How does a factory get smart, digitized, automated and efficient?

Empowering the smart factory

Geopolitical crises, raw material shortages and sustainability regulations are just some of the challenges facing manufacturers. The use of smart factory technologies can help manufacturers meet these challenges and also reap many benefits.

The goal of Industry 4.0 is to create autonomous production in which people, machines, systems and products communicate with each other independently. The result are intelligent value chains and product life cycles in which not only production is controlled, but also the entire value chain, from suppliers and producers to customers can be optimized. This brings a lot of benefits: smart factories can achieve greater productivity and growth, ensure high quality and reduce the risk of human error, provide the right data for analysis and optimization purposes, minimizie downtime and disruptions through predictive maintenance, safeguard the supply chains from disruptions, offer customized products, meet sustainability commitments - to ultimately become more competitive.

What makes a factory smart?

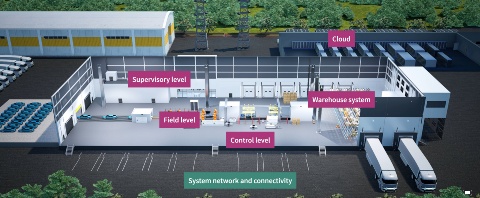

For the smart factory to function, the following requirements must be met:

- Smart usage of data, collected and communicated via ubiquitous, reliable connections: While production is running at full speed huge amounts of data are collected. It is essential to collect, analyse, understand, and deploy this massive amount of data effectively and securely. Therefore reliable and secured connectivity of people, machines and "things" in physical and virtual domains via wired and wireless technologies is the heartbeat of every smart factory, allowing high-speed communication for complex automation.

- Autonomous production with transparent and flexible supply chains: Innovative automation solutions bring increased quality, accuracy and precision to industrial processes by creating an ecosystem of sensors, machines, robotic devices and other instruments connected together, communicating and exchanging data with both internal and external software automation systems. Real-time and end-to-end visibility, shared with all participants, enables smart and resilient supply chains. Issues can be anticipated at an early stage and therefore prevented before they occur.

- Keeping a finger on the pulse: New technologies and developments, for example in the areas of machine vision, augmented reality, AI and machine learning, robotics, predictive maintenance and condition monitoring, can help to keep the smart factory even more efficient, flexible and resource-saving.

- Sustainability: Rising energy demand while optimizing energy efficiency and reducing CO2 emissions can be achieved by reliable data that can lead to energy savings by uncovering inefficient production flow, optimizing production and logistics planning, and anticipating maintenance needs. Smart semiconductor solutions are the essential gatekeepers for these developments and innovations. At many automation touchpoints they ensure efficient and secure data flow, control the speed of industrial motors and facilitate unexpected gains in overall flexibility.

Discover our solutions for smarter factories:

SENSE: Data transparency for Industry 4.0

The emergence of smart factories is also creating new opportunities for the deployment of 3D image sensors in industrial robots, in monitoring and vision systems and in automated guided vehicles. Infineon’s REAL3™ time-of-flight image sensors let electronic devices acquire a real 3D map of the scene in front of the machinery and equipment. Advanced software and hardware know-how give ToF systems the ability to work reliably in tough environments characterized by strong ambient light, harsh conditions and challenging objects.

COMPUTE: Signal processing and control

The 32-bit-Microcontroller TriCore™ family delivers the versatility required for the industrial sector, excelling in optimized motor control applications and signal processing. AURIX™ TriCore™ unites the elements of a RISC processor core, a microcontroller and a DSP in a single MCU.

We expect the intelligent machines and solutions in smart factories to work anytime, anywhere. At the same time, they should offer maximum safety and flexibility. Rely on our broad portfolio of secure and reliable solutions for embedded systems and check out our safe, secure, and reliable NOR Flash products.

To meet the challenges of next-generation factory automation systems, high-performance non-volatile memories must ensure that no data is at risk, must work reliably in harsh operating environments, and must support long-term and guaranteed back-up - all while operating at high speeds with minimal power consumption. Check out how Infineon's EXCELON™ F-RAM is the ideal data-logging memory for smart factories.

ACTUATE: Empowering industrial automation

Benefit from our wide portfolio of smart switches for highly integrated and discrete I/O module solutions. We provide a comprehensive portfolio of isolated I/O devices (ISOFACE™), high-side (PROFET™) and low-side switches (HITFET™) matching requirements for lowest system heating up and a maximum of channel density.

Rely on our intelligent power modules (IPMs) and discretes for your designs in the low-power range of motors or drives. Our EasyPIM™, EasyPACK™ and EconoPIM™ modules are the perfect match for medium-power drives. EconoDUAL™ and PrimePACK™ are the solutions of choice in the high-power spectrum. CoolSiC™ MOSFETs are an attractive solution for high-speed drives and inverter integration, since they reduce switching and conduction losses, especially under partial load conditions. For battery-powered applications like automotive brushless DC motors, customers count on our wide range of silicon MOSFETs, including our OptiMOS™ family.

