The future belongs to electromobility: This technology ensures that eco-friendly, quiet and efficient vehicles will be on our roads. There are still certain challenges to be overcome so that the many advantages of the electronic powerchain can be leveraged. But the breakthrough will come about.

Climate change, oil shortage, air pollution: Mobility has to be CO2-neutral in the future. E-cars and hybrid vehicles emit fewer exhaust gases than cars with combustion engines, if any. Electromobility is therefore an important way of enabling that – as long as the power is obtained from renewable energies. The IEA predicts that electric vehicles will have a market share of roughly 30 percent by 2030, with a total number of 34 million e-cars on the roads. But what does switching to electromobility actually mean, and what are its consequences?

What is electromobility?

Electromobility is the use of electric cars, as well as e-bikes or pedelecs, electric motorbikes, e-buses and e-trucks. The common feature of all of them is that they are fully or partly driven electrically, have a means of storing energy on board, and obtain their energy mainly from the power grid. Electric cars are quiet, efficient and low-emission and have mainly been used to date in cities, where they’re ideal for delivery services, taxis and car sharing.

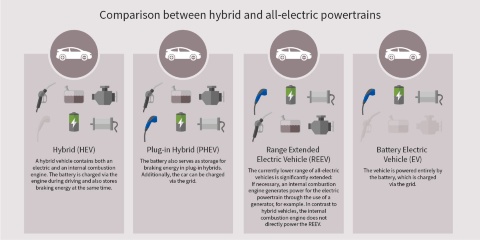

Hybrid vehicles combine two powertrain technologies. They can usually cover shorter distances with their electric drive, but their combustion engine means they can also manage long journeys without any problem. Hybrid cars that not only use the electricity recovered when they taxi or brake, but can also be recharged from the socket, are termed plug-in hybrids. Hybrids are regarded as a bridging technology until a time when cars can be fully powered by electricity.

Why is electromobility so important at present?

Emissions are having a serious impact on the climate and environment: More and more CO2 is entering the atmosphere, with the result that the Earth is becoming warmer and warmer. According to a survey by the Intergovernmental Panel on Climate Change (IPCC), traffic is responsible for 24 percent of all CO2 emissions worldwide. Electric vehicles counter that: Unlike gasoline and diesel cars, they don’t emit any CO2 when driven. Yet: E-cars are CO2-neutral in the full sense of the word only if the batteries and the electricity to power them are produced using renewable energies.

Low-emission cars also mean better air quality and therefore have a positive effect on people’s health – especially in conurbations. And the number of people living in cities will grow: The UNO’s World Urbanization Prospects 2014 report concludes that almost 70 percent of the world’s population will live in urban regions by 2050.

Combustion engines are on the way out because fossil fuels like oil, from which gasoline and diesel are produced, are finite resources. How long these sources will last is a moot point. According to the study “Statistical Review of World Energy 2017”, the world’s currently known oil reserves will last almost 50 years given current levels of consumption. To enable alternative forms of powertrain to become established, many countries offer incentives to buy e-cars – Norway, for example, subsidizes them greatly.

How does an e-car work?

The design of an electric drive

Electrical energy is stored in a rechargeable battery. Devices termed inverters convert the battery’s direct current into alternating current for driving the electric motor. The more efficient conversion is, the longer a car can travel when a battery is fully charged. Finally, an electric motor converts electrical energy into mechanical energy: The e-motor obtains this energy to generate magnetic fields. Their attractive and repellent forces produce a rotational motion.

Other core components of an e-car are the DC-DC converter. It converts the battery’s high voltage (100-400 volts or more) efficiently into a far lower voltage (12 or, if applicable, 48 volts) for electronic components.

How is an e-car recharged – and how long does that take?

E-cars have to be charged from the socket to stay mobile. 80 percent of owners recharge them from the socket at home, according to a study by the German Federal Association for eMobility. That takes at least eight hours, depending on the vehicle and battery. However, not every socket is designed to handle large amounts of electricity flowing over a lengthy time. That problem is solved by wall boxes at home, which make recharging almost four times faster. Charging a battery at public alternating current (AC) stations takes just as long, whereas only one hour is needed at direct current (DC) fast charging stations. The reason: The battery in an e-car has to be charged with direct current, but the electricity from the public grid is alternating current. The car’s inverter first has to convert it. That’s why charging at AC stations takes longer than at DC ones. The latter convert the electricity into direct current before charging and pass it on directly to the car’s battery. These fast DC charging stations enable high charging performance, but are rarer at present because they are more expensive. A special cable is required to use both types of charging station. The time needed to charge a car will soon be reduced to 20 minutes or less thanks to efficient technology such as ultra-high-power chargers and improved batteries.

