MIL-PRF-38535 Screening and Quality Conformance Inspection Requirements

MIL-PRF-38535 covers screening requirements that all parts are submitted to as well as Quality Conformance inspection consisting of one or more of Group A, B, C and D for acceptance of the design of the process and of the production lot.

MIL-PRF-38535 applies to microcircuits such as integrated circuits (IC).

For more information on MIL-PRF-38535 screening and quality conformance inspection, consult the DoD document or contact factory.

IR HiRel screens IC devices to IR HiRel’s Qualified IR List (QIRL) with S and B-level equivalent screenings. QIRL part numbers have SCS and SCB suffixes.

Wafer Lot Acceptance:

MIL-PRF-38535 QCI Group Steady State Life Test, both Class Level B and S

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 1 |

Wafer Probe |

Static @ 25ºC |

100% |

| 2 |

SEM Inspection |

2018 |

2 Wafers each Lot 10 (0) die |

| 3 |

a. Steady-state life test (QCI life test coverage), 1,000 hours HTRB at 125ºC (Note 1) b. End-point electrical parameters |

1005 |

45 (0) |

Note 1 - Stage 1 life test (1,000 hours @125C) is performed on each wafer lot as part of wafer lot acceptance. A sample of 5 die from each wafer (45 die minimum from each wafer lot) will be subjected to 1,000 hours life test, similar to element evaluation requirements in MIL-PRF-38534, Class K. The steady state life test is performed and applied for QCI coverage; both Group C (class level B devices) and QCI Group B5 (class level S devices).

Screening:

MIL-PRF-38535 Test & Screening Requirements

| Test/Inspection | Screening Class Level | MIL-STD-883 | ||

| COTS | B | S | ||

| Non-destructive bond pull (pre-seal) |

3 (0) min. |

3 (0) min. |

5 (0) min. |

2023 (Note 1) |

| Internal visual inspection (pre-seal) |

AQL Cond. B |

100% Cond. B |

100% Cond. A |

2010 (Note 2) |

| Temperature cycling |

- |

100% |

100% |

1010, condition C (alternate) 20 cycles, -55ºC to 150ºC (Note 3) |

| Particle impact noise detection (PIND) |

- |

- |

100% |

2020, condition A (Note 4) |

| Constant acceleration |

- |

100% |

100% |

2001, condition E 30KG, Y1 orientation for 1 min. |

| Serialization & Case Mark (lot ID) |

100% |

100% |

100% |

Refer to marking drawing (Note 5) |

| Pre burn-in electrical parameters @ 25ºC |

- |

100% |

100% |

Read & Record |

| Burn-in Continuity Verification |

- |

- |

100% |

Inspection with data record |

| Burn-in (dynamic) |

- |

- |

100% 240 hours |

1015, condition D, at 125ºC |

| Post burn-in (interim) electrical parameters @ 25ºC |

- |

- |

100% |

Test within 96 hours, Read & Record w/ Delta’s, PDA limit 5% (3% functional parameters) |

| Burn-in Continuity Verification |

- |

- |

100% |

Inspection with data record |

| Burn-in (static HTRB) |

- |

100% 160 hours |

100% |

1015, condition A, at 125C |

| 160 hours |

||||

| Post burn-in (final) electrical parameters @ 25ºC |

- |

100% |

100% |

Test within 96 hours, Read & Record w/ Delta’s, combined PDA limit 5% (3% functional parameters for Class S) |

| Outlier identification test (OOF) |

- |

100% |

100% |

Remove all outliers |

| Post burn-in (final) electrical parameters @ 125ºC and -55ºC |

- |

- |

100% |

Read & Record |

| Hermetic seal test (gross / fine leak) |

100% |

100% |

100% |

1014 |

| Radiography |

- |

- |

100% |

2012, 2 views |

| Lead tinning |

100% |

100% |

100% |

SnPb base solder |

| Hermetic seal test (gross / fine leak) |

100% |

100% |

100% |

1014 |

| Particle impact noise detection (PIND) |

- |

- |

116(0) |

2020, condition A |

| Electrical test, Go-no-go @ 25ºC |

100% |

100% |

100% |

|

| External visual inspection |

(Note 6) |

100% |

100% |

2009 |

| QCI (TM5005) & Lot acceptance review |

- |

100% |

100% |

Plant clearance - hold inspection lot |

| Packaging and labeling |

100% |

100% |

100% |

ESD Caution apply |

Note 1 - Use of alternate SPC Test Method and process controls instead of 100% nondestructive bond pull. Destructive bond pull test is performed with SPC derived limits and inspection. One (1) device is pre-conditioning @ 300ºC for 1 hour to verify aging reliability of wire bonds.