We also offer gate driver ICs for all silicon and silicon carbide (SiC) devices, complementing our power semiconductors. Our broad EiceDRIVER™ portfolio ranges from basic to enhanced functionality.

CONNECT: From IOs to high-speed-communication

Infineon’s industrial CAN transceiver portfolio complies with ISO11898 and addresses requirements such as a CAN FD data rate up to 8 Mbit/s, receive-only mode and bus wake up. The range includes solutions optimized for high-speed communication, providing the highest reliability, as well as transceivers that address microcontrollers with 3.3 V logic IOs. Advanced tiny packages are in the making.

Wireless technologies like Wi-Fi®, Bluetooth® technology for content streaming and Bluetooth Low Energy technology for ultra-low-power connectivity form the backbone of the IoT and are also shaping Industry 4.0. Infineon seamlessly integrates all these technologies to provide state-of-the-art, interoperable solutions for all kind of industrial applications.

SECURE: Scalable, easy-to-integrate security solutions

The OPTIGA™ security solution family is designed for easy integration into embedded systems to protect the confidentiality, integrity and authenticity of information and devices. These hardware-based security solutions range from basic authentication chips to sophisticated implementations. The OPTIGA™ Trust family includes turnkey products for smaller platforms as well as programmable solutions, while OPTIGA™ TPM (Trusted Platform Module) products are ideal for embedded PC, mobile and computing applications. OPTIGA™ Connect IoT devices enables secured and dependable cellular connectivity, even in harsh environments.

Every day, manufacturing companies rely on systems that depend on NOR Flash technology to prevent accidents and secure sensitive data. The advanced, secured, and easy-to-use SEMPER™ Secure NOR Flash portfolio delivers security, safety, and reliability to smart factories at a low total cost-of-ownership. It is built on the proven SEMPER™ NOR Flash family, combines advanced security with industry-leading functional safety and reliability, and is engineered to last a lifetime.

Smart usage of data and ubiquitous, reliable connections

The smart factory thinks & steers

To make smart production at all possible, existing systems, machines, robotic arms, etc. must be networked to collect data. This is possible with robust connectivity and industrial sensors.

Networking systems with each other

- Wired communication

In the smart factory of the future, sensors, machines, devices and IT systems interact with each other. To do this, they must exchange a wide range of data and information. Wired communication still dominates the connectivity of different hierarchy levels within the connected factory. Whether it is the connection of sensors, actuators, motors and drives to an industrial control system or high-level communication to or from a cloud via Ethernet or proprietary fieldbus systems, a secure, robust and reliable exchange of information is required, partly based on real-time properties. From transceivers, PHYs, peripherals on microcontrollers to standalone communication controllers, Infineon offers a range of wired communication devices supporting different protocols and communication standards. In terms of data security and integrity, Infineon's high-security microcontrollers based on leading hardware-based security are the right choice.

- Wireless communication

With mobile robots, automated guided vehicles and other mobile devices becoming more widespread – in particular on the factory floor -, wireless information and command exchange approaches are increasing its market share. As a leading wireless controller and RF chip maker with strong focus on system understanding, Infineon provides WiFi, Bluetooth and corresponding RF solutions to support customers into taking their devices to the next level of digitalization.

Integrated solutions for factory sensors

In today’s high-tech factories, the sensors integrated in the machines or systems provide data on their current status and record variables such as position, speed, torque, temperature, utilization, humidity or pressure. These industrial sensors play an integral role in processing systems’ precision and reliability. But the sensors must be durable enough to perform in an industrial environment – and small enough for the very limited space on an integrated printed circuit board (PCB). For high-quality industrial sensors, have a look at Infineon's offering.

Autonomous production is an important component of the smart factory

Industrial automation for IIoT

The future of industrial automation is brimming with new opportunities to develop superior processes and deliver better products to customers.

During the last years, we've seen everything from a rush on hygiene products and food due to lockdown announcements to a significant shortage of semiconductor chips. These circumstances have led more and more manufacturers to consider ways to optimize their manufacturing processes. This hype in the field of industrial automation is being fueled by other trends mostly triggered by digitalization and sustainability goals - like the demand for power-efficient and industrial grade components with guaranteed long-term availability.

The orientation to the trends poses major challenges for many industrial companies.

- Manufacturing and process control: Shortening the production time to achieve faster throughput.

- Robustness, safety, reliability: Extended life cycle of equipment for less energy and raw material consumption.

- Real-time connectivity: Interoperability of all devices and controls for seamless data flow and continuous data transparency.

- Advanced sensor technologies: Optimization of production flow for early detection of defects.

Infineon provides its customers with the right technologies and innovations to address current and future security, functionality, connectivity and performance demands for industrial automation in smart factories. We offer high-quality industrial grade semiconductors along with a range of proven reference designs. All this makes your automation design as simple, efficient, and reliable as possible.