How much electricity does an e-car consume?

An e-car’s consumption is measured in kilowatt hours (kWh) per 100 kilometers. Very small e-cars with a low weight can have a low consumption of less than 7 kWh per 100 kilometers. Other sub-compact and compact cars roughly consume between 11 and 13 kWh per 100 kilometers. Premium brand e-cars can sometimes “guzzle” 28 kWh. Nevertheless, some of them are able to travel up to 600 kilometers thanks to their particularly large batteries.

The development of electromobility to the present day

Electromobility is regarded as a modern trend, but to be precise, it’s not an invention of our times. Way back in 1867, and hence before the advent of the combustion engine, Werner von Siemens presented his electric generator based on the dynamo-electric principle at the World’s Fair in Paris. The invention enabled low-cost, flexible generation of electricity wherever it was needed and thus electrification in everyday life, industry – and vehicles.

The first cars with an electric motor were presented at the end of the 19th century. That from the Belgian Camille Jenatzy even set a record in 1899: It was the first road vehicle of any kind to reach a speed of 100 km/h. From the end of the 19th century, trains and trams were supplied with energy by overhead lines or power rails. As figures from the year 1900 show, e-cars were still widespread at the start of the 20th century: 22 percent of vehicles on U.S. roads had a combustion engine, 40 percent were steam-driven, and 38 percent were electrically powered. The combustion engine had a disadvantage back then: Vehicles had to be cranked up at considerable effort to get started. Gasoline drives did not begin to displace other types of powertrain until 1911, when the electric starter was invented.

From then on, e-vehicles were relegated to a niche existence, although they never completely disappeared. In the mid-1990s, a hybrid model came on the market in the shape of the Toyota Prius. In 2008, a Californian Roadster became the first e-car on the road that was suitable for highways and lengthier distances.

Did you know? The first car was an e-car!

In 1881, the French engineer Gustave Trouvé presented a world’s first: A tricycle with an electric motor and battery. It could reach a speed of 10 km/h – which was considered perilously fast at the time. The first Benz car with a combustion engine was not presented until 1886.

How fast can an e-car travel today?

Because they have no transmission, all e-cars accelerate more constantly and faster than ones driven by gasoline or diesel. But what is the top speed they can reach? Smaller e-cars can get up to 120 km/h. Sports cars from the U.S. can accelerate to more than 300 kilometers per hour. One of the fastest e-cars in the world is from the Croatian manufacturer Rimac: Its Nevera model “roars” over the road at a speed of more than 400 kilometers per hour.

How far can an e-car currently travel?

Most of the current e-cars can travel between 150 and 350 kilometers on a single charge. That makes them ideal for the city. Only premium-brand models can currently cover more than 500 kilometers. However, the range depends on various factors: Low or high external temperatures drain the battery, as does the use of the radio or air-conditioning system. Constant acceleration and braking likewise reduces the range.

To what extent is electromobility already being used?

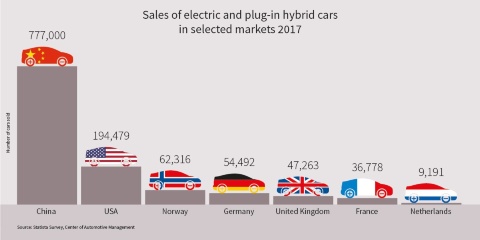

Electromobility is making advances worldwide. 395,000 e-cars and plug-in hybrids were sold in Germany in 2020, according the German Association of the Automotive Industry. In this regard, Germany ranks second in the world. The front-runner is China, where 1.25 million e-cars and plug-in hybrids were sold in 2020. The U.S. (302,000) and France (186,000) come in third and fourth, respectively.

Norway: the forerunner

Norway is the role model for electromobility: For the first time, more vehicles with a hybrid and electric drive than with a combustion engine were registered there in 2017 – thanks to massive subsidization. The government taxes conventional cars heavily, whereas no taxes are incurred if clean cars are purchased. Further benefits are lower vehicle tax and free use of toll roads and state-run ferries. From 2025, only zero-emission cars are to be sold in Norway.

