DC wallbox

Fast, efficient destination charging for your EV

There are currently more than 10 million electric vehicles (EV) on the road today with adoption steadily increasing as the technology becomes more affordable and convenient. Destination charging is the most important use case, as this is the form of charging most commonly used by electric vehicle users. DC wallbox technology will be the key element in the charging infrastructure, enabling faster and smarter charging.

The power and speed of DC charging – at home

The ability to charge at home is a critical selling point for EVs. Cost, availability, and easy installation are the key aspects of the users’ final decision. With the new DC wallbox technology, electric vehicles can be charged with a direct current (DC) with a power of up to 22 kW – that is more than twice as fast as using a typical wallbox that works with alternating current (AC). The DC-based wallbox technology transfers the electrical power directly to the traction battery via the standardized DC charging plug (as also used in fast and ultra-fast chargers). Unlike AC-based systems, electric vehicles are charged independently of their integrated on-board charger, so there is no limitation on charging speed and capacity as it is typically the case with AC charging infrastructure. Charging time can thus be significantly reduced.

Another important and innovative aspect of DC charging technology is the possibility of bidirectional power transfer. The power can flow in two directions to cover different use cases, such as bridging power shortages, as a buffer for the private households, or even reselling power to the grid with V2G (vehicle-to-grid) option in the future.

The availability of increasing battery capacities spread across countries has triggered a number of forward-looking concepts for integrating these energy sources into the existing electricity infrastructure. Homes and commercial buildings that charge EVs with renewable energy sources such as solar also intend to store the excess power and make it available again during power outages or to meet high demand peaks. This vehicle-to-building (V2B) approach will be further extended to address electricity demand at the national level and to balance electricity demand in the context of a broader shift to renewable energy with vehicle-to-grid (V2G) implementations.

Bi-directional implementation requires a specific topology cable of dual power transfer.

The process of charging an electric vehicle at a charging point must allow for the identification, authentication, and safeguarding of information that passes between the charger, the vehicle, and the backend infrastructure. This will require cryptography that will protect both the charging infrastructure but also the vehicles using it.

As part of the ISO 15118 international standard comes the concept of Plug & Charge. It allows charging vehicles without the need of presenting a dedicated charging card to the charging point. This enables a secured and convenient way of charging an electric vehicle, covering both wired and wireless charging technologies based on AC and DC subsystems. At its core, Plug & Charge is intended to ensure confidentiality, data integrity, and authenticity, which it achieves through the algorithms defined by ISO 15118 for symmetric and asymmetric cryptography.

Implementation of this standard can utilize a tamper-resistant microcontroller such as Infineon´s Trusted Platform Module OPTIGA™ TPM SLI 9670, which is a standardized component according to the TPM standard of the Trusted Computing Group (TCG). The TPM plays an essential role in securing the financial transaction of Plug & Charge by protecting the authenticity of the involved entities, the integrity of the exchanged data, and the confidentiality of sensitive information.

Furthermore, the OPTIGA™ TPM SLI 9670 is also used for the platform protection and the secured data transmission between a server backend, charging station, and the EV. This is required to secure remote functionalities like firmware updates, maintenance, and management of the charging infrastructure devices.

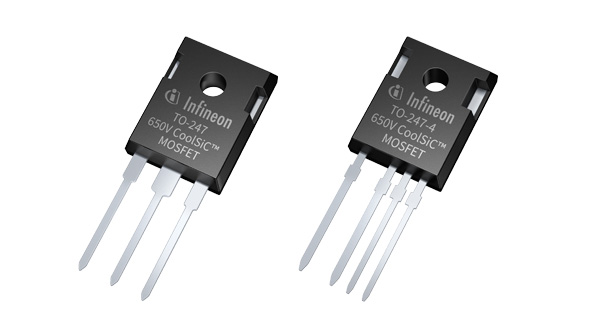

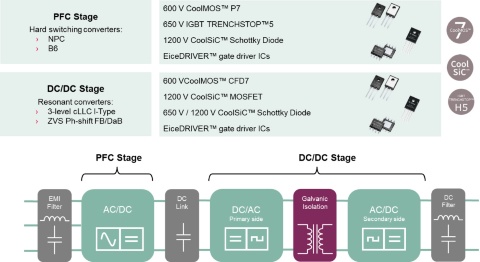

The power switches in the DC wall box are based on discrete solutions like CoolSiC™ MOSFET and CoolMOS™ MOSFET. Since every switch needs a driver, and every driver needs to be controlled, we offer the right EiceDRIVER™ gate driver ICs and XMC™ microcontroller. With our current sensor solutions, we can enable small and accurate current sensing. OPTIGA™ products ensuring data protection and security and finally communication and IoT devices based on the PSoC6™ platform round-up HMI and interface parts of the system.

| Power Range |

|

| Input AC/DC Stage |

|

| Output DC/DC Stage |

|

| Output Voltage Range |

|

Promoting a global standard

Infineon is part of the international Charging Interface Initiative e.V. (CharIN). CharIN’s goal is to develop, establish and promote a global charging system standard for all kinds of battery-powered electric vehicles.

Podcast4Engineers: Vision for eMobility: 10 kWh for 100 km

How do semiconductors ensure electric vehicles are efficient and fun to drive at the same time?

Listen to our newest Podcast4Engineers episode and join our experts Dirk and Christoph discuss how semiconductors not only enable #decarbonization in eMobility, but also ensure the “fun-to-drive” factor.