Keeping a finger on the pulse of industrial developments

For smart factories of the future

To remain competitive in the future, it is important to continuously look for technological developments and innovative ways to improve processes and efficiencies while being prepared for disruptions and unpredictable scenarios. Dive in and learn more about exciting topics like machine vision, predictive maintenance and more.

Innovations in industrial manufacturing are developing rapidly. Major trends in Industry 4.0 are fundamentally the further development of IIoT products, high-performance sensors and actuators, and artificial intelligence applications. Digital Twin technology will continue to enrich industrial processes and put them to the test. In addition, the topic of energy efficiency, for example in the field of robotics and automation, will continue to be pushed both by researchers and within industrial companies. In order to guarantee resilient supply chains, the trend in terms of locating production sites is clearly moving in the direction of reshoring.

More important developments in smart factory technology

Machine vision systems in industrial automation are based on digital sensors built into industrial cameras with special optics. These capture images by means of which computer hardware and software can process, analyze and measure various features for decision-making.

Modern industrial automation systems make use of machine vision (MV) system at their factory floor to control processes, quality, throughput or deviations in manufacturing process. Machine vision typically is a collaboration of hardware and software, based on object or pattern recognition. Artificial intelligence along machine learning, leads to a manufacturing process reaching highest productivity level, reduces production costs and helps to achieve repeatable outputs. Unmatched quality and long-term supply agreements, as well as a strong commitment to future investment in new technologies, Infineon will continue to lead the industry for decades to come.

Explore our products and solutions for machine vision systems.

Robots have joined the ranks of innovative and disruptive technologies by revolutionizing traditional habits and processes. Today’s robots can identify and navigate through surroundings, work alongside and even interact with humans. Moreover, they teach themselves the skills required to complete a new task.

According to ABI Research, shipments are expected to grow at a CAGR of 4.5% in 2030 compared to 2020 - for cobots, the expectations are as high as 43%! All this would not be possible without semiconductor solutions. Whether in an industrial robot, a collaborative robot (cobot), a mobile robot for warehouses, last-mile delivery (AGV & AMR) or a domestic robot, intelligent semiconductors are the key enablers for all major robotic functions.

As both a leading supplier of robotic components and an advanced user of robots in our own fabs, we at Infineon have carved out a unique position on the market. We provide a huge market-leading and comprehensive portfolio of power products, sensors, connectivity, and microcontrollers for industrial robots, cobots, mobile robots and more - everything from one single source.

Power electronic components, such as IGBTs and CoolSIC™ MOSFETs, including fitting EiceDRIVER™ gate driver solutions across various power ranges, support a wide range of robotic payloads. CoolMOS™ and CoolSIC™ MOSFETs as well as auxiliary power supply solutions such as CoolSET™ enable efficient power management. PSoC™ microcontrollers are applicable for system control and are also equipped with peripherals to enable connectivity via CAN, USB, or Wi-Fi based on the AIROC™ Wi-Fi & Combos offering. They are also well suited to interface with XENSIV™ sensors to sense the robot’s surroundings. Our range of external memory solutions for code storage and data logging enables the highest reliability, performance, and safety standards. Finally, the OPTIGA™ Trust hardware security solutions provide highly flexible, high-performance, secured access to the cloud.

Predictive maintenance offers the potential to optimize maintenance tasks in real time over system lifetime, maximizing the useful life of equipment while still avoiding disruption to operations.

With the help of the data collected in smart factories, predictive maintenance is possible - with great potential for reducing costs. In predictive maintenance, software analyzes the status data of machines and systems. It detects deviations from standard values, error patterns, and low-quality components - and can thus predict faults or technical defects. This enables the service department to react in good time and proactively prevent a costly machine failure. To do this, for example, it installs a new spare part or brings forward maintenance work. The runtime of the equipment can also be extended as a result.

Explore Infineon's broad portfolio and partner network for reliable data collection and processing enabling condition monitoring and predictive maintenance across diverse industry 4.0 use cases.

Artificial Intelligence in smart factories is expected to continue to play a key role in the future, along with related technologies such as machine learning.

AI technology can be used for more accurate forecasting and planning in the areas of maintenance, production capacity, inventory, sales and more. AI also plays a critical role in the development of virtual twins. These simulations of factory environments are updated in real time based on data collected from IIoT devices, allowing technicians to visualize layouts and workflows. This also allows them to optimize performance remotely.

As new business models emerge in the era of connectivity, industrial security is critical. That’s why it’s vital to find a strong partner with high-quality, reliable security technologies for your IIoT applications.

Security is of critical importance within an isolated production plant and even more so in an interconnected industrial value chain. Advantages when you source a solution from Infineon, are flexibility, so you can scale security functions from small systems to industrial-size installations, a robust, reliable performance, and easy to integrate solutions based on open standards.