More and more manufacturers are launching not only e-cars, but also commercial vehicles with an electric motor which are suitable for everyday use – e.g. the Mercedes e-Vito and the Renault Master Z.E. already entered the market in 2018.

Advantages of electromobility

Electric vehicles are changing the way we move – not only because they are more eco-friendly. An e-car costs more than a comparable gasoline or diesel vehicle – mainly due to the large costs of producing the battery, although its prices have fallen in the past years. However, electricity is cheaper than fossil fuels. Moreover, electric vehicles require less maintenance and fewer repairs. There’s no need to change the oil and filters, and there are no exhaust systems, timing belts or V-belts. A combustion engine has around 2,500 components that have to be made and assembled – compared with just 250 in an electric motor. E-cars can be serviced quickly by software updates over the air (SOTA). However, that’s also true of all connected cars, in other words, cars with access to the Internet.

The lithium-ion batteries used in e-cars have a long service life, boast a high energy density and can be recharged many times over. They lose some of their charging capacity after eight to ten years, but they aren’t defective: They simply store less energy. Most batteries in e-cars today have a capacity of 20 to 60 kilowatt hours.

The batteries in e-cars are to be used in future to stabilize smart grids. If the wind and sun provide most of our energy supply, there’s a problem: Supply and demand for electricity may diverge, depending on the weather. Intelligent car charging technology should then be used to absorb excess energy, for instance, when there is a lot of sunshine. Conversely, it can feed excess electricity back into the grid when it’s no longer needed in the car. By installing a photovoltaic system on the roof of their home, e-car owners can reduce dependence on external sources of power – and, with a wall box, eliminate the need to drive to a service station. An additional means of storage at home can also collect energy for times when the sun shines less.

Comparison between silicon carbide and silicon: Smaller battery, greater power

The electronics in e-cars must be powerful and efficient – they influence how far and fast the cars can travel. Power semiconductors made of silicon carbide (SiC) are setting new standards here. Silicon carbide can handle higher loads and stresses than silicon (Si) – and needs less energy for that, even at high temperatures. Electrical power can be converted in a far more efficient and compact manner thanks to higher switching speeds and lower conduction power losses than silicon-based components. The lower losses also mean that less cooling of the battery is required. That ensures higher efficiency and fewer heat sinks on the battery – making it smaller and lighter.

Electric cars deliver high performance and have a far higher efficiency than vehicles with a combustion engine: The ratio between the energy that is fed in and can be used is around 90 percent for electric powertrains. That figure is just 35 percent for gasoline engines and 45 for diesel engines. The rest is lost as heat, for instance. Further advantages: Due to the fact that a high torque is available immediately, e-cars can accelerate faster from 0. They can also obtain energy with the aid of the inverter, such as when they brake, and feed it back to the battery. This effect is called recuperation. E-cars have special rights in some countries and cities: In Germany, they can park free of charge in Hamburg and Stuttgart and use the bus lanes in Dortmund, for example. E-car drivers in Norway have even more privileges.

Since powerful car batteries are still very expensive, the price of e-cars is on average higher than that of comparable models with a combustion engine. But for whom is buying an e-car worthwhile? Germany’s Öko-Institut (Institute for Applied Ecology) has conducted a sample calculation: Assuming a distance traveled of 9,000 kilometers a year and a service life of eight years, the total cost of ownership of an e-car can be lower than a vehicle with a conventional drive. You can calculate that for yourself on the institute’s website.

Challenges facing electromobility

Despite its many advantages, there are other challenges relating to electromobility in addition to the fact that the price of an e-car is still high at present. E-cars are very quiet. That means a lot less noise, especially in cities and along main roads. Pedestrians and cyclists will have to get used to that first. However, if electric cars are moving at low speed, they are so quiet that they might not even be heard at all. That is why newly developed models in the EU have to be fitted with an Acoustic Vehicle Alerting System (AVAS) from July 2019 on: Up to a speed of 20 km/h, they have to generate electronic noises similar to those of gasoline or diesel cars. If the e-car is traveling faster, the noise made by its tires can be heard anyway. An AVAS is mandatory for all new electric and hybrid cars in the EU as of July 2021.