Podcast4Engineers: Fast EV charging

Today, a DC charger with 150 kW can put a 200 km charge on an EV in around just 15 minutes. As fast charging and battery technologies continue to evolve and improve in the near future, experts anticipate the charging time to drop even further. Listen to our Podcast4Engineers episodes as our Infineon experts discuss the latest trends and challenges in EV charging and how our one-stop product and design portfolio can help design energy-efficient DC EV chargers today.

自宅で電気自動車 (EV) を充電できるのは便利です。しかし、ウォールボックスはどうやって選択すればよいでしょうか。「専門家に質問」では、弊社の専門家ハカンがACウォールボックスの特長について説明します。

ACウォールボックスを接続し、安全に保つことが重要なのはなぜでしょうか。この「専門家に質問」では、当社の専門家であるHakanが、接続性がいかに充電をより便利で効率的にし、コストまで削減できるかを説明します。

Webinars

In the technical introduction training, you became familiar with the full-bridge transformer driver family 2EP, which is a reliable power supply that supports Infineon’s top-notch switches and isolated gate drivers. By the end of this deep dive, you will be able to describe the working principle of this family and know about possible applications by understanding the effect of input voltage changes, transformer transfer ratio, and duty cycle changes on the isolated output voltage.

This video will introduce you to the 2EP EiceDRIVER™ power family, along with its features and advantages. Additionally, you will have an overview of the extensive application scope of the 2EP.

As electro mobility increasingly becomes part of our daily lives, the need for more efficient charging solutions is growing. With an eye on the requirements and technological developments in this field, the challenge is to respond with smart and compact power conversion solutions for the charging networks of today and tomorrow. In this webinar, you will gain deeper insights, into Infineon's comprehensive DC-EV charging portfolio with a focus on silicon carbide and its important contribution to ultra-fast EV charging.

Today's global challenges of decarbonization, combined with rising energy demand, make bi-directional electric vehicle charging and how semiconductor solutions support this application more important than ever. In this webinar you will get an overview of the power conversion topologies for bi-directional DC charging and take a closer look at an application example based on Infineon's 50 kW Reference Design.

Online Courses

In depth introduction of Infineon's one stop shop reference design for EV traction Inverter.

- Understand Infineon’s purpose in delivering quality above and beyond the standard and find out how we execute that standard in development, qualification, manufacturing and testing

- Learn where and how this high-quality standard is reflected and discover our success stories

With the growing market of electrical vehicles, the industry has put forward more requirements for the performance of charging piles. This e-learning will show you that the emergence of CoolSiC™ MOSFETs has improved the charging pile industry to make the EV charger smaller, faster and with higher efficiency.

- Distinguish the features and benefits of Infineon’s CoolSiC™ solutions in target applications and identify Infineon’s fully scalable CoolSiC™ portfolio to meet this automotive market transition

- Explain the reasons for the increasing introduction of silicon carbide technology in the automotive applications

This training covers the harmonized frame of standards from international bodies like ISO, IEC, SAE and UL dedicated to the Wireless Power Transfer system technologies.

In this online course you will learn about cost-optimized, but highly efficient electric vehicles charging solutions based on IGBT and CoolMOS™, and explore Infineon’s wide portfolio that supports every segment of the EV charging application.

This training covers the most relevant standards for high power charger design, grouped into 4 major areas:

• charging topology

• communication

• accessories

• safety and security

- The training covers detailed information about Infineon's 3rd generation automotive EiceDRIVER™ 1EDI305xAS

- Participants will learn how these products help to reduce switching losses and improve thermal efficiency, resulting in longer range for hybrid and electric vehicles

Every switch needs a driver, and the right driver makes a difference.

Infineon offers different isoalted gate driver families, such as the EiceDRIVER™ Compact and the EiceDRIVER™ Enhanced. Each family has different features to protect the switch and application.

The EiceDRIVER™ isolated gate driver offers advanced features such as reinforced isolation, Miller clamp, slew rate control and short circuit protection to protect the switch and application. It also enables condition monitoring and rapid prototyping.

The EiceDRIVER™ is the perfect fit for industrial application, particular in combination with Infineon CoolSiC™ and IGBT switches.

Training topics:

- Get to know how AURIXTM is able to answer the needs of the electric vehicle market

- Recognize and explore how AURIX™ TC3xx addresses key electric vehicle challenges, and understand the main features of the AURIX™ TC3xx microcontroller

In this training you will:

- Be familiar with silicon carbide MOSFET structures and their characteristics

- Get to know Infineon's CoolSiC™ MOSFET, its features, its improvements over a typical trench MOS and how it performs against its competitors

In this training you will:

- Get to know Infineon’s IPOSIM tool, specifically for an automotive electric vehicle inverter

- Discover the steps involved in simulating different parameters and comparing the results of different Infineon products to see which is the best fit for your application

In this training you will:

- Learn about the transition from fule injection combustion engine to full battery electric vehicles and the main 48V powered applications.

- Additionally get an overview about Infineon’s comprehensive MOSFET portfolio for 48 V applications and their support material

- Infineon's HybridPACK™ Drive silicon carbide compact power modules cater to the increasing demand for high range, efficiency, and power in electrified vehicles, enabling longer drive range, compact size, and optimized system cost.

- The second generation of Infineon's HybridPACK™ Drive, utilizing CoolSiC™ technology, offers a scalable product family with enhanced features and package improvements, providing added value to customers.