Note 2 - COTS: Use ANSI/ASQC Z1.4 Attributes Tables, General Inspection Level II, Double Sample, 0.65% AQL. If sample is rejected, then perform 100% pre-cap inspection.

Note 3 - Use of alternate Temperature Cycle Test Method instead of 10 cycles (-65ºC to 150ºC). Temperature cycle is performed with 20 cycles (-55ºC to 150ºC).

Note 4 - PIND test may be performed in any sequence after temperature cycling test and prior to post burn-in (interim) electrical parameters test.

Note 5 - Serialization only applies to Class Level S devices.

Note 6 - Perform random sample inspection of lot. For lot size < 500 pcs, inspect sample of 22(0) and for lot sizes ≥ 500 pcs, inspect sample of 45(0). If one defective is found, apply double sample inspection (additional 22 or 45 pcs), and if more than 1 defective inspect entire lot.

Quality Conformance Inspection:

MIL-PRF-38535 QCI Group A Testing, Class Level B and S

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 1 |

ATE Static tests at +25°C |

3003 3004 3005 3006 3009 3010 3021 |

116 (0) |

| 2 |

Static tests at max. rated operating temp. |

116 (0) |

|

| 3 |

Static tests at min. rated operating temp. |

116 (0) |

|

| 4 |

ATE Dynamic tests at +25°C |

116 (0) |

|

| 5 |

Dynamic tests at max. rated operating temp. |

116 (0) |

|

| 6 |

Dynamic tests at min. rated operating temp. |

116 (0) |

|

| 7 |

ATE Functional tests at +25°C |

116 (0) |

|

| 8 |

Functional tests at max. & min. rated operating temp. |

116 (0) |

|

| 9 |

ATE Switching tests at +25°C |

116 (0) |

|

| 10 |

Switching tests at max. rated operating temp. |

116 (0) |

|

| 11 |

Switching tests at min. rated operating temp. |

116 (0) |

ATE TM reference: 3003 -Delay measurements, 3004 -Transition time measurements, 3005 -Power supply current, 3006 -High level output voltage, 3009 -Input current, low level, 3010 -Input current, high level and 3021 -High impedance (off-state) high-level output leakage current.

MIL-PRF-38535 QCI Group B Testing, Class Level B only

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 2 |

Resistance to solvents (Note 1) |

2015 |

3 (0) |

| 3 |

Solderability, steam age (8 hours), solder temp 245C +/-5ºC |

2003 |

3 device min. and 22 (0) Leads |

| 5 |

a. Bond strength: (1) Thermo compression, cond. C or D (2) Ultrasonic, cond. C or D (4) Beam lead, cond. D |

2011 |

4 device min. and 15 (0) wires |

| b. Die shear test or stud pull |

2019 or 2027 |

3 (0) |

Note 1 - Resistance to solvents testing required only on devices using inks as a marking medium. Testing for laser marked devices is performed in QCI Group D.

MIL-PRF-38535 QCI Group B Testing, Class Level S only

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 1 |

a. Physical dimensions |

2016 |

3 (0) |

| b. Internal water vapor (cavity packages), 5,000 ppm max. (Note 1) |

1018 |

3 (0) or 5 (1) |

|

| 2 |

a. Resistance to solvents (Note 2) |

2015 |

3 (0) |

| b. Internal Visual and Mechanical |

2013, 2014 |

2 (0) |

|

| a. Bond strength: (1) Thermo compression, cond. C or D (2) Ultrasonic, cond. C or D (3) Beam lead |

2011 |

4 device min. and 15 (0) wires |

|

| b. Die shear test or stud pull |

2019 or 2027 |

3 (0) |

|

| 3 |

Solderability, steam age (8 hours), solder temp 245C +/-5C |

2003 |

3 device min. and 22 (0) Leads |

| 4 |

a. Lead Integrity, cond. B2 or D (LCC) |

2004 |

3 device min. and 45 (0) leads or 15 (0) pads |

| b. Seal (fine and gross) |

1014 |

||

| 5 |

a. Steady-state life test (Note 3) |

|

12 (0) small lot 22 (0) large lot |

| Alternate: 340 hours burn-in w/ life test coverage @WLA b. End-point electrical parameters |

1005 |

||

| 6 |

a. Temperature Cycling, cond. C, 100 cycles, -55ºC to 150ºC |

1010 |

15 (0) |

| b. Acceleration, cond. E, 30KG, Y1 orientation for 1 min. |

2001 |

||

| c. Seal (fine and gross) |

1014 |

||

| d. End-point electrical parameters |

Part spec. |

Note 1 - Not required for qualification or quality conformance inspections where group D inspection is being performed on samples from the same inspection lot.