To ensure that e-cars are zero-emission in the full sense of the word, their electricity must come from renewable sources and not, for example, coal-fired power plants, while production of the battery must also be CO2-neutral. The use of renewable energies is also the objective of the German government: That is the only way “electromobility can fully unfold its advantages for the environment and climate,” it states in a dossier on the energy transition. According to the International Council on Clean Transportation (ICCT), electric cars will overtake diesel or gasoline ones in terms of climate footprint in three years’ time at the latest. If the costly, resource-intensive process of producing batteries becomes even more eco-friendly, that advantage will be even greater, states the research institute.

The attractiveness of electromobility stands and falls by the batteries: What distance can the cars cover with them, how much do they cost, what do they weigh? There’s room for improvement here. New technologies, as well as elements from the semiconductor material silicon carbide (SiC), are required to achieve higher efficiencies and top performance. The low range of e-cars at present deters many from buying one, according to a survey by the business consulting firm Deloitte. Yet most of us could now already use an electric vehicle for many of the journeys we make without any problem. Germans drive less than 40 kilometers on average on more than 80 percent of the days they use a car, states the Federal Ministry for the Environment. The average American travels 31.5 miles a day in the fall and 26.2 miles in the winter. The figure for Norwegians is around 47.2 kilometers a day on average.

Other respondents criticized the fact that the network of charging stations in Europe still needs to be improved. While there are currently 322,783 public charging stations, they are unevenly distributed. The top five countries with the most charging stations are the Netherlands (82,263), Germany (47,076), France (45,990), as well as the United Kingdom (33,832), and Norway (19,119). They account for more than 70 percent of the charging stations in Europe. Besides that, China currently operates around 800,000 public charging stations.

In the U.S., most charging points are in California: Los Angeles, San Francisco and San José. However, the charging infrastructure has differed so far from country to country and there is no consistent standard. The CharIN Initiative, of which Infineon is also a member, aims to change that: The efficient Combined Charging System (CCS) is to be developed into the single global standard.

Electromobility is one of the most exciting topics of today – and it is set to play an even greater role in the future. Do you want to help drive these developments? Then get in touch with us so that we can connect your creativity with our technology.

For all vacant positions in the field of electromobility, please visit our career website.

Do you want to know more about typical profiles that deal with electromobility at Infineon? Check out the exciting job of an Application Engineer or the work of a Produkt Marketing Manager.

Infineon’s contribution to electromobility

Guided by the principle “easier, safer and greener,” Infineon collaborates with manufacturers and suppliers to create the vehicles of tomorrow. And with success: Power chips from Infineon were found in the electric drivetrain in 17 of the 25 most-sold fully electric cars and plug-in hybrids in 2020.

Yet even though e-vehicles and plug-in hybrids are far more energy-efficient than cars with a conventional powertrain, there’s still quite a bit that has to be optimized. Power losses need to be minimized, power savings maximized, and overall performance increased. Infineon offers a wide range of power semiconductor components for the various systems. They cut the costs for the drive and electronics, yet increase energy efficiency. In general, demand for semiconductors will increase sharply as electromobility becomes more widespread. Infineon assumes that more and more components with silicon carbide power semiconductors will be used in new developments in the future – such as the charger in the car, the inverter or the DC-DC converter.

Infineon works closely with partners in the field of electromobility, such as BMW (i3 and i8), Hyundai and the Chinese start-up NIO. The latter company builds electric vehicles such as the ES8, which delivers 480 kilowatts of power, in Munich. Numerous components from Infineon are used in it and many other e-cars.

Faster charging, longer ranges

There is growing demand for technologies that enable faster charging and longer ranges for electric vehicles. They are two vital criteria in ensuring e-cars become established. Infineon has semiconductors for the internal power supply and a complete DC charging device. New charging stations use Infineon semiconductors which are intended to reduce the charging time to 20 minutes. New technologies based on silicon carbide (SiC) are essential in enabling fast charging.

Innovations like active battery balancing are already increasing battery capacity, range and service life by more than ten percent. However, there are even more possible approaches to increasing the efficacy of electric vehicles. That can be done, for example, by the battery supplying energy only when needed or by designing the air-conditioning and heating system to be as efficient as possible. Not least, charging e-cars demands a flexible switching structure; after all, the charger has to be able to cope with different voltage levels and current strengths in different countries. Infineon helps solve these and similar requirements with its broad range of powerful, yet energy-efficient components and know-how to match.

