iMOTION™ Integrated Motor Control Solutions Highly integrated products for the control of a variable speed drive (VSD)

iMOTION™ is a family of highly integrated products for the control of a variable speed drive

iMOTION™ ICs integrate all the control and analog interface functions required for sensor less field oriented control (FOC) of PM motors using DC link or leg shunt current measurements. In addition they feature Infineon’s patented and field proven motion control engine (MCE) that eliminates software coding from the motor control algorithm development process. Implementing a variable speed drive is reduced to configuring the MCE for the respective motor. Assisted by the powerful tool iMOTION™ Solution Designer (iSD) it is possible to have the motor up and running in less than an hour.

The iMOTION™ family consists of the iMOTION™ controllers, the iMOTION™ drivers and the iMOTION™ IPMs.

Solution Designer as new tool for iMOTION™ motor control solution

Integrated GUI-based iMOTIONTM tool to simplify the design of inverterized drives.

Our Developer Community is available 24x7 for you to connect and network with engineers across the globe. Get help from our support engineers, and expert members to solve your design challenges anytime, from anywhere, in any topic, and in your preferred language.

Aimed at offering customers the best fitting solution the iMOTION™ family offers several levels of hardware integration. In addition to the stand-alone MCE control IC Infineon is offering variants with an additional microcontroller.

The highest integration level is achieved in the IPM family members. The combination of the MCE together with the gate driver and a three phase full bridge results in a complete inverter system in one small PQFN package. By integrating both the required hardware and software to perform sensor less control of a permanent magnet synchronous motor (PMSM) they provide the highest energy efficient appliance motor system with the lowest system cost.

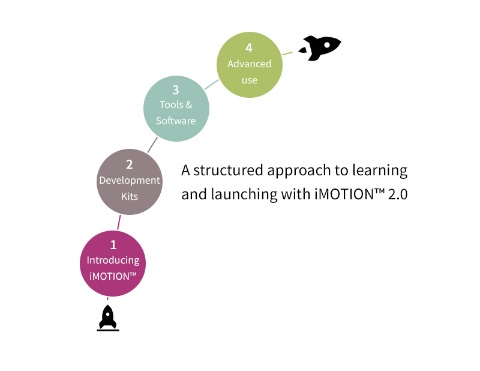

From novice to expert with iMOTION™

This guide [en] [cn] provides a structured, sequential approach to learning iMOTION™. It will serve as a syllabus listing resources available at each stage of working with iMOTION™ products. The document begins with highlights of iMOTION™ products and their features. Resources around evaluating the products and prototyping your system with iMOTION™ follow. The next stage describes the iMOTION™ tools and the final one lists resources describing advanced usage of iMOTION™.

This might also interest you

Find out what iMOTION™ Solution Designer offers you, how projects are created and the work flow in terms of configuration, tuning, dashboards and scripting. The tool guides you through the complete project workflow, achieving the shortest time to market with the lowest R&D efforts.

Infineon´s iMOTION™ family consists of highly integrated products for the control of variable speed drives. Learn more about the benefits and the integration levels in this video.

Learn all about iMOTION™ 2.0 and how quickly you can get a motor up and running with this easy to follow video tutorial. This getting started guide first goes over a typical 3-phase motor drive set-up utilizing Infineon’s MADK system solution platform then dives into using the iMOTION™ tools (MCEWizard and MCEDesigner) to configure your iMOTION™ controller as well a run and tune your motor drive set-up.

State of the art sensorless algorithm for permanent magnet motor control is described in this video.

Common pitfalls of sensorless control, such as a non-controlled startup are easily avoided with the

Motion Control Engine (MCE) inside infineon iMOTION devices.

A clean startup, without vibrations and oscillations is demonstrated with a low inertia fan motor.

To help designers master these challenges and relieve the burden of complex software and hardware design, Infineon's broad portfolio is offering full solution for these types of systems, based on iMOTION™ motion control ICs and CIPOS™ Intelligent Power Modules (IPM). This webinar will present Infineon's solution to complex and compact FOC systems designs.

iMOTION™ ICs integrate hardware and software functionality required for controlling PMSM motors with field-oriented control (FOC) (with and without sensors). iMOTION™ products are based on Infineon’s patented, field-tested Motion Control Engine (MCE), which eliminates software coding from the development process. As a result, all users have to do to implement a variable speed drive is configure the MCE for the respective motor drive system.

As variable speed motor control expands into areas where simple on/off motor control traditional reigned, Infineon provides a turnkey “No C-Code” variable speed development solution to quickly and easily design motor drive systems. This presentation highlights the technical features & benefits of the solution as well as describes how the straight forward development process works.

Discover how Infineon’s Modular Application Design Kit, or MADK evaluation platform, covers 3-phase motor drive applications with a power level that goes from 20 Watt up to 10 kilowatt.

Infineon offers different solutions for low noise, small, and energy-efficient aircon fan units.

In this training you will get an overview of Infineon's iMOTION™ and CIPOS™ IPMs for both indoor and outdoor unit fans.

The iMOTION™ Solution Designer bundles all PC-based support functions related to setting up and running iMOTION™ products. This includes the configuration, programming and live tuning using configurable oscilloscopes as well as script editing and debugging. This training will help you get started with iMOTION™ Solution Designer.

Infineon's iMOTION™ family provides active power factor correction integrated digital motor control solutions for different product platforms, including iMOTION™ controllers, iMOTION™ drivers, and iMOTION™ IPMs.

Learn more about the iMOTION™ IPM IMI110 series which is a highly integrated, feature-optimized motor control solution to easily design-in and with a ready-2-use Software, the iMOTION™ solution designer.

You will find out what MADK boards are and what are their advantages regarding inverterization.