Note 2 - Resistance to solvents testing required only on devices using inks as a marking medium. Testing for laser marked devices is performed in QCI Group D.

Note 3 – Stage 2 life test is performed at the packaged product level in QCI group B5 for Class S inspection lots. A sample is submitted to 340 hours burn-in at 125ºC. Sample inspection for small lots will be 12 parts, and 22 parts for large lots. Small lots shall not exceed 1,000 parts. Group B5 life 1,000 hour life is not required to be performed on production lots when covered at Wafer Lot Acceptance (Stage 1) and all the following conditions are met:

(a) Subsequent production lots utilize die from the same wafer lot as the initial production lot.

(b) Wafers or die remaining from the initial production lot are to be stored in dry nitrogen or equivalent controlled storage, and

in covered containers.

(c) No major changes to the assembly processes have occurred since the group WLA (B5/C) test was performed on the wafer lot.

Quality Conformance Inspection (continued):

MIL-PRF-38535 QCI Group C Testing, Class Level B only

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 1 |

a. Steady-state life test (QCI life test coverage), 1,000 hours HTRB at 125ºC (Note 1) b. End-point electrical parameters |

1005 |

45 (0) |

Note 1 – Group C life test (1,000 hour) is not required to be performed when covered at Wafer Lot Acceptance.

MIL-PRF-38535 QCI Group D Testing (26 weeks), Class Level B and S

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 1 |

Physical dimensions |

2016 |

15 (0) |

| 2 |

Lead Integrity, cond. B2 or D (LCC) |

2004 |

3 device min. and 45 (0) leads or 15 (0) pads |

| Seal (fine and gross) |

1014 |

||

| 3 |

Thermal Shock, cond. B, 15 cycles, -15ºC to 125ºC |

1011 |

15 (0) |

| Temperature Cycling, cond. C, 100 cycles, -55ºC to 150ºC |

1010 |

||

| Moisture resistance |

1004 |

||

| Visual (3X magnification) |

1004/1010 |

||

| Seal (fine and gross) |

1014 |

||

| End-point electrical parameters, < 48hours from moisture resistance |

Part spec. |

||

| 4 |

Shock, cond. B, 1500G, 0.5ms, 5 shocks in each x, y, z axis |

2002 |

15 (0) |

| Vibration, cond. A, variable frequency, in each x y, z axis |

2007 |

||

| Acceleration, cond. E, 30KG, Y1 orientation for 1 min. |

2001 |

||

| Seal (fine and gross) |

1014 |

||

| Visual (3X magnification) |

2007 |

||

| End-point electrical parameters |

Part spec. |

||

| 5 |

Salt atmosphere, cond. A, pH level 6.5-7.2, 95F, 10-50 g/m2/day |

1009 |

15 (0) |

| Visual |

1009 |

||

| Seal (fine and gross) |

1014 |

||

| 6 |

Internal water vapor (cavity packages), 5,000 ppm @ 100C |

1018 |

3 (0) or 5 (1) |

| 7 |

Adhesion of lead finish (NA for LCC), bend leads 90 degrees |

2025 |

3 device min. and 15 (0) leads |

MIL-PRF-38535 QCI Group E Testing, Class Level B and S (Rad hard IC only)

| Sub Group |

Parameters | MIL-STD-883 Test Method | Quantity (accept number) |

| 2 |

a. Total ionization dose (TID) @ 25ºC, cond. A @ 50-300 rad(Si)/s b. End point electrical parameters test |

1019 |

4 (0) ea. wafer |

| 5 |

a. Single event effects (SEE) typical response, at qualification or major change b. End point electrical parameters test |

ASTM F-1192 or JESD57 |

5 (0) |

Product ID Reference:

Screening Designators (PN suffix):

| --- (blank) |

SCB |

SCS |

| COTS |

Class B IAW MIL-PRF-38535 |

Class S IAW MIL-PRF-38535 |

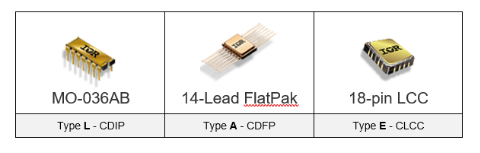

Package Types and Designators:

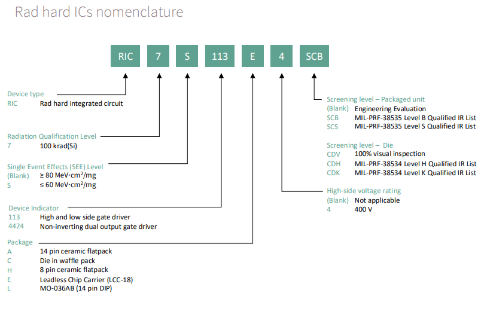

Part Number Nomenclature: