shift Gate Driver ICs

- Low-Side Drivers

- Transformer Driver ICs

- Overview

- AC-DC LED driver ICs

- Ballast IC

- DC-DC LED driver IC

- LED dimming interface IC

- Linear LED driver IC

- LITIX™ - Automotive LED Driver IC

- NFC wireless configuration IC with PWM output

- VCSEL driver

- Overview

- BLDC motor drivers

- BDC motor drivers

- Stepper & servo motor drivers

- Motor drivers with MCU

- Bridge drivers with MOSFETs

- Gate driver ICs

- Overview

- Automotive MOSFET

- Dual MOSFETs

- MOSFET (Si & SiC) Modules

- N-channel depletion mode MOSFET

- N-channel MOSFETs

- P-channel MOSFETs

- Silicon carbide CoolSiC™ MOSFETs

- Small signal/small power MOSFET

- Overview

- Automotive transceivers

- Linear Voltage Regulators for Automotive Applications

- OPTIREG™ PMIC

- OPTIREG™ switcher

- OPTIREG™ System Basis Chips (SBC)

- Overview

- eFuse

-

High-side switches

- Overview

- Classic PROFET™ 12V | Automotive smart high-side switch

- Classic PROFET™ 24V | Automotive smart high-side switch

- Power PROFET™ + 12/24/48V | Automotive smart high-side switch

- PROFET™ + 12V | Automotive smart high-side switch

- PROFET™ + 24V | Automotive smart high-side switch

- PROFET™ + 48V | Automotive smart high-side switch

- PROFET™ +2 12V | Automotive smart high-side switch

- PROFET™ Industrial | Smart high-side switch

- PROFET™ Wire Guard 12V | Automotive eFuse

- Low-side switches

- Multichannel SPI Switches & Controller

- Overview

- Radar sensors for automotive

- Radar sensors for IoT

- Overview

- EZ-USB™ CX3 MIPI CSI2 to USB 3.0 camera controller

- EZ-USB™ FX10 & FX5N USB 10Gbps peripheral controller

- EZ-USB™ FX20 USB 20 Gbps peripheral controller

- EZ-USB™ FX3 USB 5 Gbps peripheral controller

- EZ-USB™ FX3S USB 5 Gbps peripheral controller with storage interface

- EZ-USB™ FX5 USB 5 Gbps peripheral controller

- EZ-USB™ SD3 USB 5 Gbps storage controller

- EZ-USB™ SX3 FIFO to USB 5 Gbps peripheral controller

- Overview

- EZ-PD™ CCG3 USB type-C port controller PD

- EZ-PD™ CCG3PA USB-C and PD

- EZ-PD™ CCG3PA-NFET USB-C PD controller

- EZ-PD™ CCG7x consumer USB-C Power Delivery & DC-DC controller

- EZ-PD™ PAG1: power adapter generation 1

- EZ-PD™ PAG2: Power Adapter Generation 2

- EZ-PD™ PAG2-PD USB-C PD Controller

- Overview

- EZ-PD™ ACG1F one-port USB-C controller

- EZ-PD™ CCG2 USB Type-C port controller

- EZ-PD™ CCG3PA Automotive USB-C and Power Delivery controller

- EZ-PD™ CCG4 two-port USB-C and PD

- EZ-PD™ CCG5 dual-port and CCG5C single-port USB-C PD controllers

- EZ-PD™ CCG6 one-port USB-C & PD controller

- EZ-PD™ CCG6_CFP and EZ-PD™ CCG8_CFP Dual-Single-Port USB-C PD

- EZ-PD™ CCG6DF dual-port and CCG6SF single-port USB-C PD controllers

- EZ-PD™ CCG7D Automotive dual-port USB-C PD + DC-DC controller

- EZ-PD™ CCG7S Automotive single-port USB-C PD solution with a DC-DC controller + FETs

- EZ-PD™ CCG7SAF Automotive Single-port USB-C PD + DC-DC Controller + FETs

- EZ-PD™ CCG8 dual-single-port USB-C PD

- EZ-PD™ CMG1 USB-C EMCA controller

- EZ-PD™ CMG2 USB-C EMCA controller with EPR

- LATEST IN

- Aerospace and defense

- Automotive

- Consumer electronics

- Health and lifestyle

- Home appliances

- Industrial

- Information and Communication Technology

- Renewables

- Robotics

- Security solutions

- Smart home and building

- Solutions

- Overview

- Defense applications

- Space applications

- Overview

- 48 V systems for EVs & mild hybrids

- ADAS & autonomous driving

- Automotive body electronics & power distribution

- Automotive LED lighting systems

- Chassis control & safety

- Electric vehicle drivetrain system

- EV thermal management system

- Internal combustion drivetrain systems

- In-vehicle infotainment & HMI

- Light electric vehicle solutions

- Overview

- Power adapters and chargers

- Complete system solutions for smart TVs

- Mobile device and smartphone solutions

- Multicopters and drones

- Power tools

- Semiconductor solutions for home entertainment applications

- Smart conference systems

- Overview

- Adapters and chargers

- Asset Tracking

- Battery formation and testing

- Electric forklifts

- Battery energy storage (BESS)

- EV charging

- High voltage solid-state power distribution

- Industrial automation

- Industrial motor drives and controls

- Industrial robots system solutions for Industry 4.0

- LED lighting system design

- Light electric vehicle solutions

- Power tools

- Power transmission and distribution

- Traction

- Uninterruptible power supplies (UPS)

- Overview

- Data center and AI data center solutions

- Edge computing

- Telecommunications infrastructure

- Machine Learning Edge AI

- Overview

- Battery formation and testing

- EV charging

- Hydrogen

- Photovoltaic

- Wind power

- Solid-state circuit breaker

- Battery energy storage (BESS)

- Overview

- Device authentication and brand protection

- Embedded security for the Internet of Things (IoT)

- eSIM applications

- Government identification

- Mobile security

- Payment solutions

- Access control and ticketing

- Overview

- Domestic robots

- Heating ventilation and air conditioning (HVAC)

- Home and building automation

- PC accessories

- Semiconductor solutions for home entertainment applications

- Overview

- Battery management systems (BMS)

- Connectivity

- Human Machine Interface

- Machine Learning Edge AI

- Motor control

- Power conversion

- Security

- Sensor solutions

- System diagnostics and analytics

- Overview

- Automotive auxiliary systems

- Automotive gateway

- Automotive power distribution

- Body control modules (BCM)

- Comfort & convenience electronics

- Zonal DC-DC converter 48 V-12 V

- Zone control unit

- Overview

- Automotive animated LED lighting system

- Automotive LED front single light functions

- Automotive LED rear single light functions

- Full LED headlight system - multi-channel LED driver

- LED drivers (electric two- & three-wheelers)

- LED pixel light controller - supply & communication

- Static interior ambient LED light

- Overview

- Active suspension control

- Airbag system

- Automotive braking solutions

- Automotive steering solutions

- Chassis domain control

- Reversible seatbelt pretensioner

- Overview

-

Automotive BMS

- Overview

- Automotive battery cell monitoring & balancing

- Automotive battery control unit (BCU)

- Automotive battery isolated communication

- Automotive battery management system (BMS) - 12 V to 24 V

- Automotive battery management system (BMS) - 48 V

- Automotive battery management system (BMS) - high-voltage

- Automotive battery pack monitoring

- Automotive battery passport & event logging

- Automotive battery protection & disconnection

- Automotive current sensing & coulomb counting

- BMS (electric two- & three-wheelers)

- EV charging

- EV inverters

- EV power conversion & OBC

- FCEV powertrain system

- Overview

- Automatic transmission hydraulic system

- Belt starter generator 48 V – inverter ISG

- Diesel direct injection

- Double-clutch transmission electrical control

- Double-clutch transmission hydraulic control

- Gasoline direct injection

- Multi-port fuel injection

- Small 1-cylinder combustion engine solution

- Small engine starter kit

- Transfer case brushed DC

- Transfer case brushless DC (BLDC)

- Overview

- Automotive head unit

- Automotive USB-C power & data solution

- Automotive instrument cluster

- Automotive telematics control unit (TCU)

- Center information display (CID)

- High-performance cockpit controller

- In-cabin wireless charging

- Smart instrument cluster (electric two- & three-wheelers)

- Overview

- E-bike solutions

- Two- & three-wheeler solutions

- Overview

- Audio amplifier solutions

- Complete system solutions for smart TVs

- Distribution audio amplifier unit solutions

- Home theater installation speaker system solutions

- Party speaker solutions

- PoE audio amplifier unit solutions

- Portable speaker solutions

- Powered active speaker systems

- Remote control

- Smart speaker designs

- Soundbar solutions

- Overview

- Data center and AI data center solutions

- Digital input/output (I/O) modules

- DIN rail power supply solutions

- Home and building automation

- Industrial HMI Monitors and Panels

- Industrial motor drives and controls

- Industrial PC

- Industrial robots system solutions for Industry 4.0

- Machine vision

- Mobile robots (AGV, AMR)

- Programmable logic controller (PLC)

- Solid-state circuit breaker

- Uninterruptible power supplies (UPS)

- Overview

- 48 V intermediate bus converter (IBC)

- AI accelerator cards

- AMD server CPUs

- Ampere CPUs

- FPGAs in datacenter applications

- Intel server CPUs

- Networking and switch platforms

- Power path protection

- Power system reliability modeling

- RAID storage

- Server battery backup units (BBU)

- Server power supply

- SmartNIC cards

- Overview

- AC-DC power conversion for telecommunications infrastructure

- DC-DC power conversion for telecommunications infrastructure

- FPGA in wired and wireless telecommunications applications

- Satellite communications

- Power system reliability modeling

- RF front end components for telecommunications infrastructure

- Overview

-

AC-DC power conversion

- Overview

- AC-DC auxiliary power supplies

- AC-DC power conversion for telecommunications infrastructure

- Adapters and chargers

- Automotive LED lighting systems

- Complete system solutions for smart TVs

- Desktop power supplies

- EV charging

- Industrial power supplies

- PoE power sourcing equipment (PSE)