The e-car of the future

Despite all the highly promising forecasts, electromobility is still in its infancy – not only as regards its low market share to date, but also from a technical perspective. Electromobility will only live up to the hopes pinned on it if the price of cars and batteries falls, charging networks grow and also become more intelligent, and e-cars achieve a level of energy efficiency to make them ready for the market. A lot is happening, especially in terms of energy efficiency. Companies and researchers are continuously working to enhance batteries. Initial tests on a battery with an electrolyte based on water instead of lithium salts sound highly promising. A special saline solution doubles the water’s electrochemical stability. That might give rise to a safe, efficient and low-cost new battery technology.

Better batteries will increase the range and reduce charging time – two crucial incentives for users. A comprehensive network of charging stations is vital if electromobility is to become established. If more manufacturers build e-cars and batteries become cheaper, the vehicles could achieve the breakthrough within a few years’ time. That is why the physicist and electromobility expert Richard Randoll predicts: At least every tenth new car worldwide will be an electric one by 2022.

Conceivable alternatives to e-cars: Hydrogen vehicles

Hydrogen vehicles are likewise driven by an electric motor. However, they use a fuel cell instead of a battery. A chemical reaction between hydrogen and oxygen generates electricity. There are no emissions – the only by-product is steam. The problem to date: Hydrogen does not occur in nature in pure form and therefore has to be produced from water and natural gas at great cost.

The most important questions and answers at a glance

Electromobility is the use of electric cars, as well as e-bikes or pedelecs, electric motorbikes, and e-buses. The common feature of all of them is that they are fully or partly driven electrically, have a means of storing energy on board, and obtain their energy mainly from the power grid.

Electrical energy is stored in a rechargeable battery. Devices termed inverters convert the battery’s direct current into alternating current for driving the electric motor. The more efficient conversion is, the longer a car can travel when a battery is fully charged. Finally, an electric motor converts electrical energy into mechanical energy: The e-motor obtains this energy to generate magnetic fields. Their attractive and repellent forces produce a rotational motion.

Other core components of an e-car are the DC-DC converter.

Electric vehicles are more eco-friendly. If they battery is produced and charged with renewable energy, they are zero-emission. Electric vehicles require less maintenance and fewer repairs; they do not have many parts that wear out like the combustion engine has. A combustion engine has around 2,500 components that have to made and assembled – compared with just 250 in an electric motor. E-cars can also be serviced quickly by means of software updates.

The lithium-ion batteries in e-cars have a long service life, boast a high energy density and can be recharged many times over. By installing a photovoltaic system on the roof of their home, e-car owners reduce dependence on external sources of power A wall box at home eliminates the need to drive to a service station. Electric cars deliver high performance and have a far higher efficiency than vehicles with a combustion engine: The ratio between the energy that is fed in and can be used is around 90 percent for electric powertrains. That figure is just 35 percent for gasoline engines and 45 for diesel engines.

E-cars are so quiet at low speed that they might not be heard by pedestrians and cyclists. Up to a speed of 20 km/h, they will therefore have to generate artificial noises in the future. To ensure that e-cars are actually zero-emission, their electricity must come from renewable sources. There is room to improve the range electric cars can travel; the batteries do not yet operate ideally. Yet most car owners could now already use an electric vehicle for many of the journeys they make without any problem: They drive an average of less than 50 kilometers a day in many countries. Another problem is that the network of charging stations still needs to be improved. There is growing demand for technologies that enable faster charging and longer ranges for electric vehicles. Infineon has semiconductors for the internal power supply in the vehicle and a complete DC charging device. New charging stations use Infineon semiconductors which are intended to sharply reduce the charging time.

Many regard the combustion engine as being on the way out; given the current state of the art, the electric powertrain could replace it in the near future. To achieve that, however, the price of cars and batteries must fall, charging networks grow and also become more intelligent, and e-cars achieve a level of energy efficiency to make them ready for the market. Companies and researchers are continuously working to enhance batteries. That will increase the range and reduce charging time – two crucial incentives for users. In addition, the network of charging stations is being constantly expanded.

Last update: July 2021