- Server power supply units (PSU)

- Uninterruptible power supplies (UPS)

- DC-DC power conversion

- Overview

- Power supply health monitoring

- LATEST IN

- Digital documentation

- Evaluation boards

- Finder & selection tools

- Platforms

- Services

- Simulation & Modeling

- Software

- Tools

- Partners

- Infineon for Makers

- University Alliance Program

- Overview

- Bipolar Discs Finder

- Bipolar Module Finder

- Connected Secure Systems Finder

- Diode Rectifier Finder

- ESD Protection Finder

- Evaluation Board Finder

- Gate Driver Finder

- IGBT Discrete Finder

- IGBT Module Finder

- IPM Finder

- Microcontroller Finder

- MOSFET Finder

- PMIC Finder

- Product Finder

- PSOC™ and FMx MCU Board & Kit Finder

- Radar Finder

- Reference Design Finder

- Simulation Model Finder

- Smart Power Switch Finder

- Transceiver Finder

- Voltage Regulator Finder

- Wireless Connectivity Board & Kit Finder

- Overview

- AIROC™ software & tools

- AURIX™ software & tools

- DRIVECORE for automotive software development

- iMOTION™ software & tools

- Infineon Smart Power Switches & Gate Driver Tool Suite

- MOTIX™ software & tools

- OPTIGA™ software & tools

- PSOC™ software & tools

- TRAVEO™ software & tools

- XENSIV™ software & tools

- XMC™ software & tools

- Overview

- CoolGaN™ Simulation Tool (PLECS)

- HiRel Fit Rate Tool

- Infineon Designer

- Interactive product sheet

- IPOSIM Online Power Simulation Platform

- InfineonSpice Offline Simulation Tool

- OPTIREG™ automotive power supply ICs Simulation Tool (PLECS)

- Power MOSFET Simulation Models

- PowerEsim Switch Mode Power Supply Design Tool

- Solution Finder

- XENSIV™ Magnetic Sensor Simulation Tool

- Overview

- AURIX™ certifications

- AURIX™ development tools

-

AURIX™ Embedded Software

- Overview

- AURIX™ Applications software

- AURIX™ Artificial Intelligence

- AURIX™ Gateway

- AURIX™ iLLD Drivers

- Infineon safety

- AURIX™ Security

- AURIX™ TC3xx Motor Control Application Kit

- AURIX™ TC4x SW application architecture

- Infineon AUTOSAR

- Communication and Connectivity

- Middleware

- Non AUTOSAR OS/RTOS

- OTA

- AURIX™ Microcontroller Kits

- Overview

- TRAVEO™ Development Tools

- TRAVEO™ Embedded Software

- Overview

- XENSIV™ Development Tools

- XENSIV™ Embedded Software

- XENSIV™ evaluation boards

- Overview

- CAPSENSE™ Controllers Code Examples

- Memories for Embedded Systems Code Examples

- PSOC™ 1 Code Examples for PSOC™ Designer

- PSOC™ 3 Code Examples for PSOC™ Creator

- PSOC™ 3/4/5 Code Examples

- PSOC™ 4 Code Examples for PSOC™ Creator

- PSOC™ 6 Code Examples for PSOC™ Creator

- PSOC™ 63 Code Examples

- USB Controllers Code Examples

- Overview

- DEEPCRAFT™ AI Hub

- DEEPCRAFT™ Audio Enhancement

- DEEPCRAFT™ Model Converter

-

DEEPCRAFT™ Ready Models

- Overview

- DEEPCRAFT™ Ready Model for Baby Cry Detection

- DEEPCRAFT™ Ready Model for Cough Detection

- DEEPCRAFT™ Ready Model for Direction of Arrival (Sound)

- DEEPCRAFT™ Ready Model for Factory Alarm Detection

- DEEPCRAFT™ Ready Model for Fall Detection

- DEEPCRAFT™ Ready Model for Gesture Classification

- DEEPCRAFT™ Ready Model for Siren Detection

- DEEPCRAFT™ Ready Model for Snore Detection

- DEEPCRAFT™ Studio

- DEEPCRAFT™ Voice Assistant

- Overview

- AIROC™ Wi-Fi & Bluetooth EZ-Serial Module Firmware Platform

- AIROC™ Wi-Fi & Bluetooth Linux and Android Drivers

- emWin Graphics Library and GUI for PSOC™

- Infineon Complex Device Driver for Battery Management Systems

- Memory Solutions Hub

- PSOC™ 6 Peripheral Driver Library (PDL) for PSOC™ Creator

- USB Controllers EZ-USB™ GX3 Software and Drivers

- Overview

- CAPSENSE™ Controllers Configuration Tools EZ-Click

- DC-DC Integrated POL Voltage Regulators Configuration Tool – PowIRCenter

- EZ-USB™ SX3 Configuration Utility

- FM+ Configuration Tools

- FMx Configuration Tools

- Tranceiver IC Configuration Tool

- USB EZ-PD™ Configuration Utility

- USB EZ-PD™ Dock Configuration Utility

- USB EZ-USB™ HX3C Blaster Plus Configuration Utility

- USB UART Config Utility

- XENSIV™ Tire Pressure Sensor Programming

- Overview

- EZ-PD™ CCGx Dock Software Development Kit

-

FMx Softune IDE

- Overview

- RealOS™ Real-Time Operating System

- Softune IDE Language tools

- Softune Workbench

- Tool Lineup for F2MC-16 Family SOFTUNE V3

- Tool Lineup for F2MC-8FX Family SOFTUNE V3

- Tool Lineup for FR Family SOFTUNE V6

- Virtual Starter Kit

- Windows 10 operation of released SOFTUNE product

- Windows 7 operation of released SOFTUNE product

- Windows 8 operation of released SOFTUNE product

- ModusToolbox™ Software

- PSOC™ Creator Software

- Radar Development Kit

- RUST

- USB Controllers SDK

- Wireless Connectivity Bluetooth Mesh Helper Applications

- XMC™ DAVE™ Software

- Overview

- AIROC™ Bluetooth® Connect App Archive

- Cypress™ Programmer Archive

- EZ-PD™ CCGx Power Software Development Kit Archive

- ModusToolbox™ Software Archive

- PSOC™ Creator Archive

- PSOC™ Designer Archive

- PSOC™ Programmer Archive

- USB EZ-PD™ Configuration Utility Archives

- USB EZ-PD™ Host SDK Archives

- USB EZ-USB™ FX3 Archive

- USB EZ-USB™ HX3PD Configuration Utility Archive

- WICED™ Smart SDK Archive

- WICED™ Studio Archive

- Overview

- Infineon Developer Center Launcher

- Infineon Register Viewer

- Pin and Code Wizard

- Timing Solutions

- Wireless Connectivity

- LATEST IN

- Support

- Training

- Developer Community

- News

Business & Financial Press

Feb 16, 2026

Business & Financial Press

Feb 10, 2026

Business & Financial Press

Feb 04, 2026

Quarterly Report

Feb 04, 2026

- Company

- Our stories

- Events

- Press

- Investor

- Careers

- Quality

- Latest news

Business & Financial Press

Feb 16, 2026

Business & Financial Press

Feb 10, 2026

Business & Financial Press

Feb 04, 2026

Quarterly Report

Feb 04, 2026

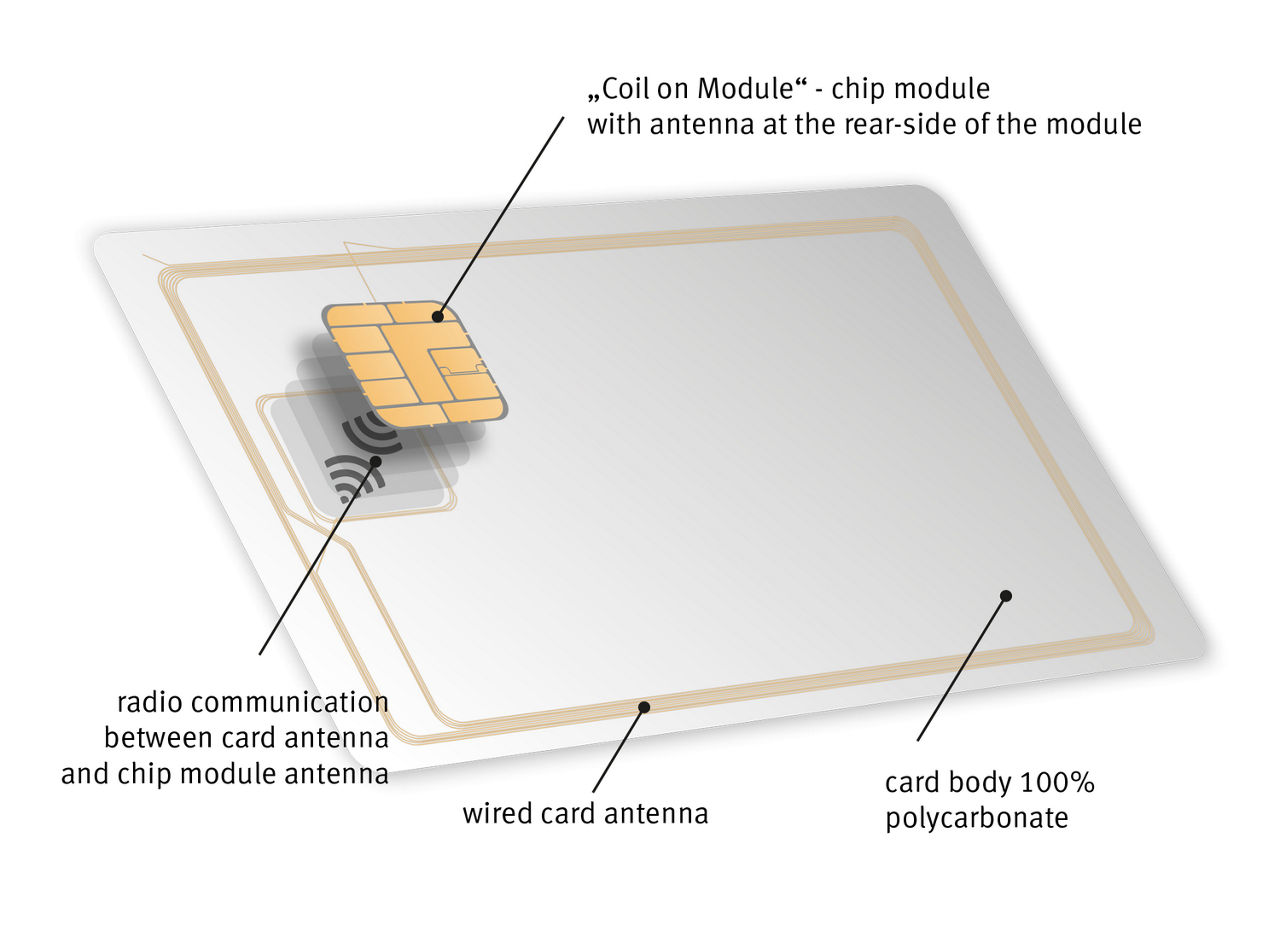

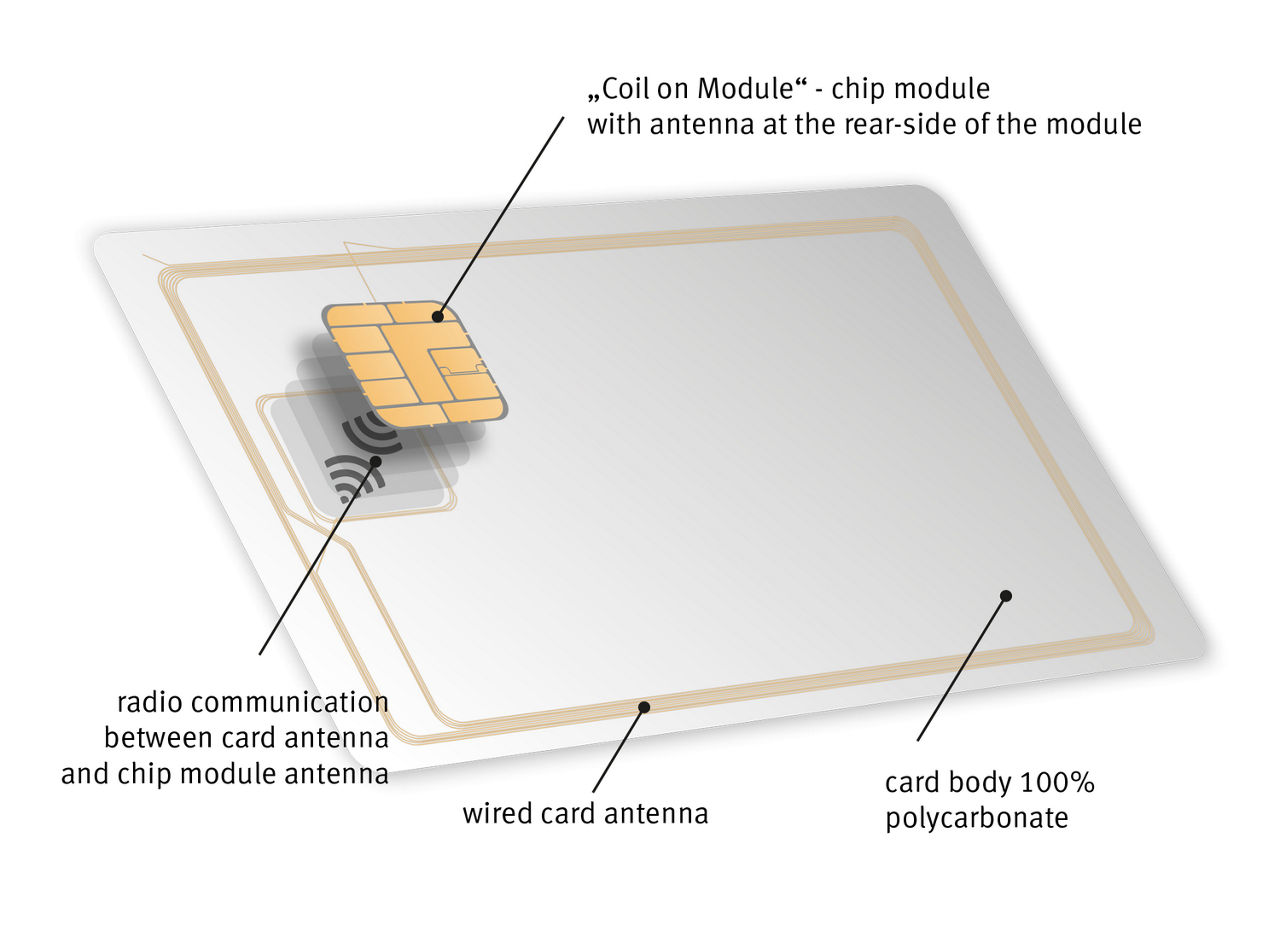

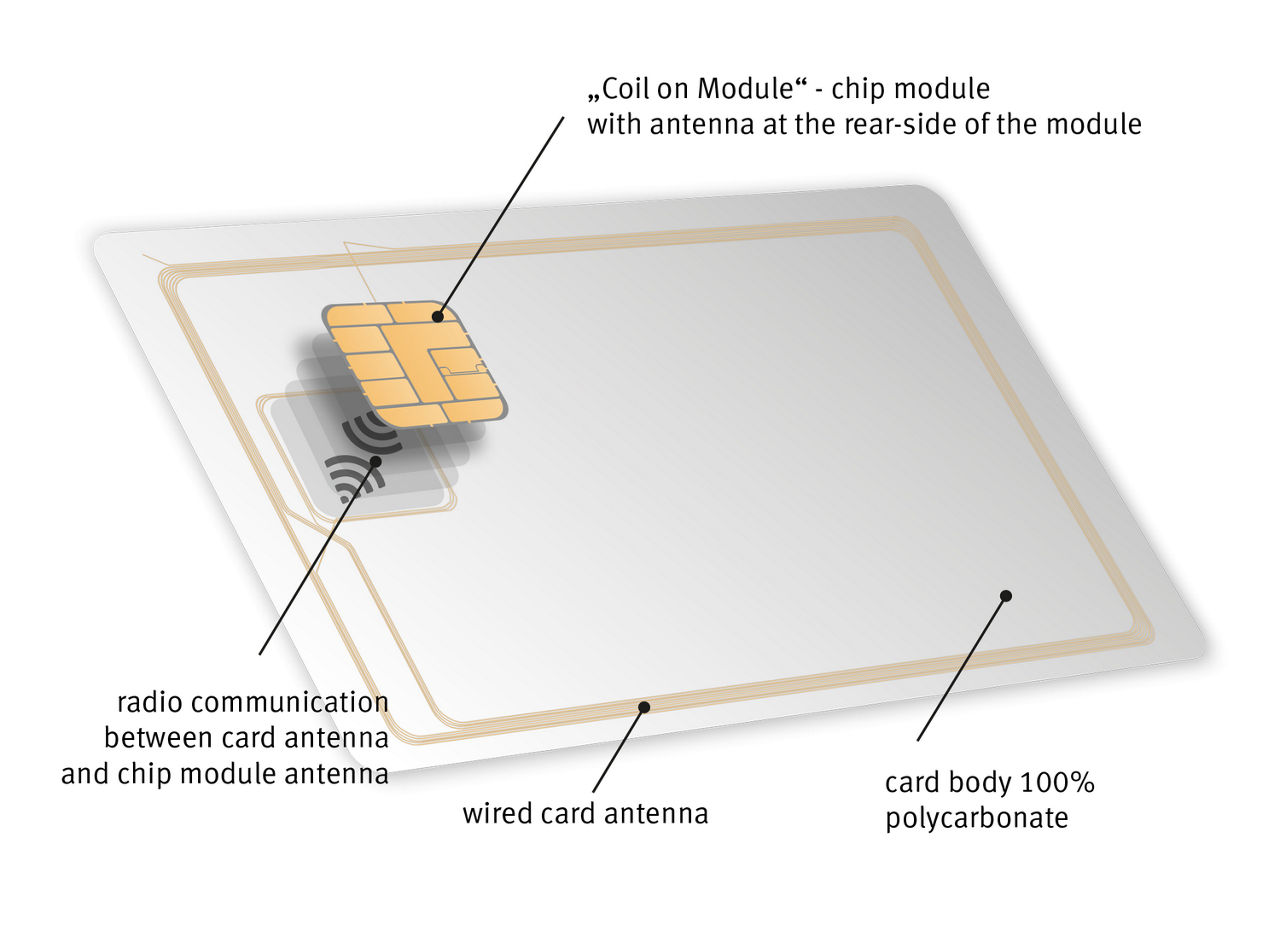

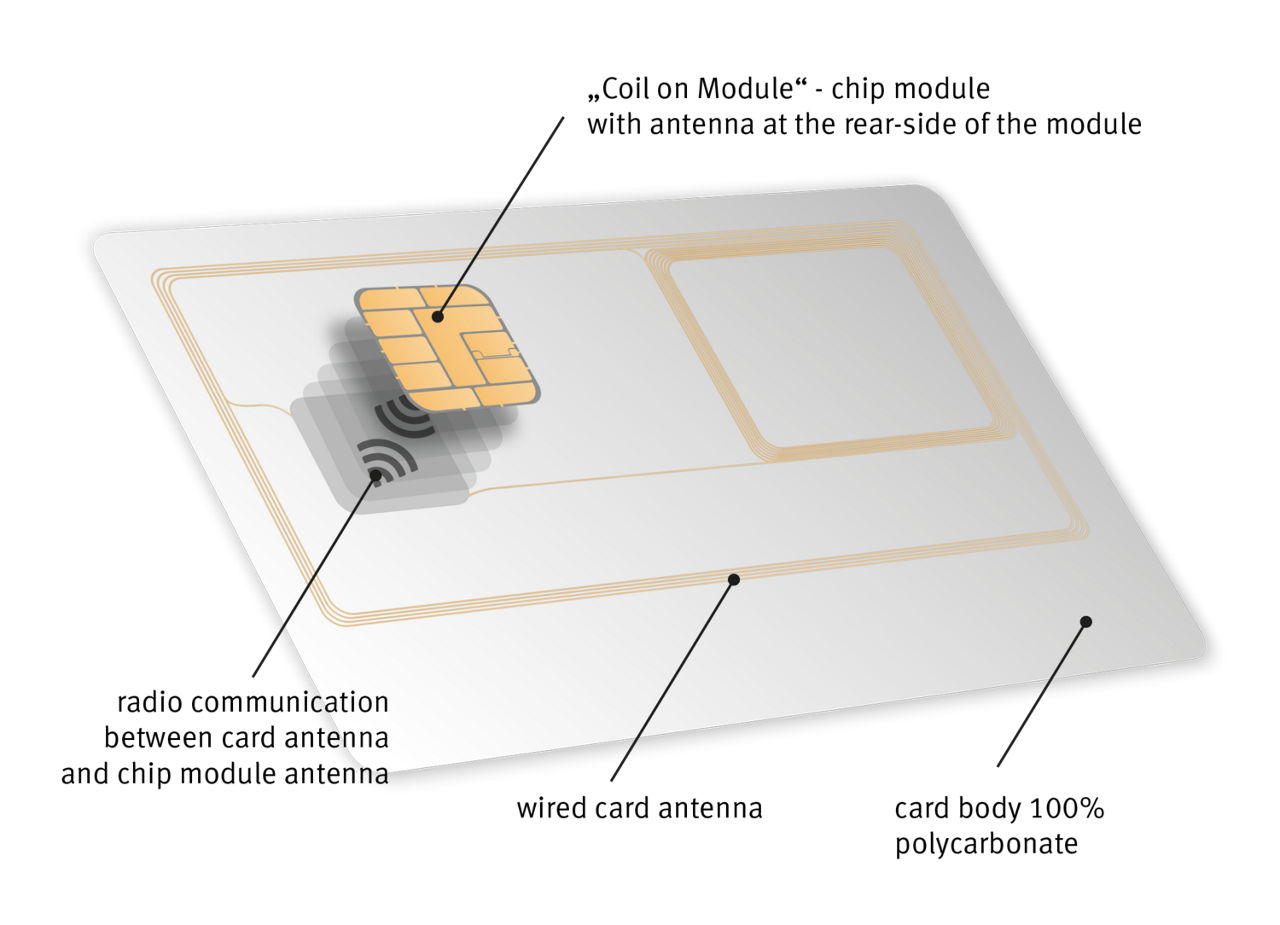

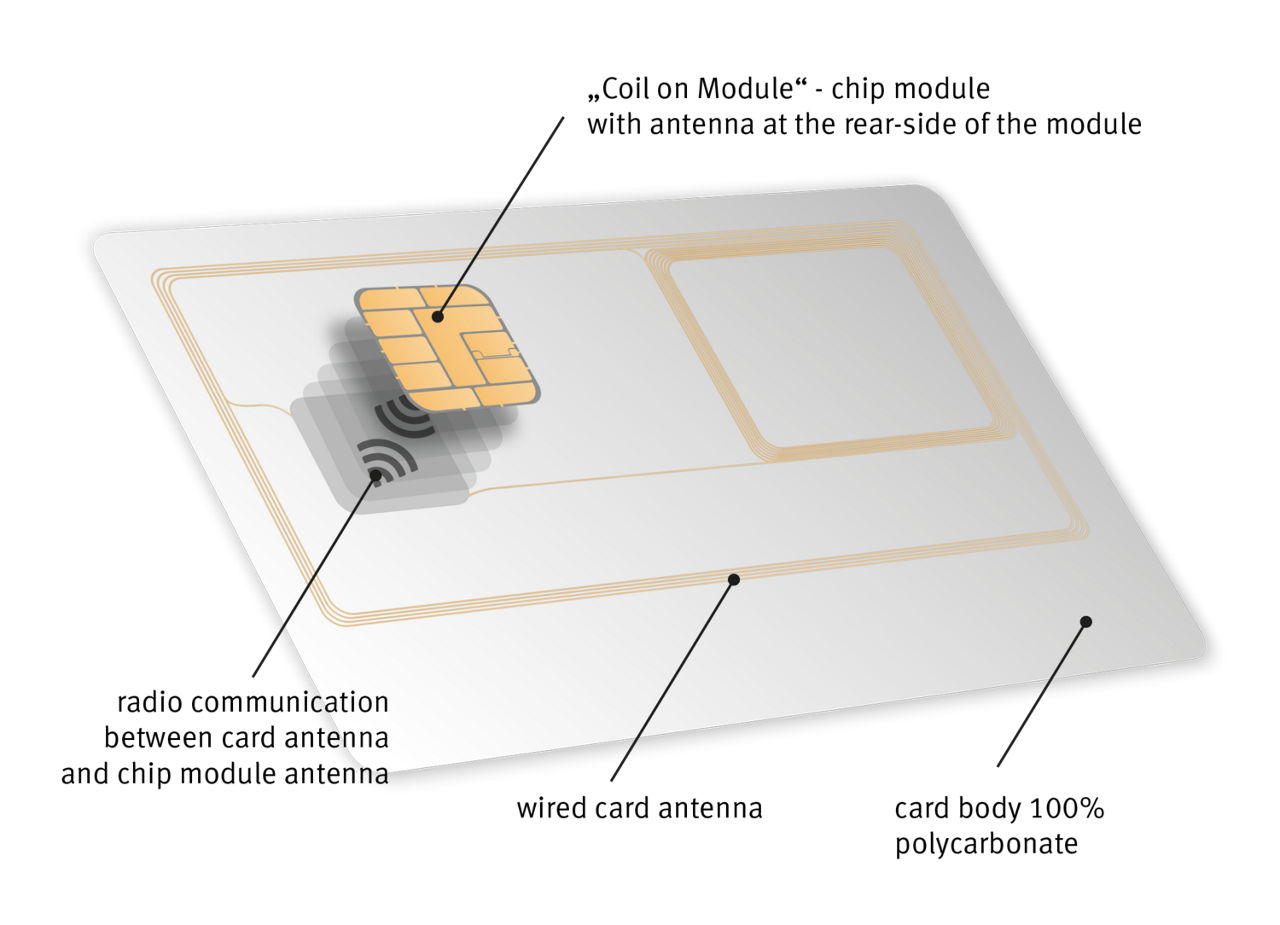

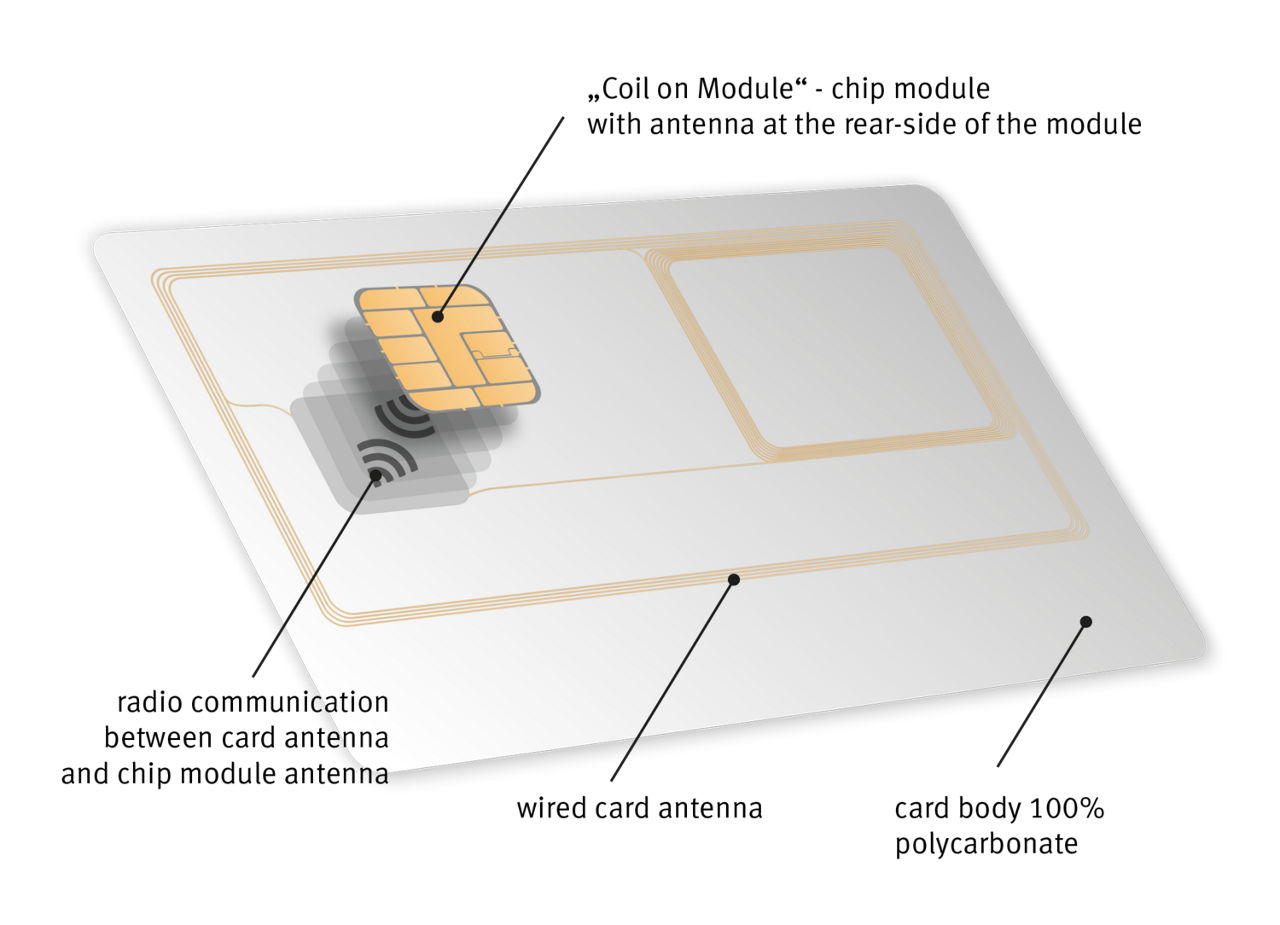

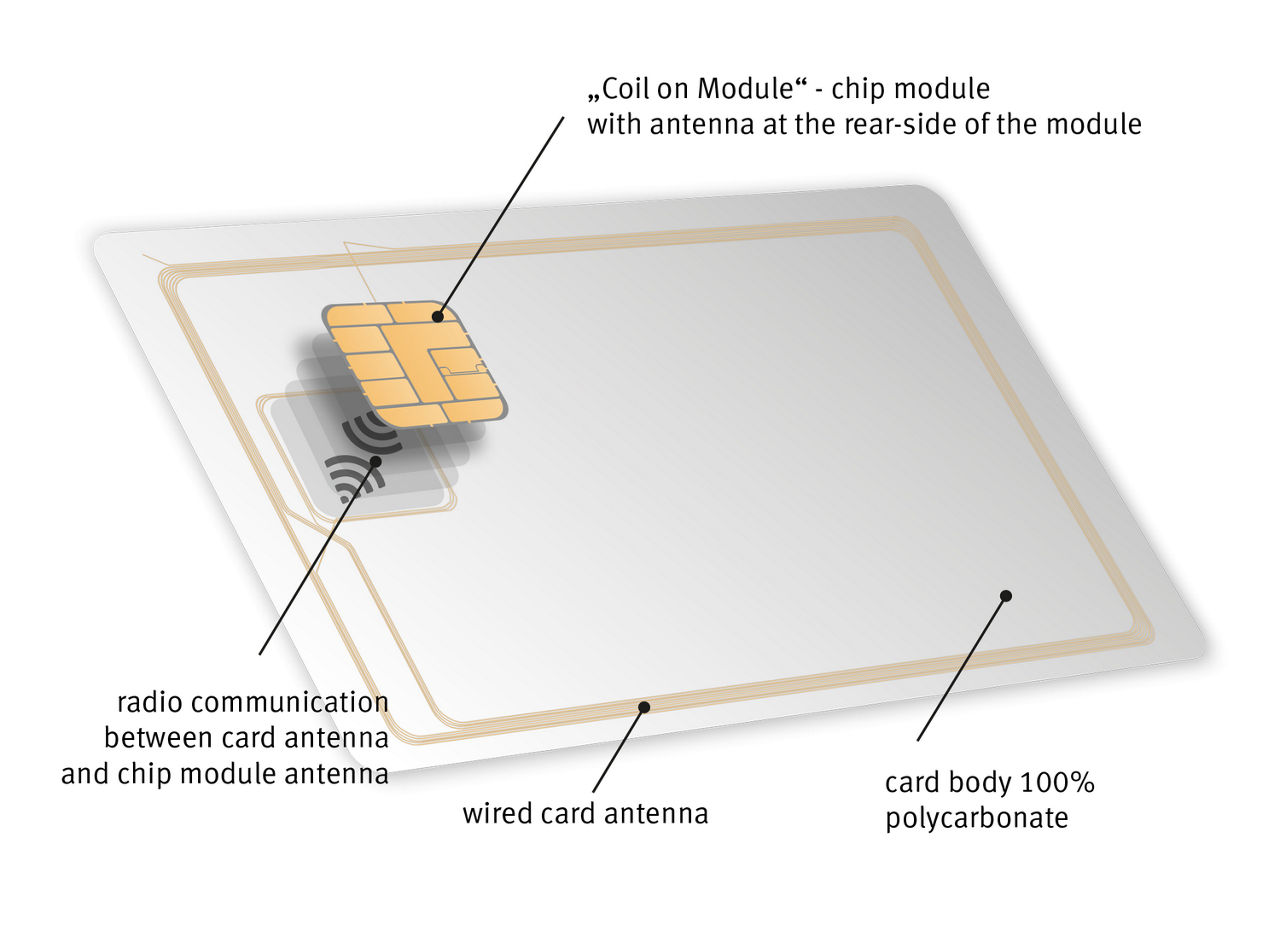

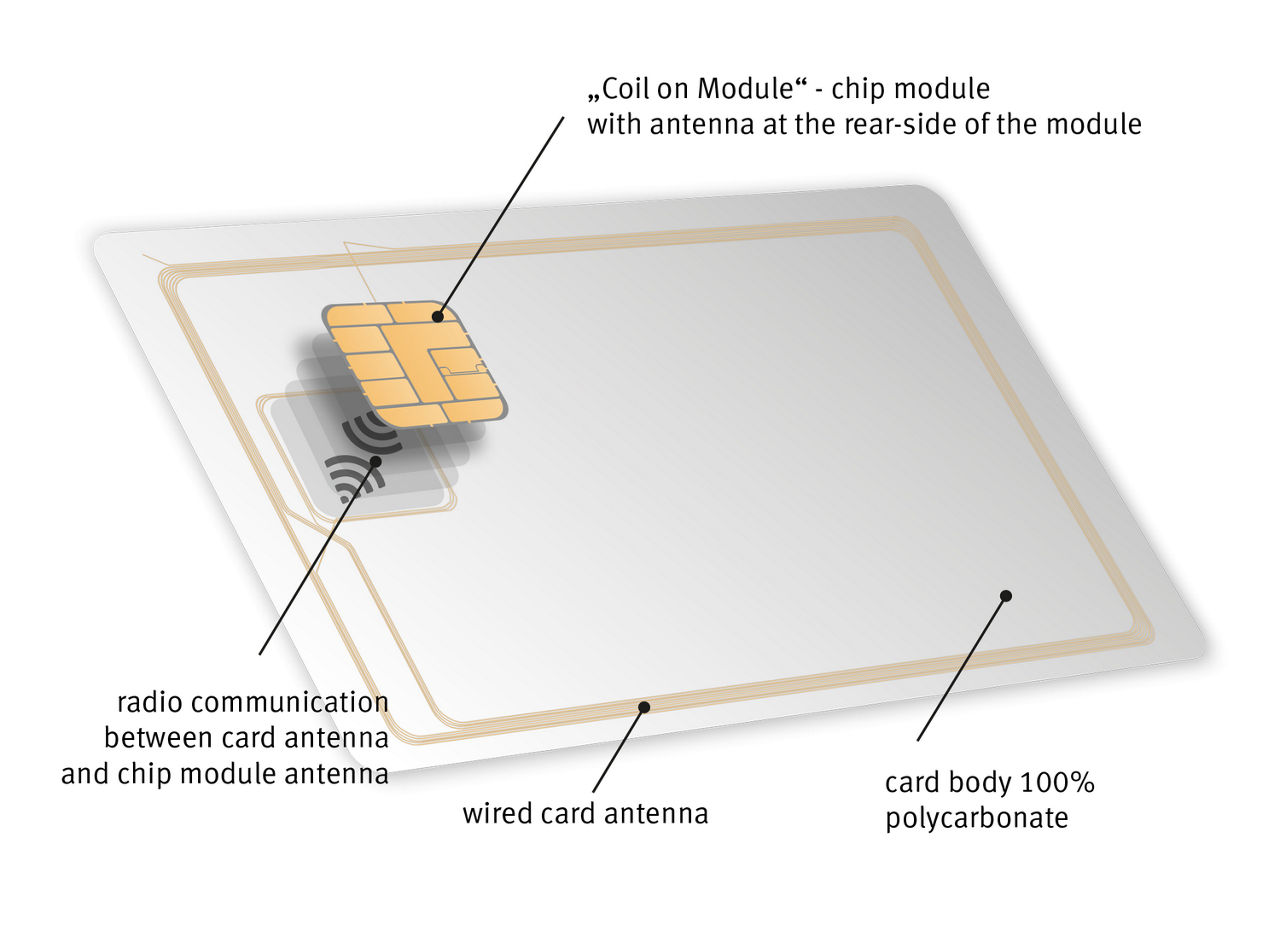

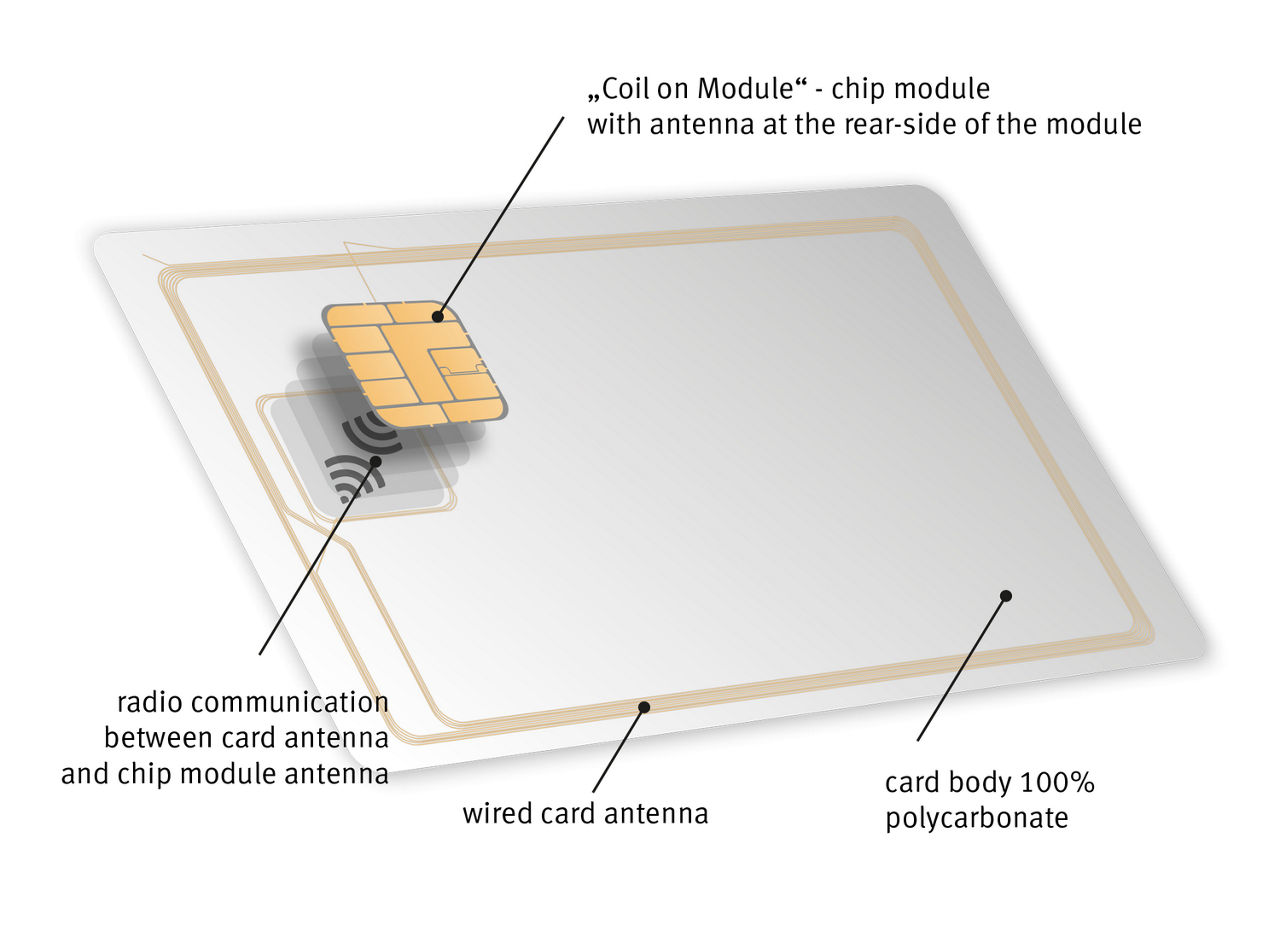

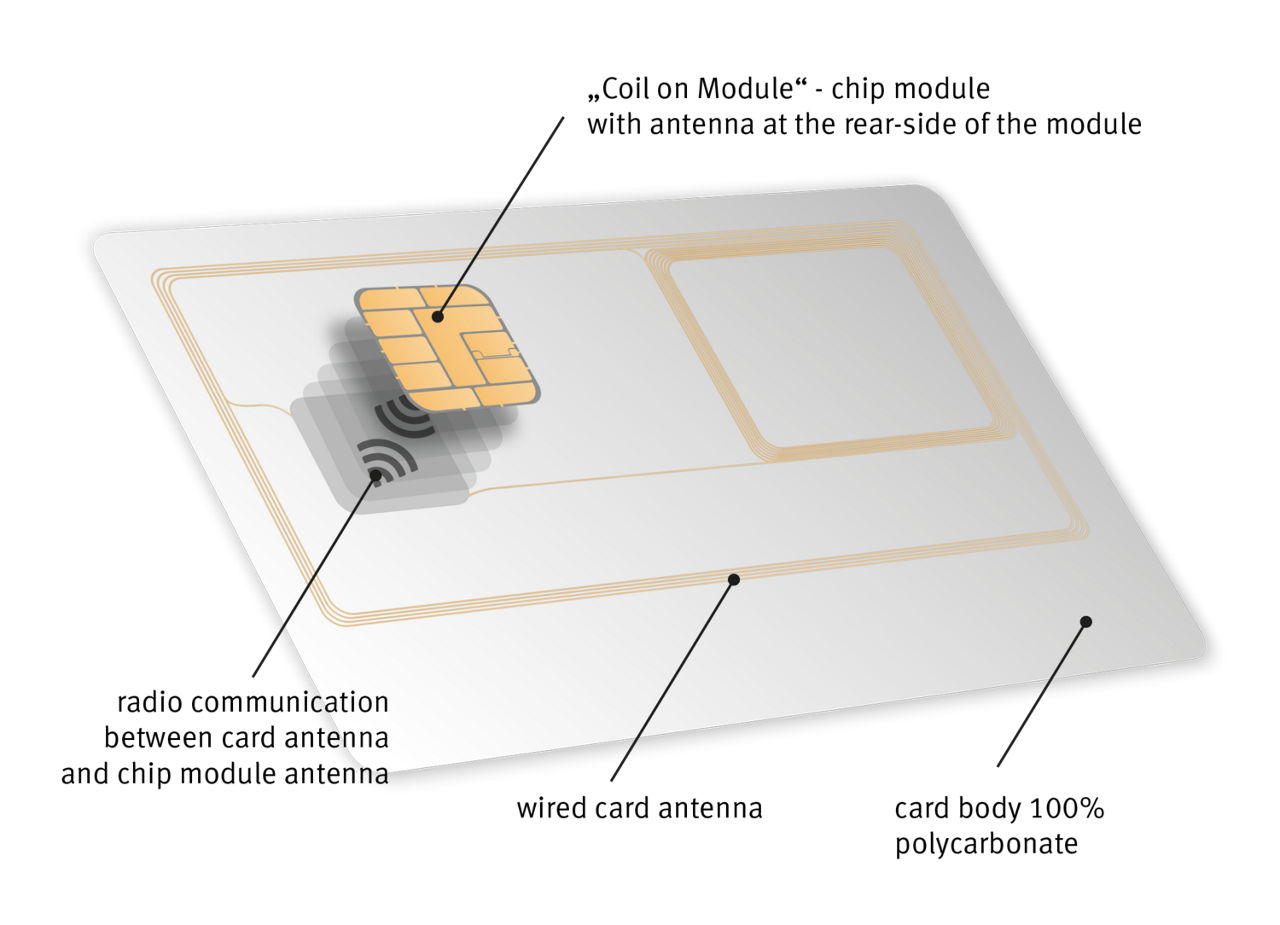

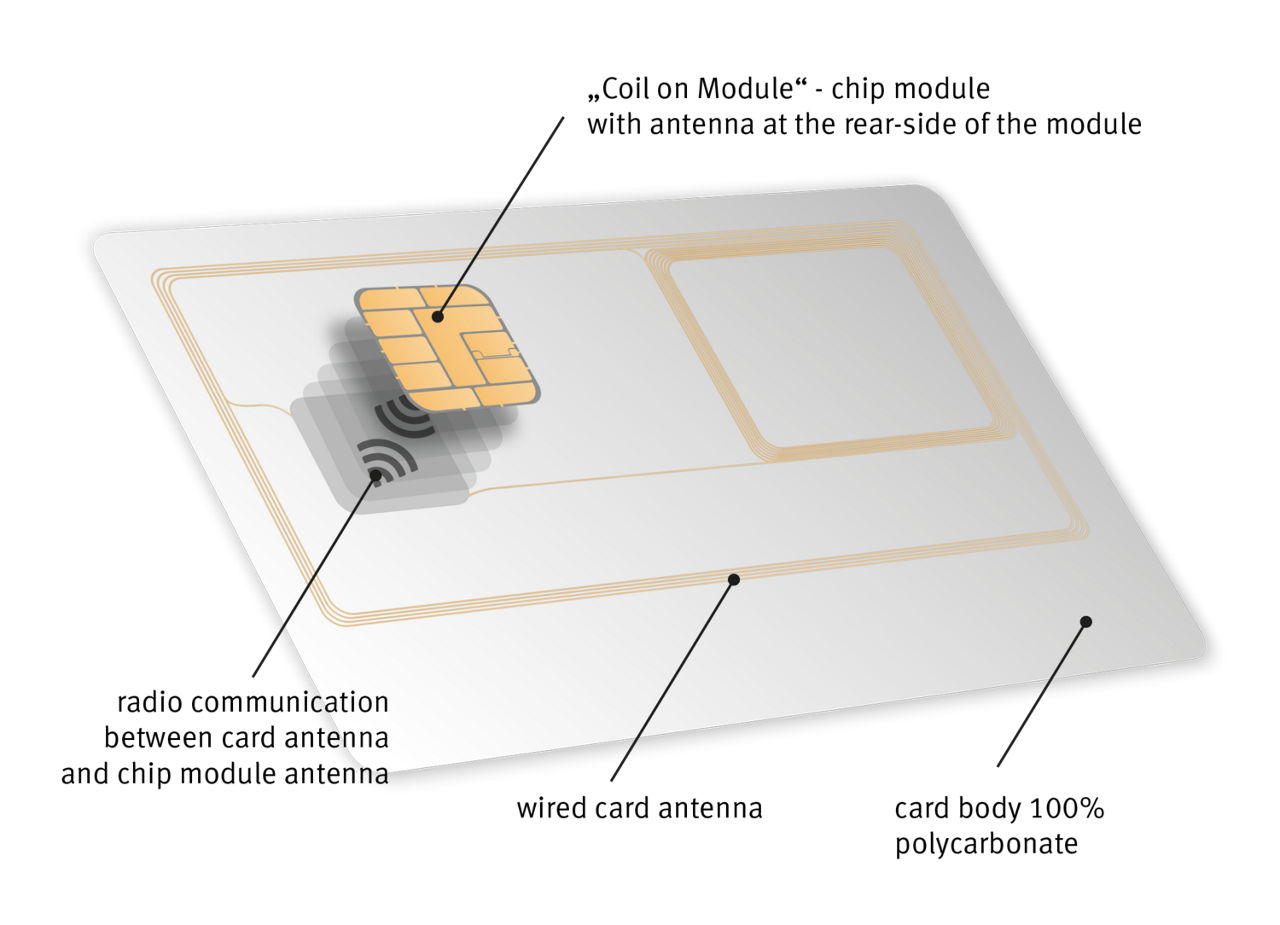

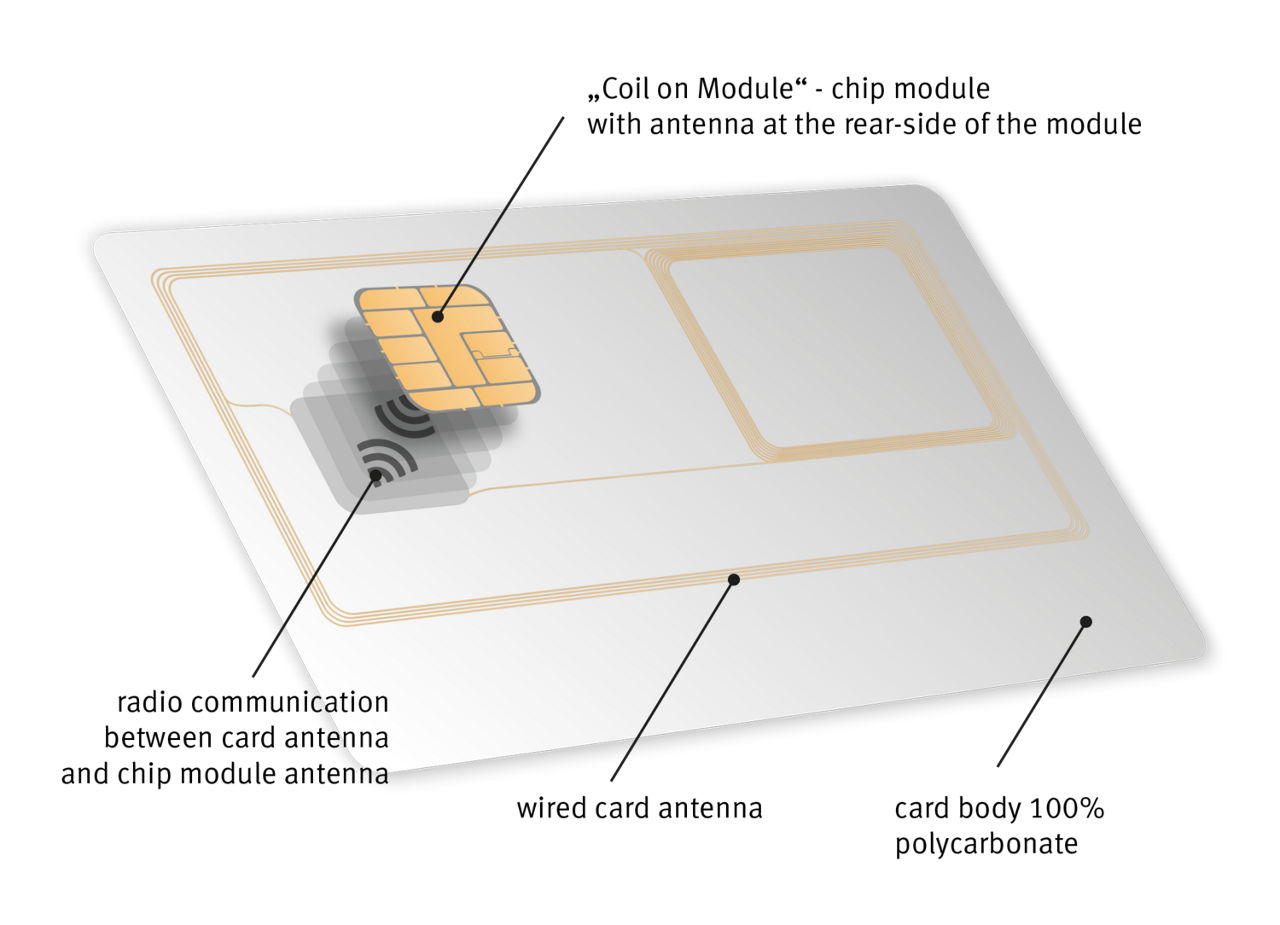

Coil on Module chip packaging technology

This innovative dual- interface chip packaging technology from Infineon is designed to increase the durability and robustness of smart cards.

Today’s contactless and DIF cards don’t have it easy. Stuffed into a wallet, they get sat on, bent, twisted, squashed and thrown about all day long. What’s more, they get pulled out and shoved back in to the wallet every time the user wants to buy a coffee, ride the subway, enter a building, pay for shopping or collect a prescription from the drugstore. The constant mechanical strain through rough daily handling means that the conventional physical connection between the radio frequency (RF) antenna and the card module can easily snap. And it frequently does.

In an increasingly mobile world, consumers are demanding fast, easy access to multiple services from a single card or device. This is fueling a move away from previously contact-based applications such as payment and identification towards contactless and dual-interface (DIF) multi-purpose schemes.

Fast, flexible card production processes built on stable, agile supply chains are essential to allow rapid rollout of competitive, customized offerings. Here optimized solutions bundling chip, module and antenna can give manufacturers a valuable lead.

Alongside security, durability has thus become a key success factor for multi-application cards. Card manufacturers need solutions with a robust design that complies with strict tender requirements governing factors such as tamper resistance and lifetime.

Infineon’s packaging innovations are designed to increase the durability and robustness of smart cards while at the same time reducing cost for the manufacturer.

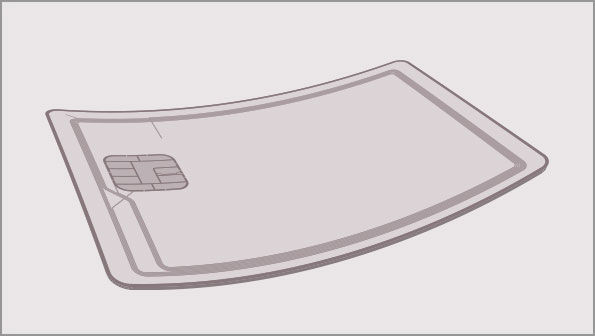

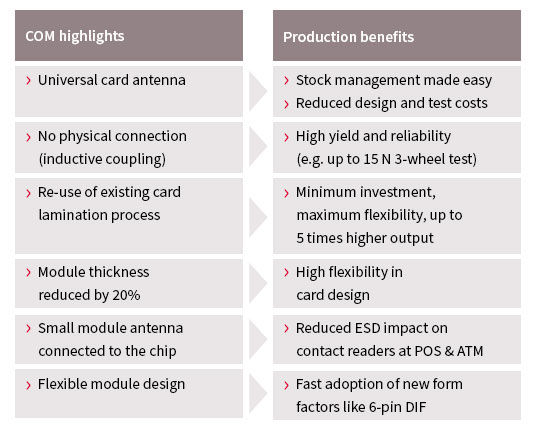

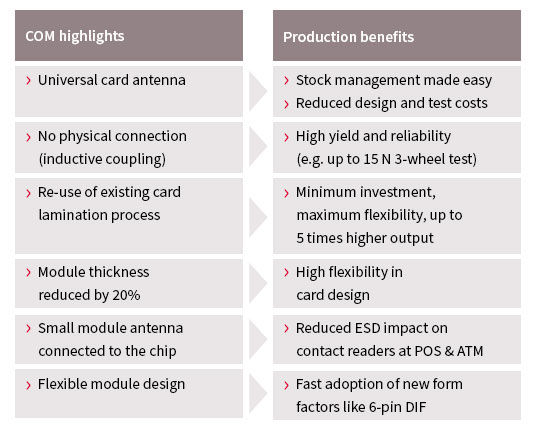

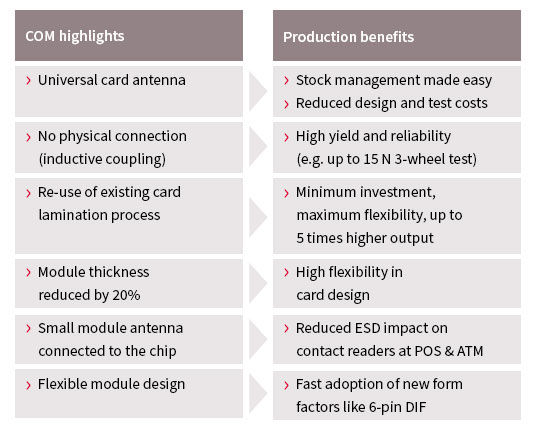

Coil on Module (CoM), our award-winning dual interface chip packaging technology, uses a radio frequency (RF) link instead of the mechanical/electrical connection typically used between the card antenna and the module.

This inductive coupling, along with a robust polycarbonate monoblock, greatly increases the robustness and long-term reliability of contactless and DIF cards in the field. Consequently, CoM enables lifetimes of ten years and more – essential for identification documents.

With our field-proven, plug & play packaging technology based on inductive coupling, we offer our customers a smart solution for the transition from contact-based to contactless using CoM DIF cards. Our CoM packages featuring polycarbonate monoblocks meet all security and robustness requirements for government identification or payment cards in particular, effortlessly overcoming the weak spot in today’s dual-interface card designs.

Maintaining lean production processes identical to those deployed in contact-based environments, our customers can look forward to immediate, high-speed volume production without having to invest in any new or special machinery. In addition, they benefit from a simplified, secure supply chain with reduced stock levels as one antenna supports all chip/module combinations.

As the leading provider of security solutions with a track record stretching back more than 30 years, we have developed an excellent worldwide sales and customer support structure over time. Presenting a single point of accountability, our one-stop, global offering extends beyond chips to include the operating system, module and antenna for reduced production complexity.

Application brochures

Application brochures

ID card manufacturers face a number of production challenges. On the one hand, they are looking for ways to support contactless or DIF functionality without complicating their production landscape. This entails mitigating costs by avoiding capital investments, saving on consumables, maximizing production yield and taking a lean approach to stock management. Ready-to-run solution bundling the security chip with a module and an antenna can accelerate time-to-market here by simplifying production. And, on the other, they face growing space constraints as a result of new card constructions e.g. with additional security or transperent layers that limit the area available on the card for the module.

- S-COM10.6 with inductive coupling

- Wire-embedded class 1 (ISO14443) card antenna on PC

- re-use of existing card lamination process

- Full compliance with PC monoblock security requirements

- PVC and PET-G also available

- One universal card antenna for any chip / module combination

- Available in solution bundles combining high-security SLE 77, SLE 78 and SLC52G controllers and operating systems

Given their security-critical nature, government ID cards have to be designed to the very highest standards to enable robust protection against fraud and tampering. They are required to maintain this performance over a minimum ten-year period – which is significantly longer than typical payment or loyalty cards, for instance. In addition, identification cards are increasingly being merged with payment or other applications, which requires manufacturers to implement contactless or dual-interface (DIF) production capabilities.

Infineon has developed an innovative inductive coupling technology. Coil on Module (CoM) replaces traditional electro-mechanical links with inductive connections. This entails placing a small antenna directly on the chip module. This connects with a coupling area on a standard-size antenna in the card using an electromagnetic field within the card body. This radio frequency (RF) connection resolves space constraints, as the chip module is almost 30% slimmer than common modules. In addition, the wire embedded antenna fully supports the polycarbonate (PC) monoblock concept which is stronger, more robust and more flexible than mixed material designs, allowing full compliance with the extended lifetime requirements of ID documents. Moreover the module also supports customized designs like featuring a logo on the module. Last but not least, with CoM, card manufacturers do not need to invest in new equipment to support DIF functionality, as the production process flow is similar to contact-based card production.

Learn more about the innovative packaging technology from Infineon, designed to increase the durability and robustness of smart cards. And at the same time, reducing costs for the manufacturer.

In response to these market trends, card manufacturers face a number of production challenges. These include higher complexity for dual interface card production, cost efficiency and time-to-market pressures. Contemplating a transition to a contactless or DIF scheme, many manufacturers are therefore looking to mitigate costs by avoiding capital investments, saving on consumables, maximizing production yield and taking a lean approach to stock management. Ready-to-run solution bundling the security chip with a module and an antenna can accelerate time-to-market here by simplifying production.

- S-COM8.4 and S-COM8.6

- Re-use of existing card lamination process

- Wire embedded card antenna on PVC base material

- Card production with high production yield and reliability

- Optimized for 4-line embossing of payment cards

- Tailored to customer sheet layout

- One universal card antenna design for different chip/module combinations

- Enables paper approval process based on reference approvals at the payment schemes

- Reduced ESD impact on contact readers, POS & ATMs

- Fast adoption to new form factors like 6-pin DIF

- Available as part of the SECORATM Pay solution offering combining high-security SLE 77 and SLC 32P controllers and operating systems

The payment market is moving away from cash and contact-based cards in response to consumer demands for convenient digital payment experiences. Consequently, smart card technology is making its way into more and more mobile devices, wearables and Internet-connected things. Driven by MasterCard/VISA, the market is also migrating to dual-interface schemes. These combine both contact-based and contactless functionality based on the EMV standard. This offers enhanced authentication functionality, greater protection against fraud and tampering, and seamless interoperability – all key success factors in the payment business.

We have developed an innovative inductive coupling technology that bridges the gap between today's contact-based payment applications and tomorrows contactless or dual-interface world. Coil on Module (CoM) addresses todays reliability and robustness issues by replacing the mechanical connection between the module and the antenna with a radio frequency link. This eliminates issues such as damage to the antenna and lack of contact between the module and the antenna during the personalization process. CoM improves the performance and reliability of the final product.

In addition, this assembly solution simplifies stock management, increases manufacturing yield and thus cuts manufacturing costs. Even more to the point, it is a low-investment option as it is fully compatible with existing contact-based production equipment. To further simplify rollout, CoM is available with pre-certified reference solutions for VISA/MasterCard.

The 2013 Global Frost & Sullivan Award for New Product Innovation Leadership went to our Coil on Module (CoM) packaging technology. Each year, Frost & Sullivan presents this award to the developer of an innovative element in a product that leverages leading-edge technologies. The award recognizes the value-added features/benefits of the product and the increased ROI it offers customers.

Frost & Sullivan acknowledged our CoM chip package and related card antenna designs for their ability to accelerate the introduction of cards that can be used for both contact-based as well as contactless applications. Highlights cited by the research and consulting organization include improved card robustness, up to five times faster manufacturing processes, flexible card design and minimal investments in new manufacturing equipment. It predicts that banks and financial institutions will benefit from improved performance, longer lifetimes and simplified supply chains for the final products.

“Infineon is a leading manufacturer of semiconductor solutions, which has enabled it to gain deeper expertise in manufacturing processes and subsequently, on ways to improve chips and packaging technologies,” said Frost & Sullivan Global Program Director, Digital Identification, ICT, Jean-Noel Georges. “Leveraging this experience, the company has developed a complete solution for dual-interface cards that bridges the gap from todays contact-based applications to tomorrows contactless world."

ID card manufacturers face a number of production challenges. On the one hand, they are looking for ways to support contactless or DIF functionality without complicating their production landscape. This entails mitigating costs by avoiding capital investments, saving on consumables, maximizing production yield and taking a lean approach to stock management. Ready-to-run solution bundling the security chip with a module and an antenna can accelerate time-to-market here by simplifying production. And, on the other, they face growing space constraints as a result of new card constructions e.g. with additional security or transperent layers that limit the area available on the card for the module.

- S-COM10.6 with inductive coupling

- Wire-embedded class 1 (ISO14443) card antenna on PC

- re-use of existing card lamination process

- Full compliance with PC monoblock security requirements

- PVC and PET-G also available

- One universal card antenna for any chip / module combination

- Available in solution bundles combining high-security SLE 77, SLE 78 and SLC52G controllers and operating systems

Given their security-critical nature, government ID cards have to be designed to the very highest standards to enable robust protection against fraud and tampering. They are required to maintain this performance over a minimum ten-year period – which is significantly longer than typical payment or loyalty cards, for instance. In addition, identification cards are increasingly being merged with payment or other applications, which requires manufacturers to implement contactless or dual-interface (DIF) production capabilities.

Infineon has developed an innovative inductive coupling technology. Coil on Module (CoM) replaces traditional electro-mechanical links with inductive connections. This entails placing a small antenna directly on the chip module. This connects with a coupling area on a standard-size antenna in the card using an electromagnetic field within the card body. This radio frequency (RF) connection resolves space constraints, as the chip module is almost 30% slimmer than common modules. In addition, the wire embedded antenna fully supports the polycarbonate (PC) monoblock concept which is stronger, more robust and more flexible than mixed material designs, allowing full compliance with the extended lifetime requirements of ID documents. Moreover the module also supports customized designs like featuring a logo on the module. Last but not least, with CoM, card manufacturers do not need to invest in new equipment to support DIF functionality, as the production process flow is similar to contact-based card production.

Learn more about the innovative packaging technology from Infineon, designed to increase the durability and robustness of smart cards. And at the same time, reducing costs for the manufacturer.

In response to these market trends, card manufacturers face a number of production challenges. These include higher complexity for dual interface card production, cost efficiency and time-to-market pressures. Contemplating a transition to a contactless or DIF scheme, many manufacturers are therefore looking to mitigate costs by avoiding capital investments, saving on consumables, maximizing production yield and taking a lean approach to stock management. Ready-to-run solution bundling the security chip with a module and an antenna can accelerate time-to-market here by simplifying production.

- S-COM8.4 and S-COM8.6

- Re-use of existing card lamination process

- Wire embedded card antenna on PVC base material

- Card production with high production yield and reliability

- Optimized for 4-line embossing of payment cards

- Tailored to customer sheet layout

- One universal card antenna design for different chip/module combinations

- Enables paper approval process based on reference approvals at the payment schemes

- Reduced ESD impact on contact readers, POS & ATMs

- Fast adoption to new form factors like 6-pin DIF

- Available as part of the SECORATM Pay solution offering combining high-security SLE 77 and SLC 32P controllers and operating systems

The payment market is moving away from cash and contact-based cards in response to consumer demands for convenient digital payment experiences. Consequently, smart card technology is making its way into more and more mobile devices, wearables and Internet-connected things. Driven by MasterCard/VISA, the market is also migrating to dual-interface schemes. These combine both contact-based and contactless functionality based on the EMV standard. This offers enhanced authentication functionality, greater protection against fraud and tampering, and seamless interoperability – all key success factors in the payment business.

We have developed an innovative inductive coupling technology that bridges the gap between today's contact-based payment applications and tomorrows contactless or dual-interface world. Coil on Module (CoM) addresses todays reliability and robustness issues by replacing the mechanical connection between the module and the antenna with a radio frequency link. This eliminates issues such as damage to the antenna and lack of contact between the module and the antenna during the personalization process. CoM improves the performance and reliability of the final product.

In addition, this assembly solution simplifies stock management, increases manufacturing yield and thus cuts manufacturing costs. Even more to the point, it is a low-investment option as it is fully compatible with existing contact-based production equipment. To further simplify rollout, CoM is available with pre-certified reference solutions for VISA/MasterCard.

The 2013 Global Frost & Sullivan Award for New Product Innovation Leadership went to our Coil on Module (CoM) packaging technology. Each year, Frost & Sullivan presents this award to the developer of an innovative element in a product that leverages leading-edge technologies. The award recognizes the value-added features/benefits of the product and the increased ROI it offers customers.

Frost & Sullivan acknowledged our CoM chip package and related card antenna designs for their ability to accelerate the introduction of cards that can be used for both contact-based as well as contactless applications. Highlights cited by the research and consulting organization include improved card robustness, up to five times faster manufacturing processes, flexible card design and minimal investments in new manufacturing equipment. It predicts that banks and financial institutions will benefit from improved performance, longer lifetimes and simplified supply chains for the final products.

“Infineon is a leading manufacturer of semiconductor solutions, which has enabled it to gain deeper expertise in manufacturing processes and subsequently, on ways to improve chips and packaging technologies,” said Frost & Sullivan Global Program Director, Digital Identification, ICT, Jean-Noel Georges. “Leveraging this experience, the company has developed a complete solution for dual-interface cards that bridges the gap from todays contact-based applications to tomorrows contactless world."